Adjustable high accuracy rotating center

A technology of rotating top and height adjustment, which is applied in the direction of tailstock/top, turning equipment, toolholder accessories, etc., which can solve the problems of frequent replacement and easy loss of ball bearings, etc., achieve long service life, improve manufacturing level, and promote development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

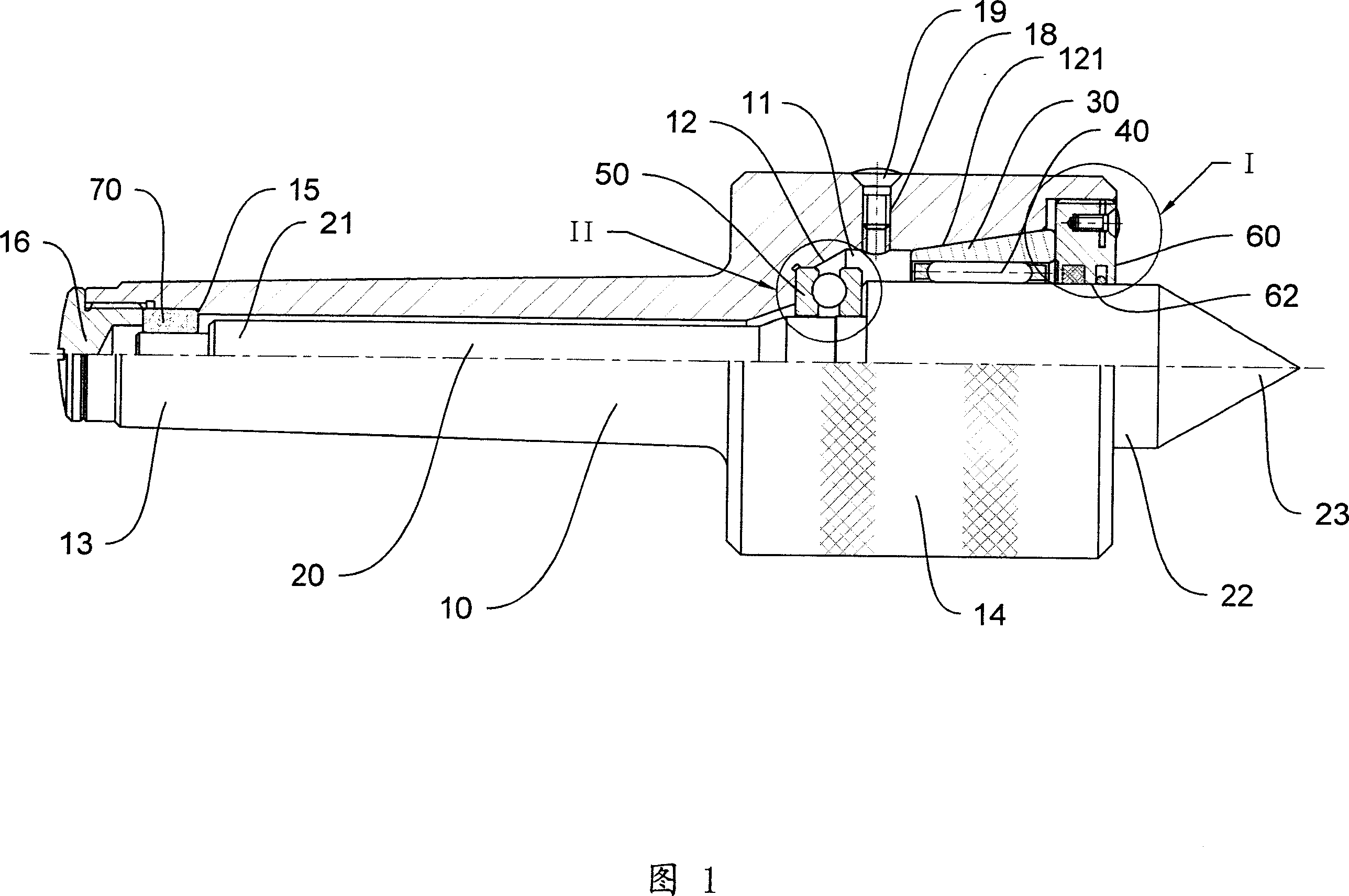

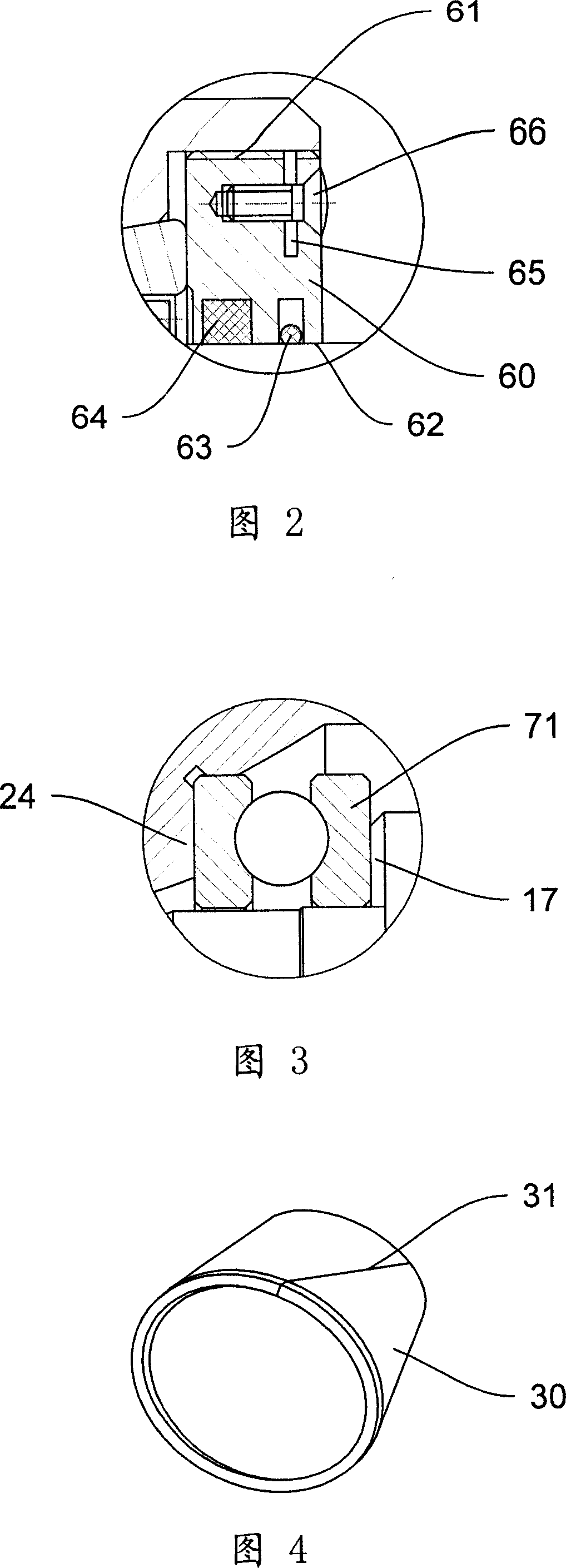

[0021] As shown in Figures 1, 2, and 3, in the preferred embodiment of the high-speed and heavy-duty rotary top of the present invention, it includes a sleeve 10 whose appearance matches the standard machine tool tailstock hole, and is sleeved in the inner cavity 11 of the sleeve. The mandrel 20, and the main bearing 40 and the intermediate bearing 50 that position the mandrel 20 on the side wall 12 of the sleeve cavity.

[0022] The sleeve 10 of the rotary center includes an insertion end 13 inserted into the tailstock hole of the machine tool and a clamping end 14 close to the workpiece. The inner end 21 of the mandrel is inserted into the inner cavity 11 of the sleeve, and the outer end 22 protrudes from the sleeve 10 and is provided with a conical tip 23 for clamping the workpiece. The main bearing 40 and the intermediate bearing 50 are both sleeved on the mandrel 20, wherein the main bearing 40 is preferably a bearing with cylindrical rolling elements, so that the contact...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap