Connector for modular

A technology of connectors and contact terminals, which is applied in the direction of connections, parts of connection devices, coupling devices, etc., can solve problems such as lack of elastic contact force, module tilt or shake, and lack of fixing devices, so as to reduce assembly The number of parts, the effect of increasing and suppressing tilt or vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

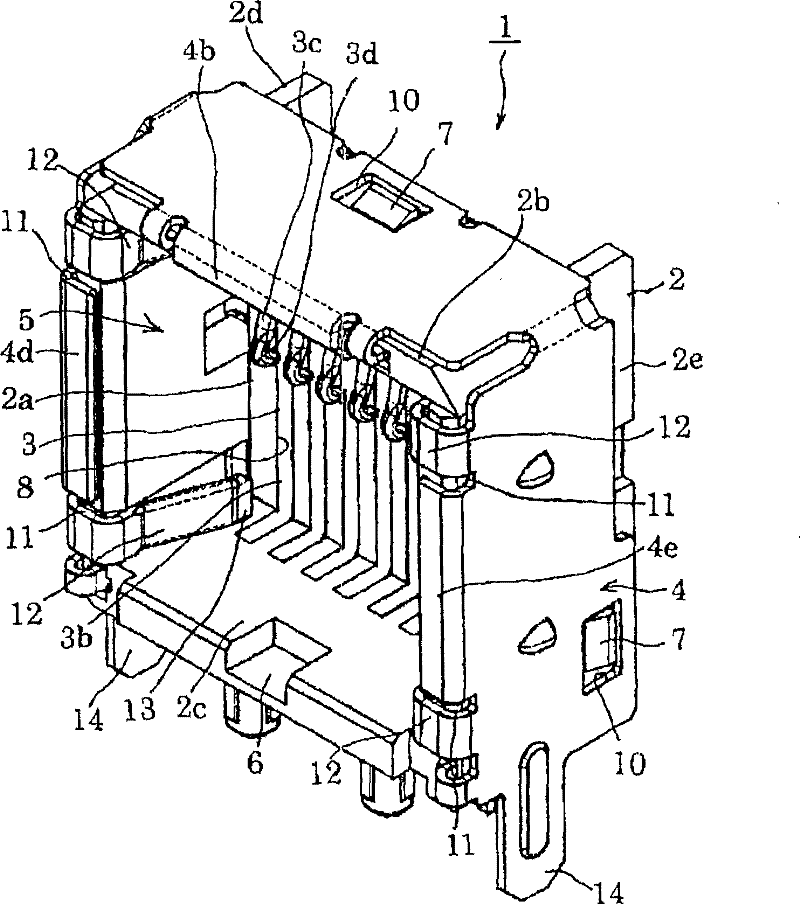

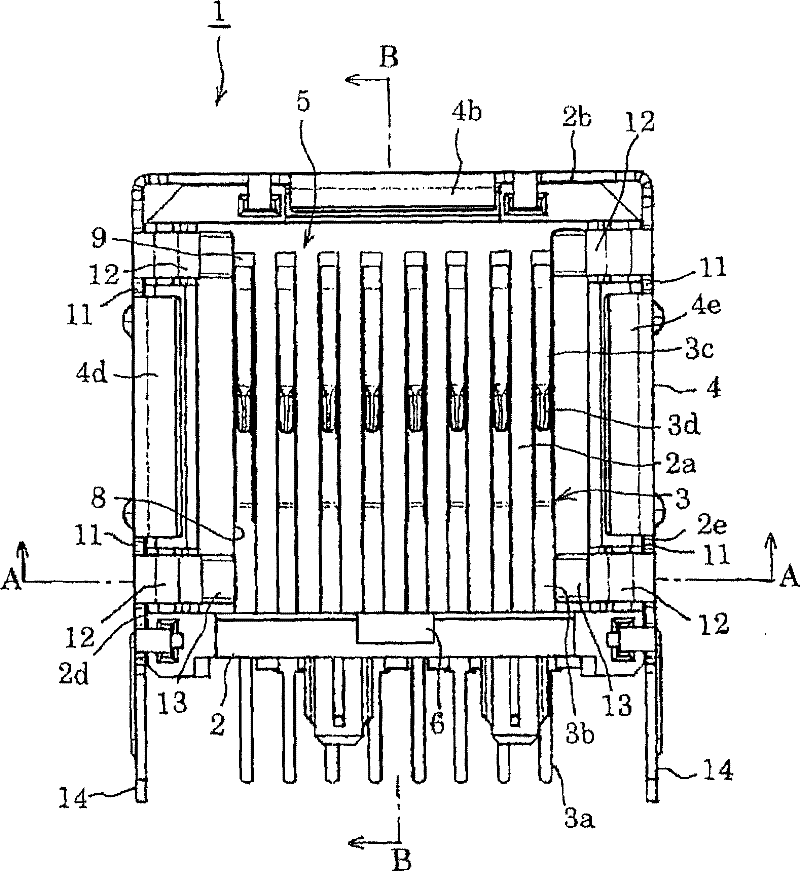

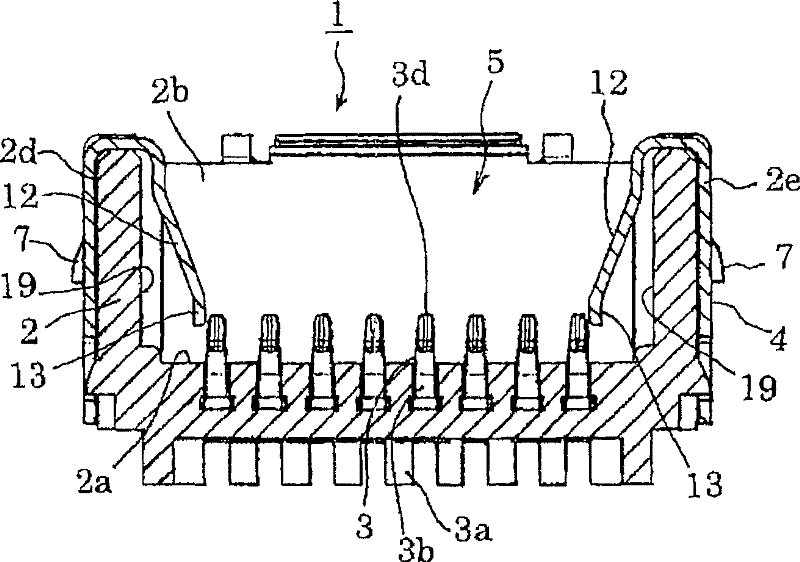

[0039] Below, based on Figure 1 ~ Figure 4 Embodiments of the module connector of the present invention will be described. Such as Figure 1 ~ Figure 4 As shown, the module connector 1 of the present embodiment is an example of a vertical type that is vertically mounted on a printed circuit board (not shown), and includes a housing 2, and a plurality of contact terminals are arranged inside the housing 2. 3, 3 . . . , the outer surface of the case 2 is covered with a metal shield 4 .

[0040]The casing 2 is an integrally molded product made of synthetic resin, and has a quadrangular rear panel 2a, an upper panel 2b extending forward from the periphery of the rear panel 2a, a bottom panel 2c, and left and right side panels 2d and 2e. The rear panel 2 a , the upper panel 2 b , the bottom panel 2 c , and the left and right side panels 2 d and 2 e constitute a substantially quadrangular square module housing portion 5 with an open front.

[0041] On the left and right central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com