Hydraulic pressure actuator

An actuation device, fluid pressure technology, applied in the direction of fluid pressure actuation device, etc., can solve problems such as inner tube damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Next, an embodiment of a fluid-type actuator that is a specific invention of the present invention will be described with reference to the drawings.

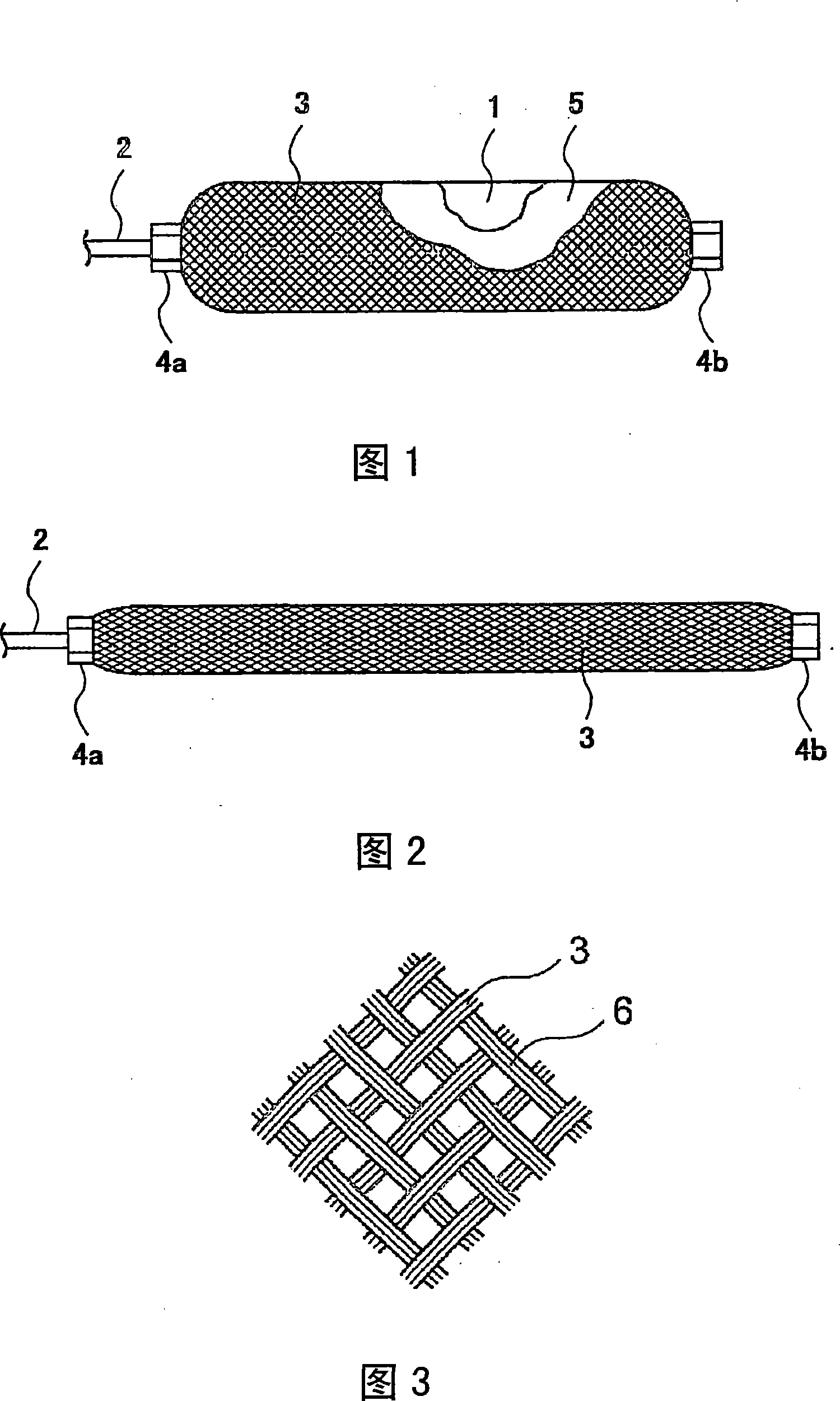

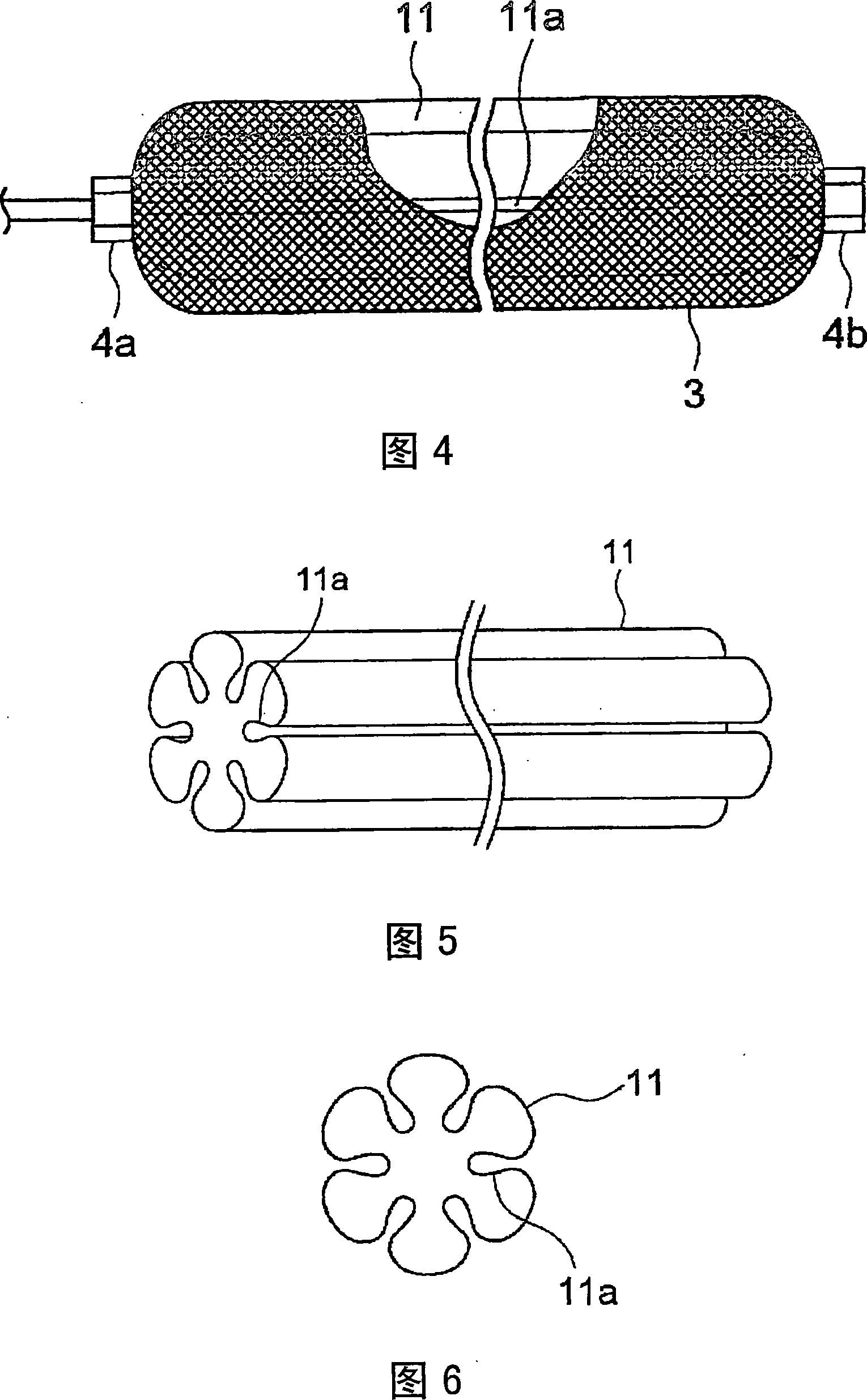

[0045] 1 is a side view showing an expanded state of Embodiment 1 of a fluid-type actuator using air as a fluid according to the present invention, and FIG. 2 is a side view showing a contracted state of the fluid-type actuator of FIG. 1 . In addition, in FIG. 1 , in order to show the internal structure of the pneumatic actuator, parts of the mesh sleeve and the low-friction body are shown by dotted lines.

[0046] In FIGS. 1 and 2 , an air supply and exhaust pipe 2 for supplying and discharging air as a fluid into and out of the inner tube 1 is connected to one end in the longitudinal direction of the inner tube 1 that is an expandable and contractible body. The other end of the inner tube 1 is airtightly sealed by inserting a bush (not shown). An air supply and exhaust device (not shown) composed of a small air compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com