A printer

A technology for printing machines and printing cylinders, applied in printing machines, printing, rotary printing machines, etc., can solve problems such as difficult cleaning of anilox rollers, and achieve the effect of simplifying the process of disassembling ink rollers and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

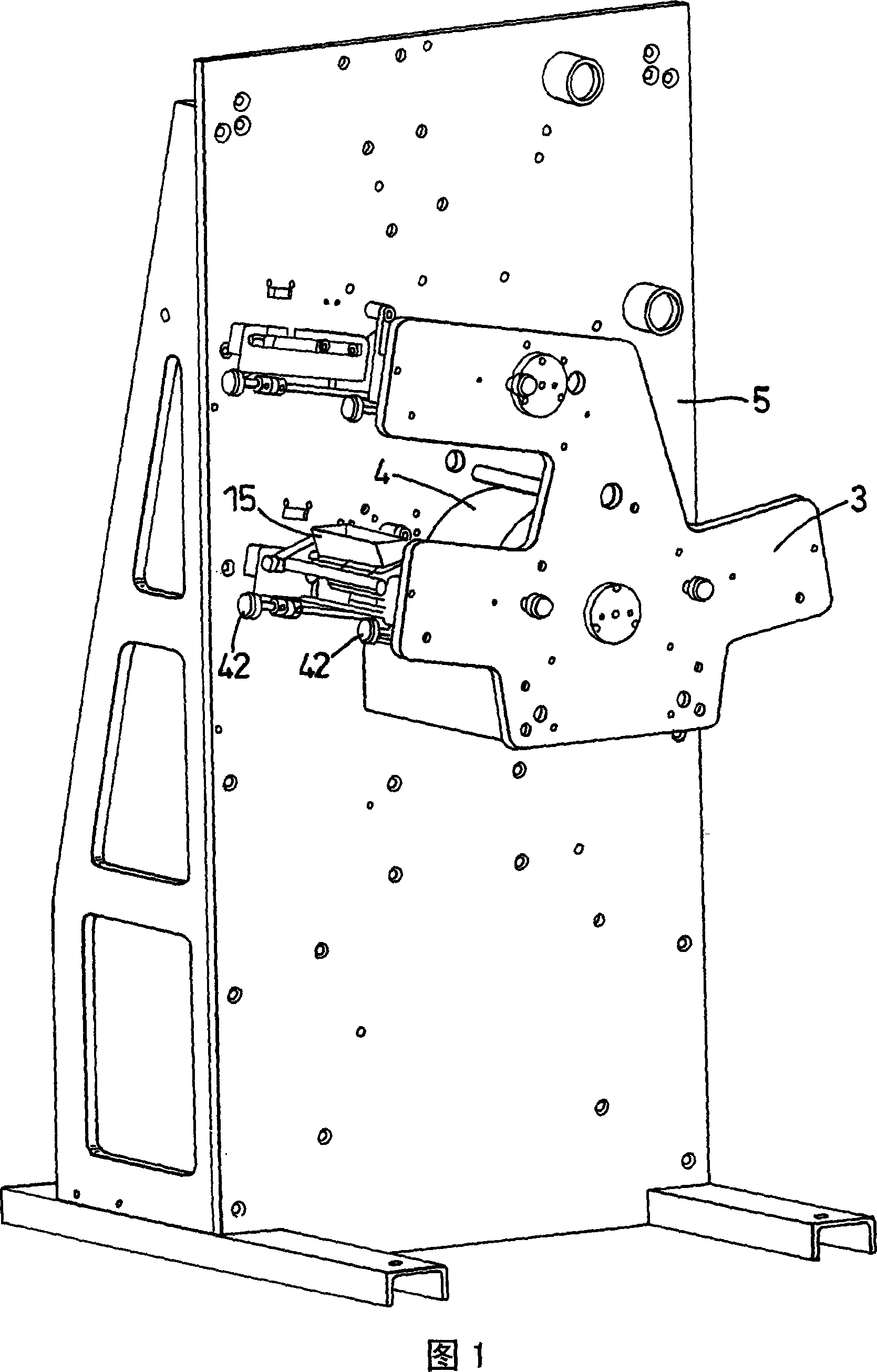

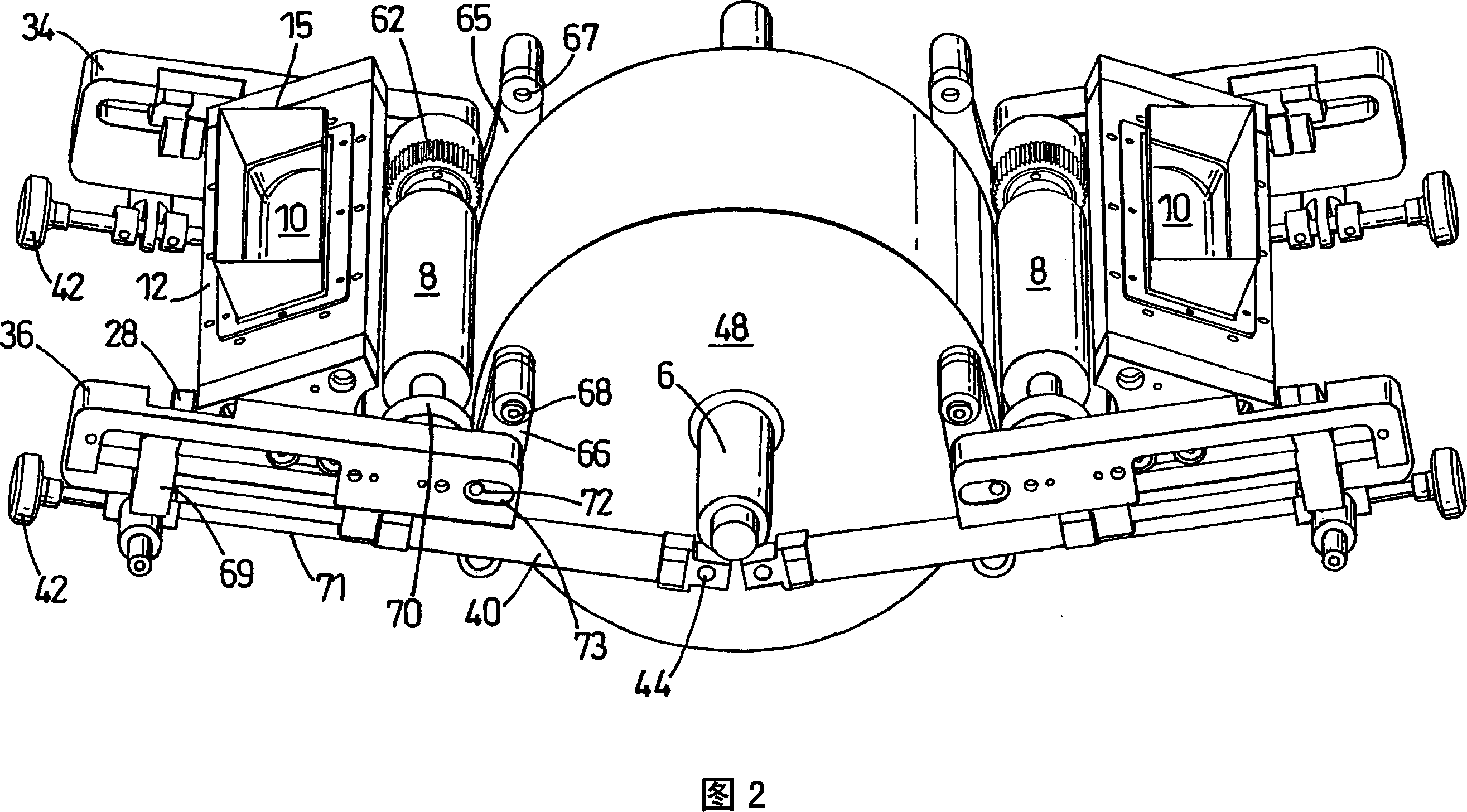

[0054] Referring to the drawings, initially to FIGS. 1 and 2 , an embodiment of a printing machine according to the invention is indicated generally at 2 . The printing press 2 is particularly suitable for printing images in text or other graphic form on continuous strips of textile material. A continuous strip of material to be printed is fed onto a central drum and, once printed, is cut to form individual labels for attachment to garments. The label will typically indicate the washing instructions and material composition of the garment to which it is attached.

[0055] The printing press comprises a front plate 3 and a rear plate 5 .

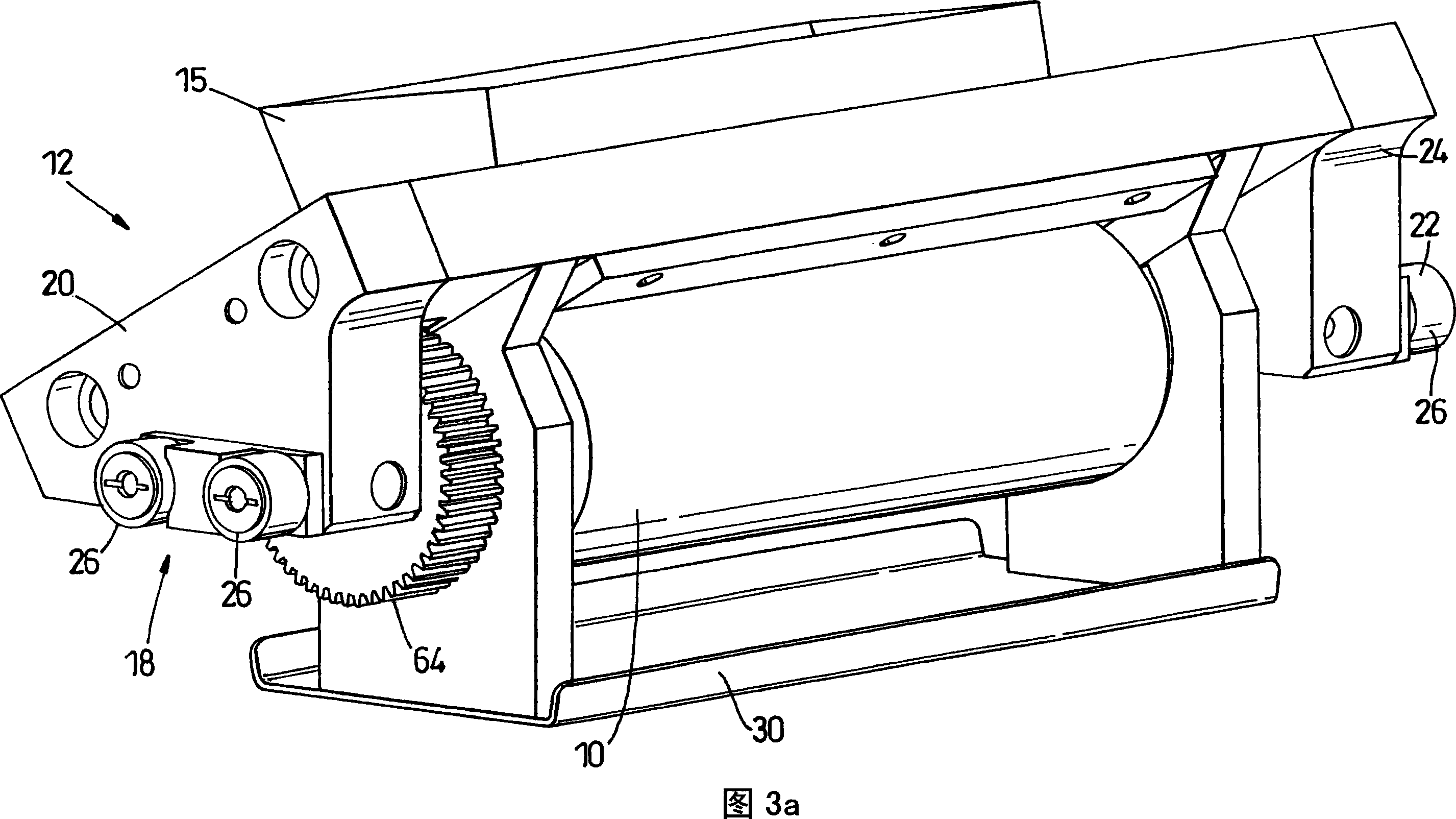

[0056] The printing press comprises a central drum 4 rotatable about a central axis 6 and two printing cylinders 8 . An anilox roller 10 is associated with each printing cylinder 8 . Each print cylinder transfers an image of a specific color onto a strip of material. In this example, the printing press 2 comprises two printing cylinders 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com