Assembled ball goal middle bottom beam and column mounting structure

An installation structure and assembled technology, applied in the direction of ball games, connecting components, sports accessories, etc., can solve the problems of poor stability and troublesome positioning of the goal, and achieve the effect of convenient installation and positioning and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

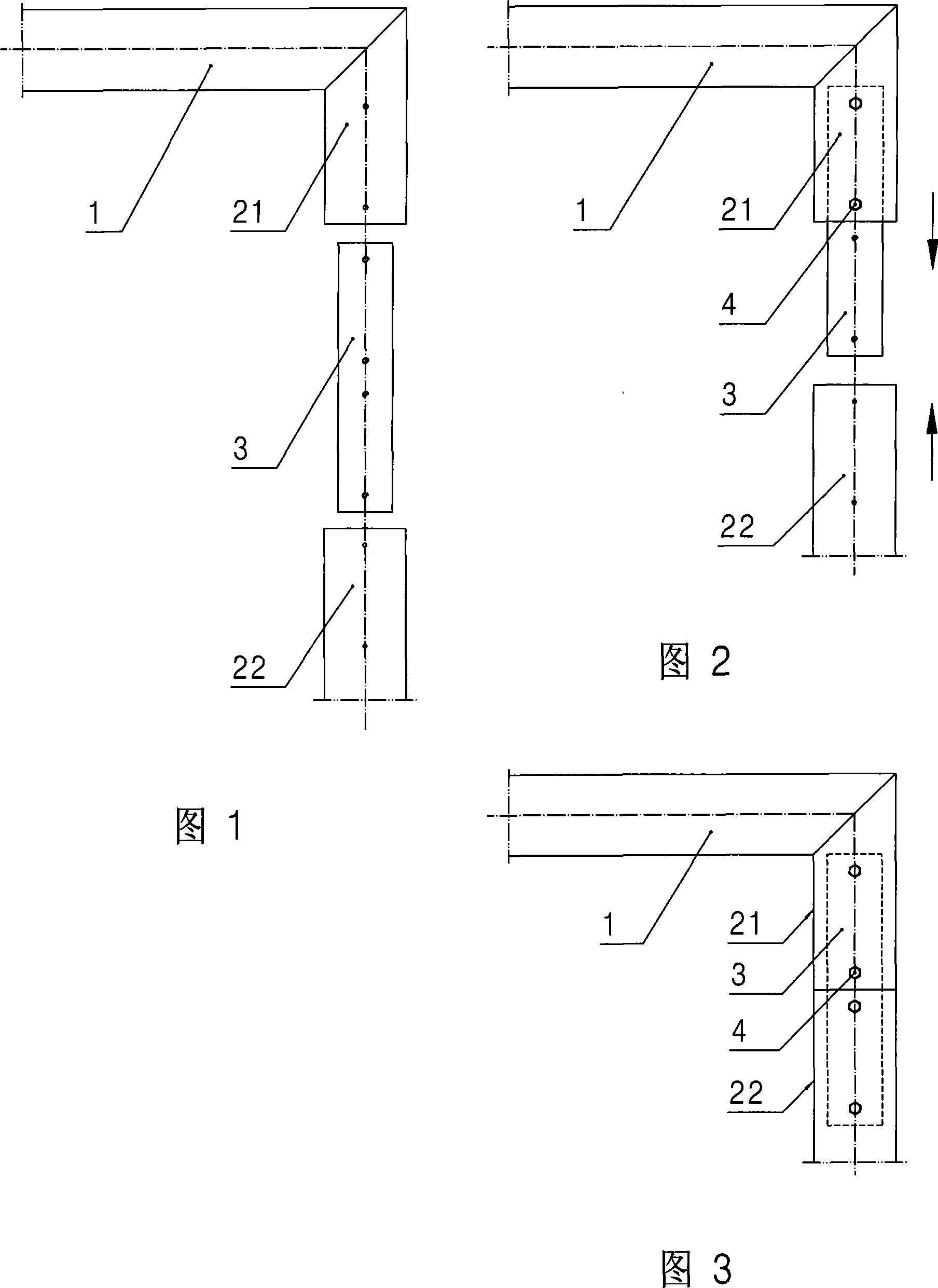

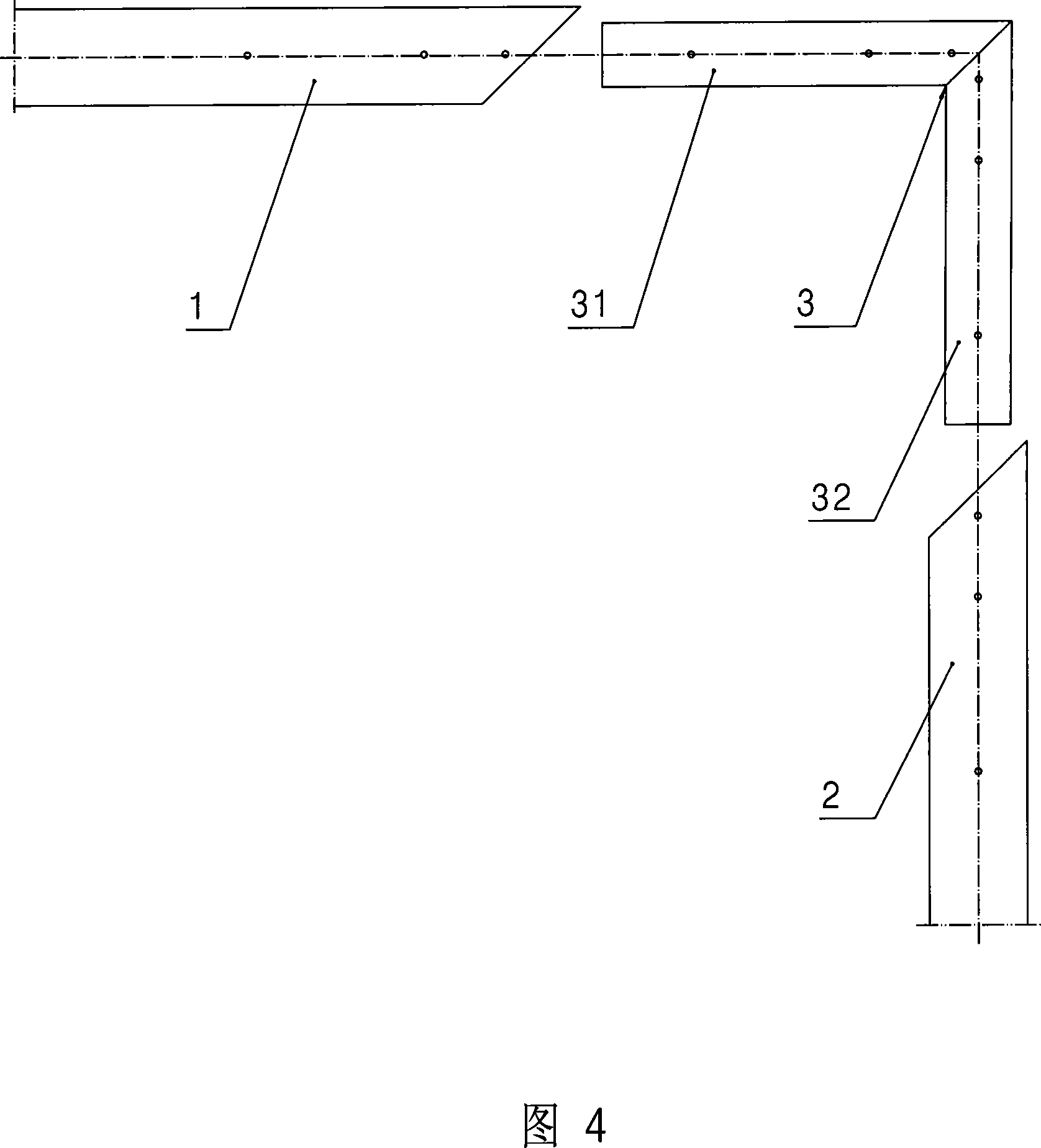

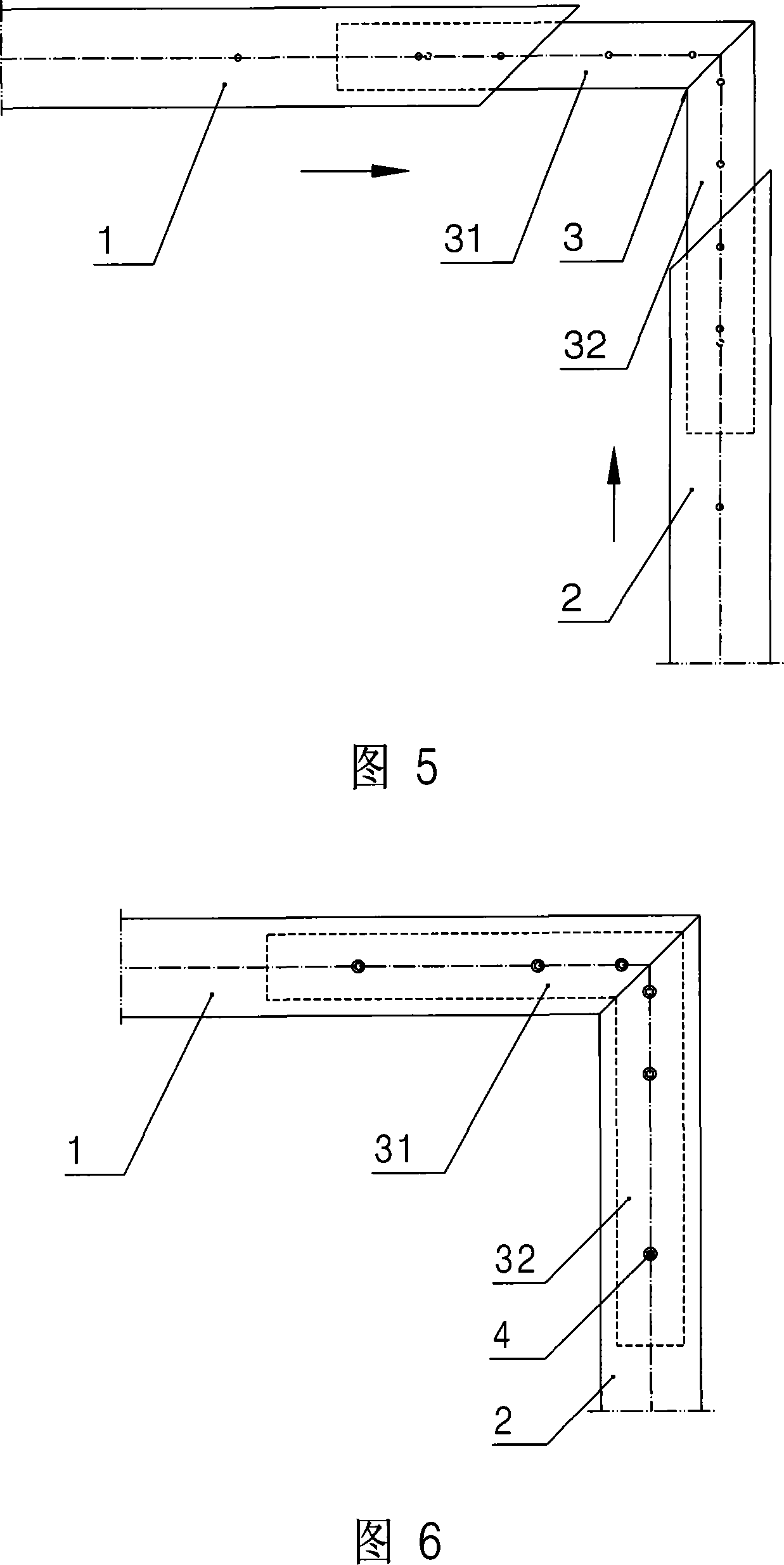

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] As shown in Figure 4, the installation structure of the crossbeam and the column in the assembled goal of the present invention includes: the corner connector 3, the corner connector 3 is composed of a horizontal plug-in 31 and a vertical plug-in 32 perpendicular to each other, and the horizontal plug-in 31 is embedded Set in the connection cavity at the end of the beam 1 and fixed by bolts 4 , the vertical insert 32 is embedded in the connection cavity on the top of the column 2 and fixed by bolts 4 . In this embodiment, both end faces of the beam 1 and the end face of the top end of the column 2 are inclined at an angle of 45°, so that the beam 1 and the column 2 can be completely matched after assembly, and the corner connector 3 is completely covered inside.

[0020] When assembling the beam 1 and the column 2 according to the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com