Sizing wear resistant instrument

The technology of sizing and grinding head is applied in the field of sizing wear-resisting instrument, which can solve the problem of difficulty in truly expressing friction load, and achieve the effect of simple and easy operation, suitable for popularization and application, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with embodiment and accompanying drawing thereof, but the present invention is not limited by embodiment:

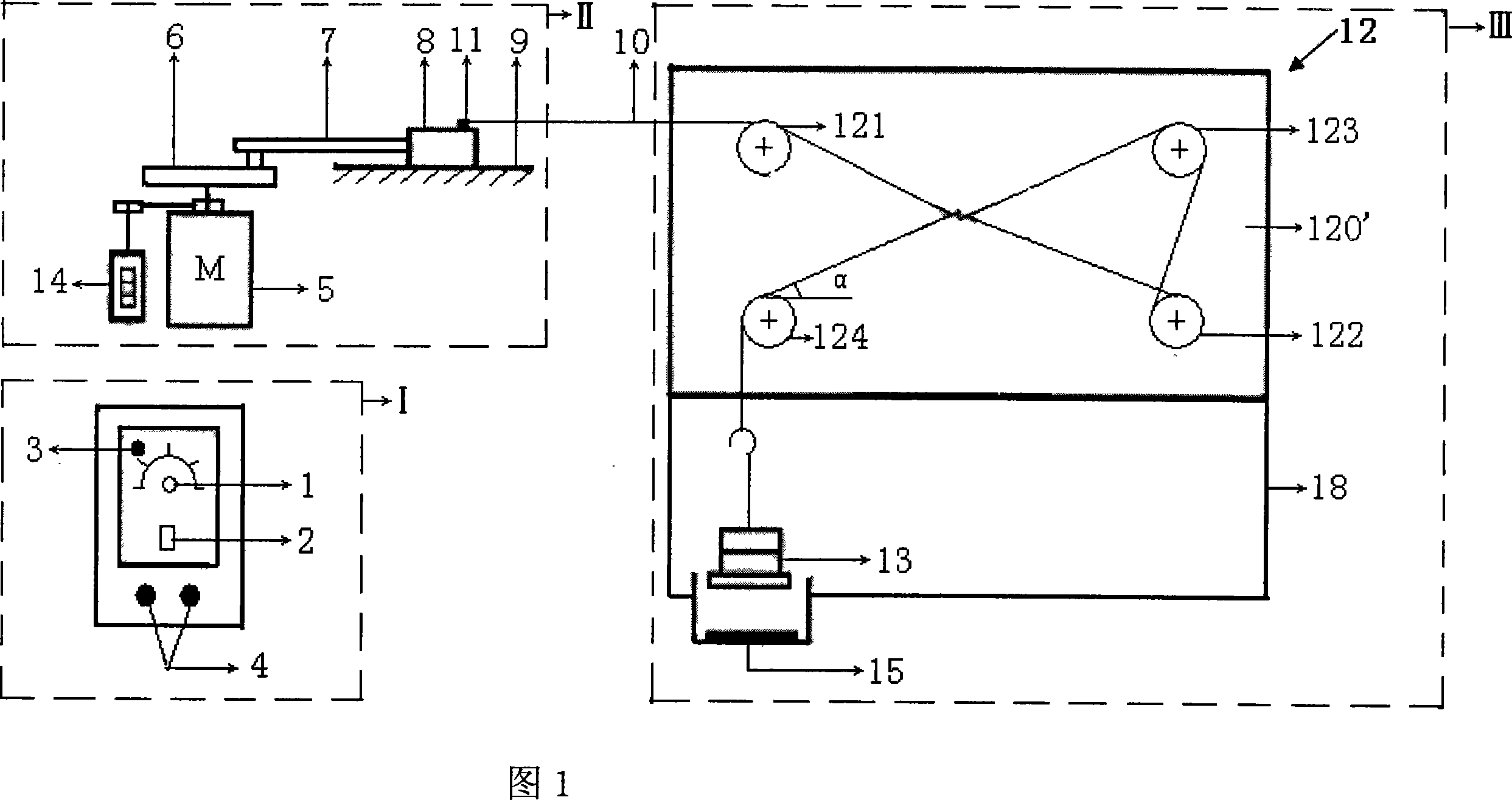

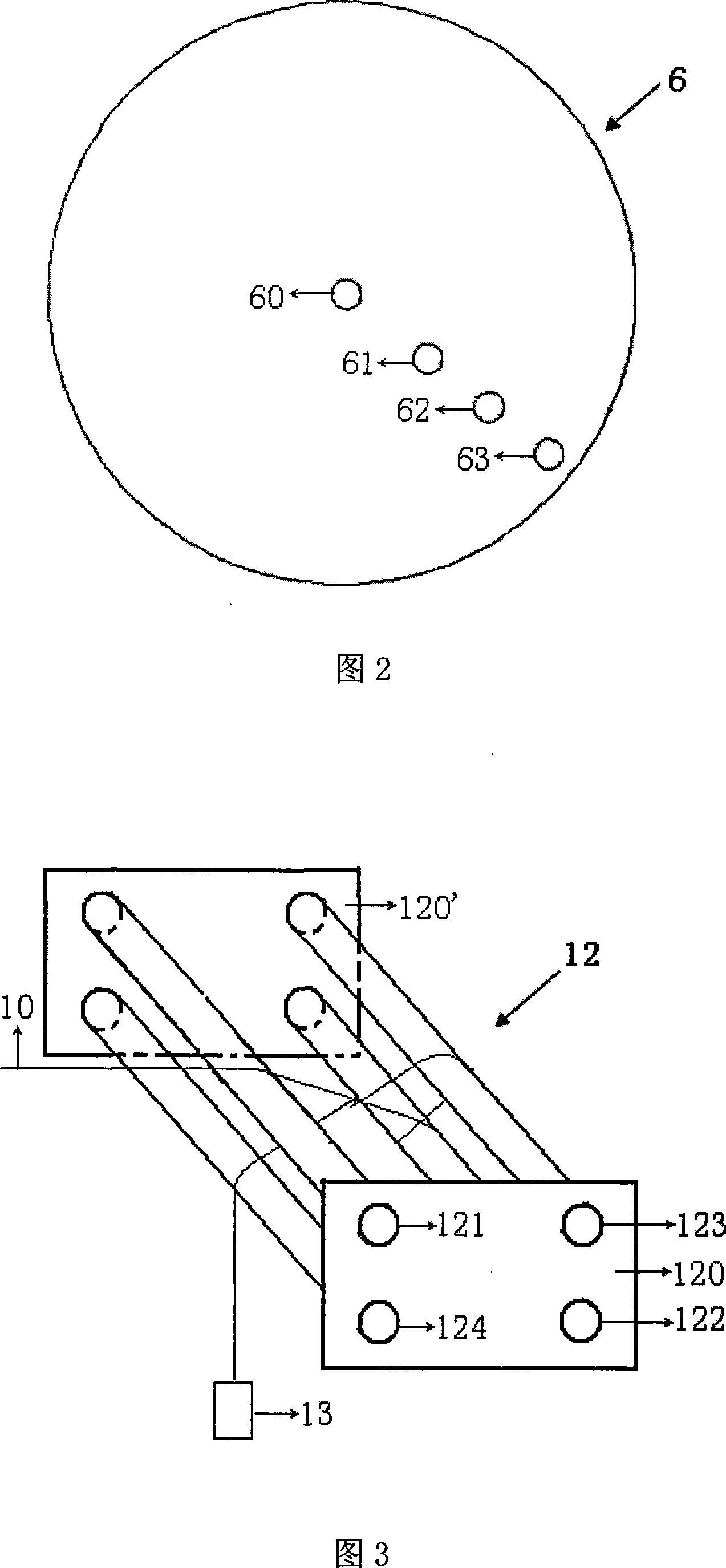

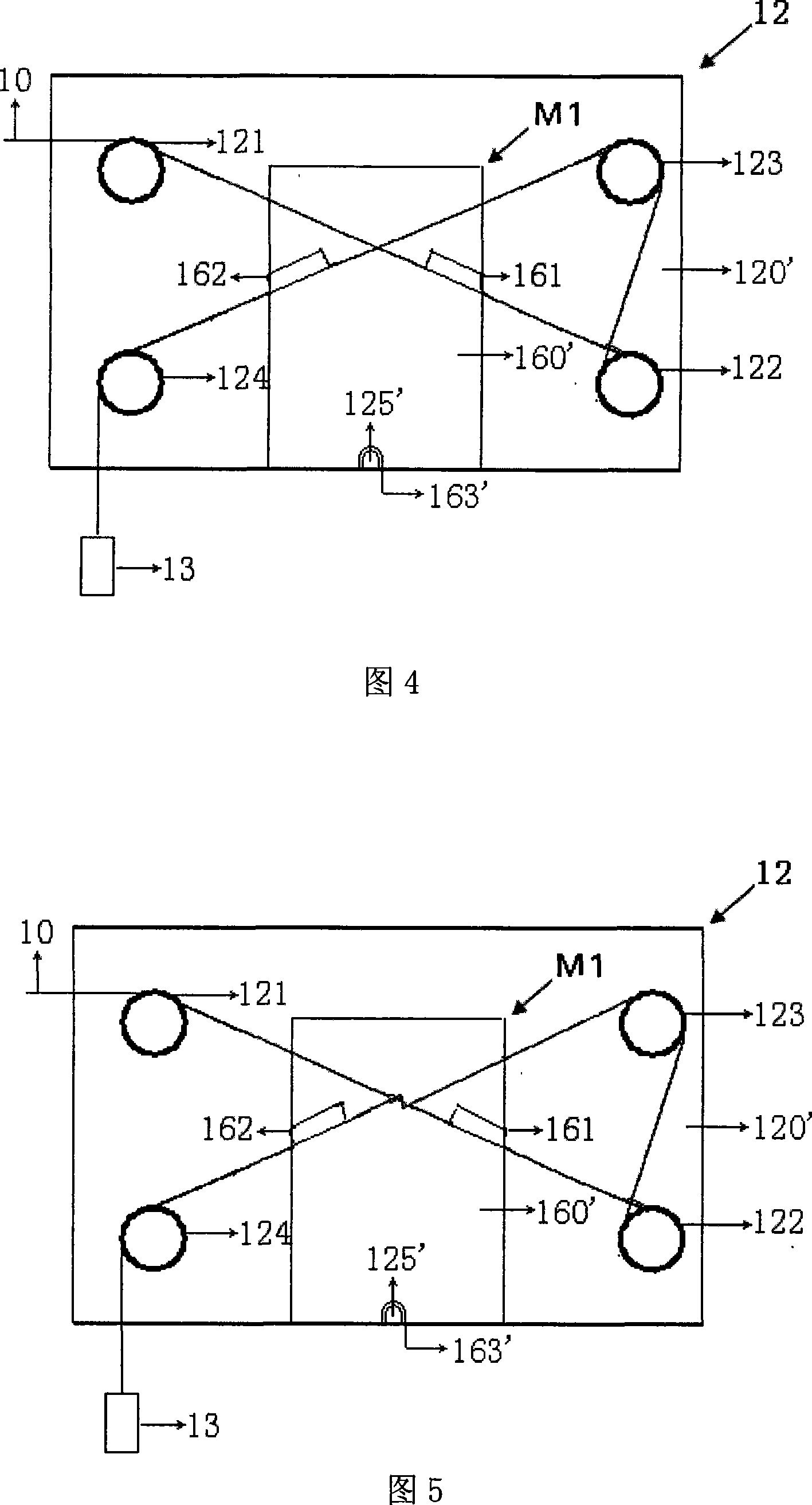

[0018] The sizing wear-resistant instrument of the present invention (hereinafter referred to as the wear-resistant instrument, referring to Fig. 1 ) mainly includes three parts: control, transmission and detection, the control part includes a governor 1, and the transmission part includes a speed-regulating motor 5 and the crank-link slider mechanism composed of crank 6, connecting rod 7 and slider 8, the detection part includes a yarn guide frame 12, and it is characterized in that the crank 6 of the crank-link slider mechanism is a disc configuration, its central hole 60 is fixedly connected to the output shaft of the speed-regulating motor 5, and there are 1-5 equal-diameter connecting holes that can be hinged with the connecting rod 7 along its radial direction; the guide of the detection part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com