Railroad micro-magnetism flaw detector and its defectoscopy

A flaw detector, railway technology, applied in the direction of material magnetic variables, etc., can solve the problems of complex operation (requires 6 people to operate at the same time, the detection is not intelligent, and the resolution of axial defects is low, etc. The effect of stable factor and high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

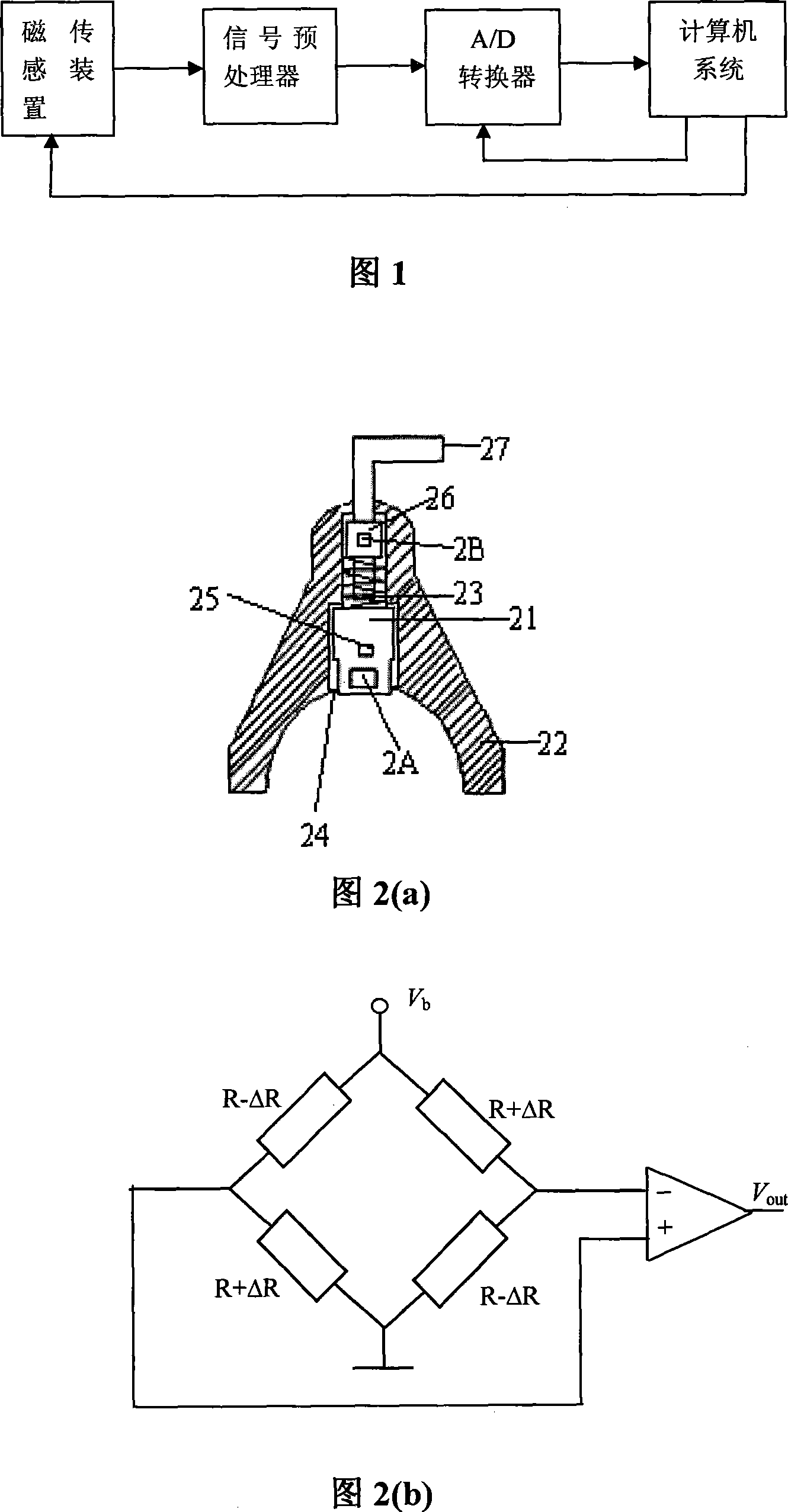

[0030] FIG. 1 is a schematic block diagram of a railway micromagnetic flaw detector of the present invention, which includes a magnetic sensor device 1 , a signal preprocessor 2 , an A / D converter 3 , and a computer system 4 . The magnetic sensor device 1 scans along the surface of the workpiece to obtain the micro-magnetic signal of defect leakage of the inspected workpiece, and converts it into an electrical signal and sends it to the signal preprocessor 2; the signal preprocessor 2 amplifies, filters, and purifies the signal, and converts the signal The signal is sent to the A / D converter 3; the A / D converter converts the signal into a digital signal and sends it to the computer system 4. The computer system 4 controls the work of the above-mentioned parts, and at the same time performs digital filtering, signal analysis, defect feature extraction, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com