Pipe clamp with improved fastener

A technology for fasteners and pipe collars, which is applied in the direction of threaded fasteners, fasteners, connecting components, etc., and can solve problems such as uncertain joint strength and inconsistent nut torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

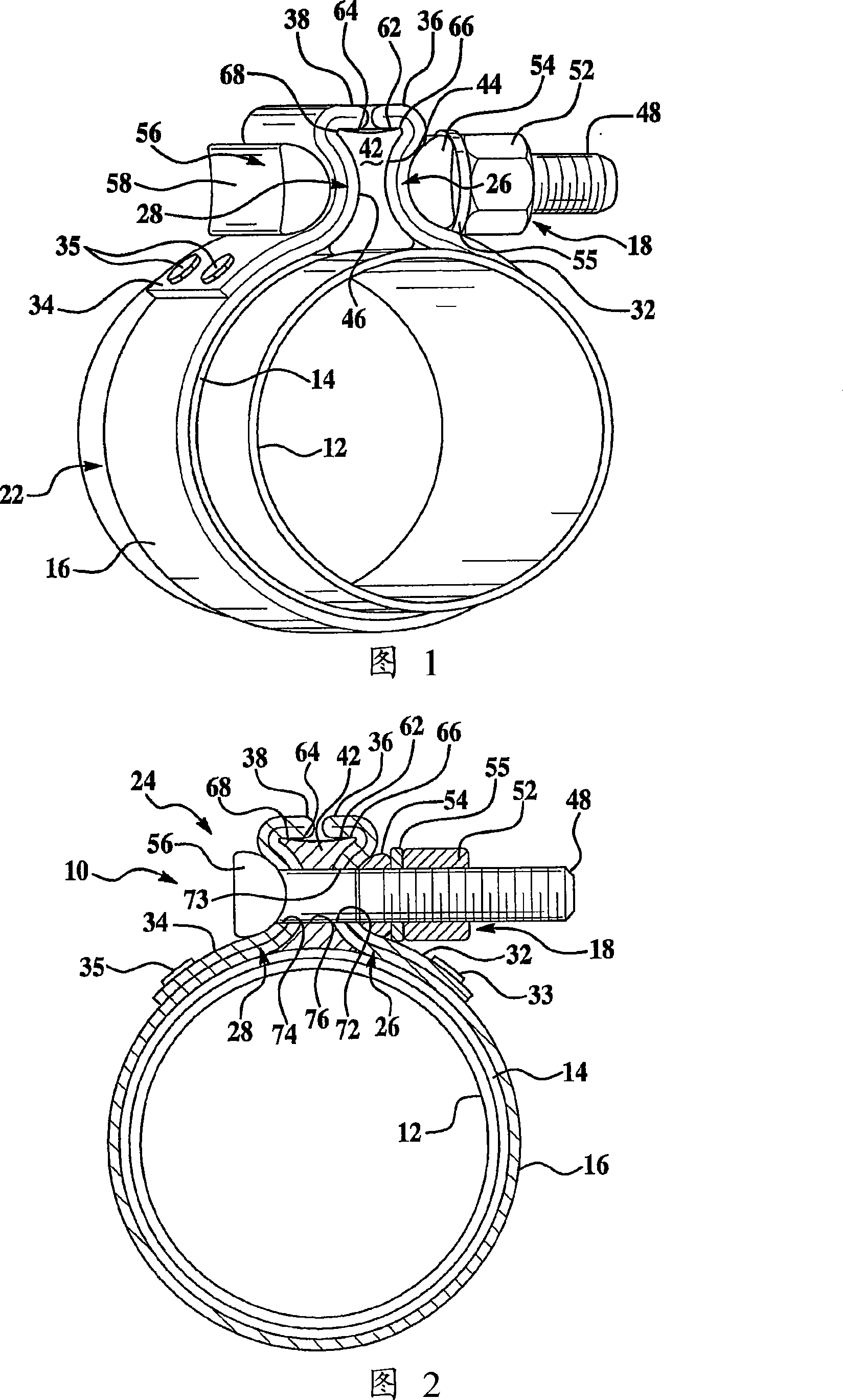

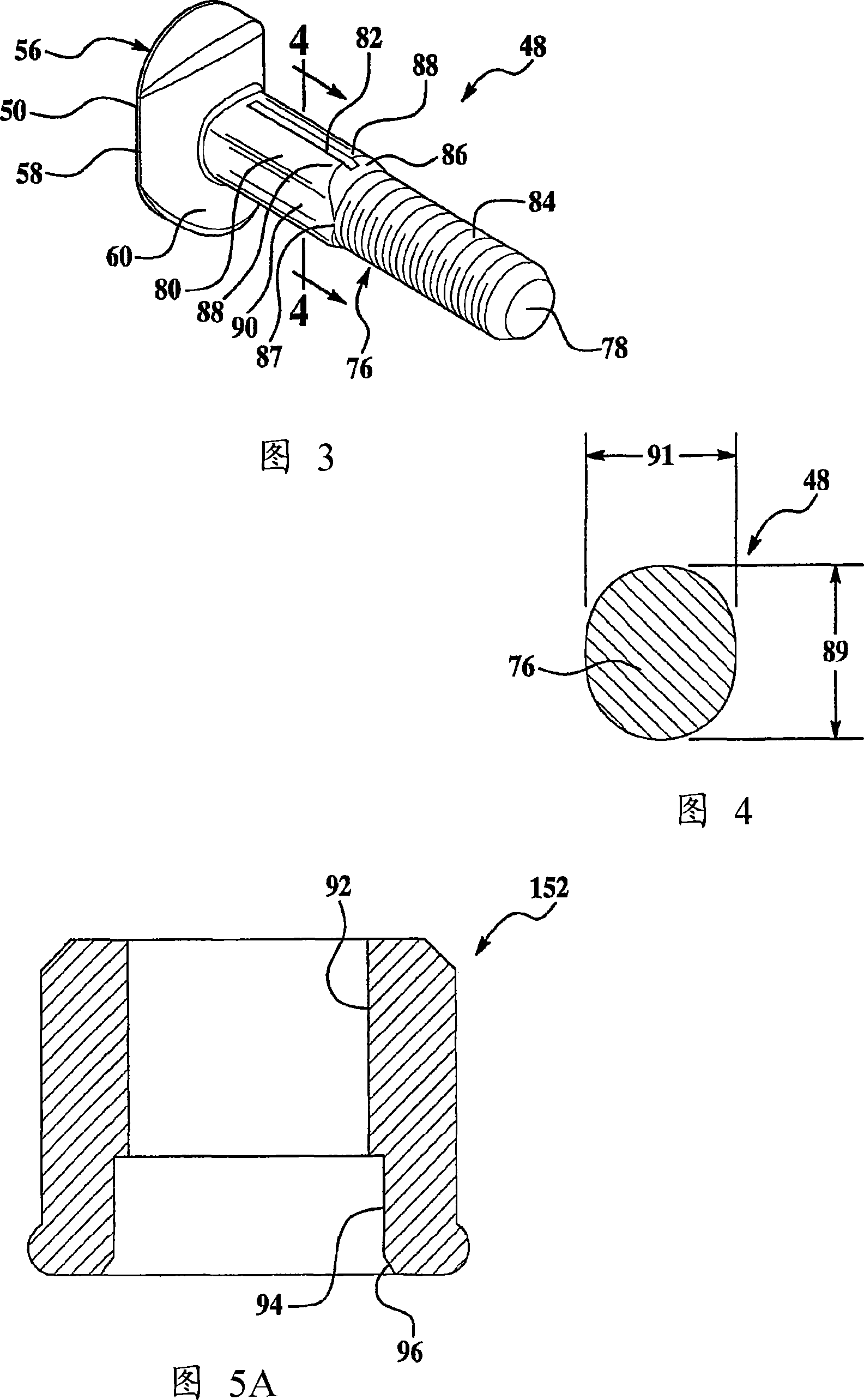

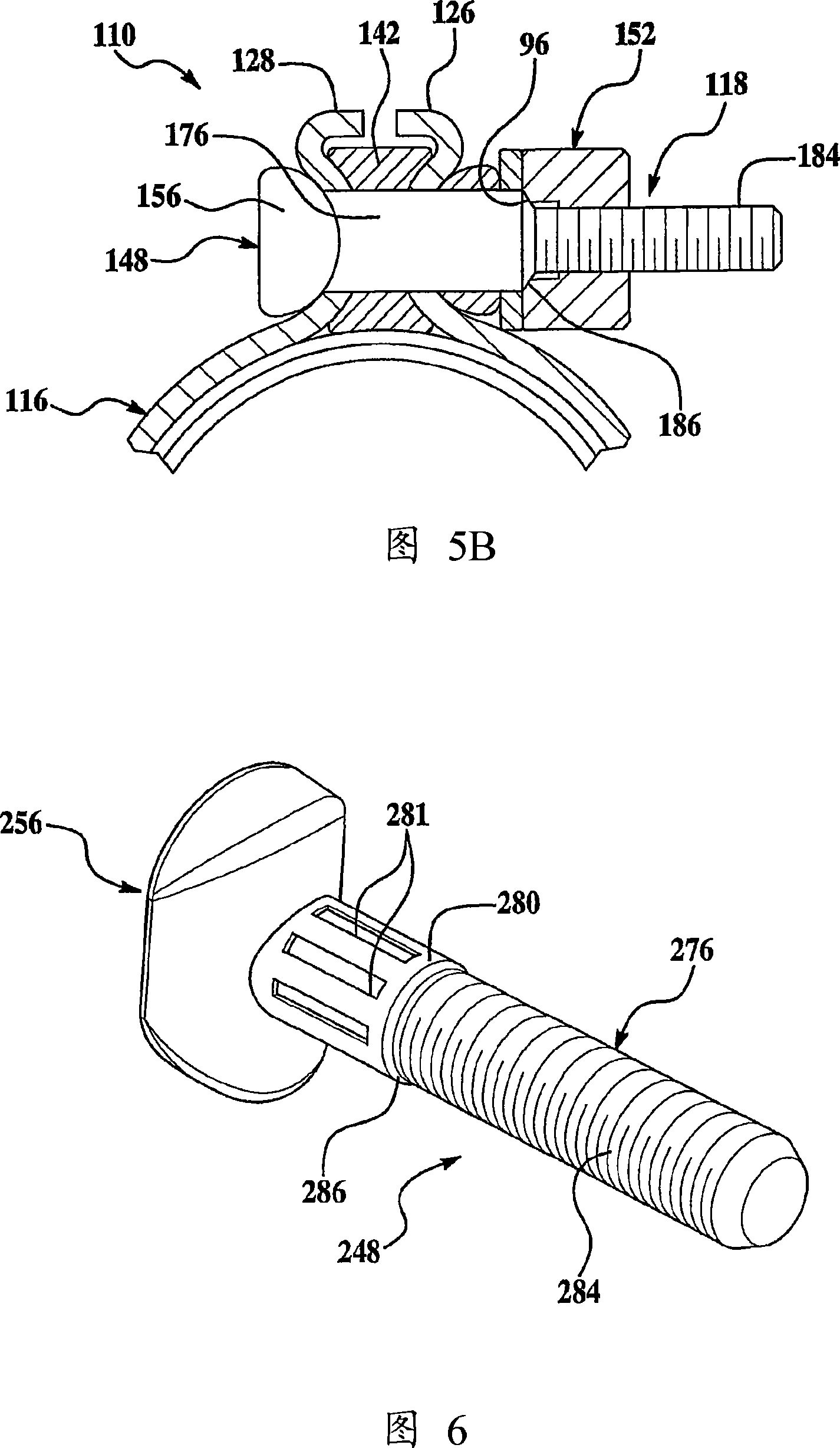

[0024] Two exemplary embodiments of a pipe clamp according to the invention, which are particularly suitable for joining together pipe ends in an automobile exhaust system to form a pipe joint, will be described below with reference to the accompanying drawings. In exhaust system applications, the pipe collar is preferably made of steel. In an exemplary embodiment, the present invention is implemented as a ferrule with a single bolt, the tightening member of which is disclosed in US Patent No. 4,629,226 to Cassel et al. The present invention can also be implemented as a tightening member with two bolts as disclosed in US Patent No. 4,813,270 to Cassel or US Patent No. 6,758,501 to Amedure et al. In the following description, it will be seen that the invention is useful in many different applications, and can be practiced in other embodiments. For example, the present invention is applicable not only to pipe collars for telescoping overlapping pipes, but also to pipe couplings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com