An elevator landing door positioning device

A door positioning and elevator floor technology, which is applied in the field of elevator landing door positioning devices, can solve the problems of long time-consuming positioning and installation, labor cost, and low assembly accuracy, and achieve the effects of improving installation efficiency, reducing labor costs, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

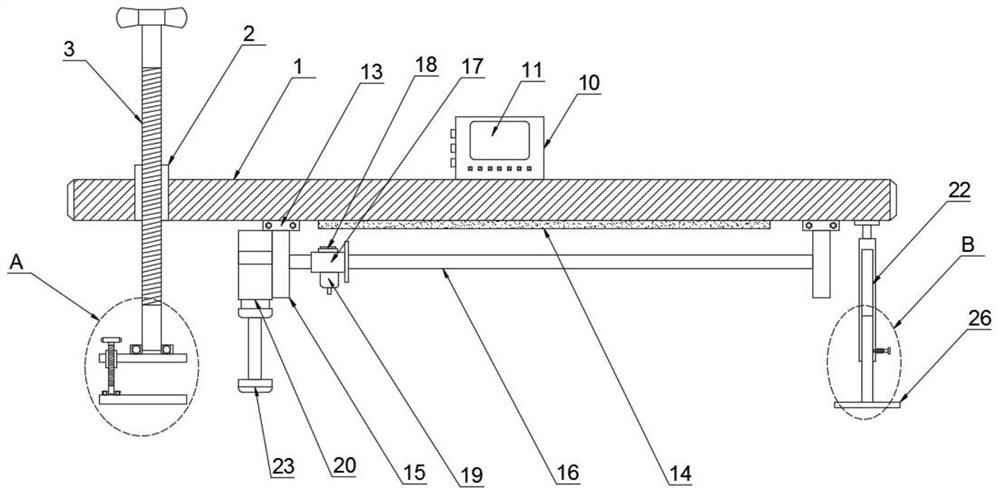

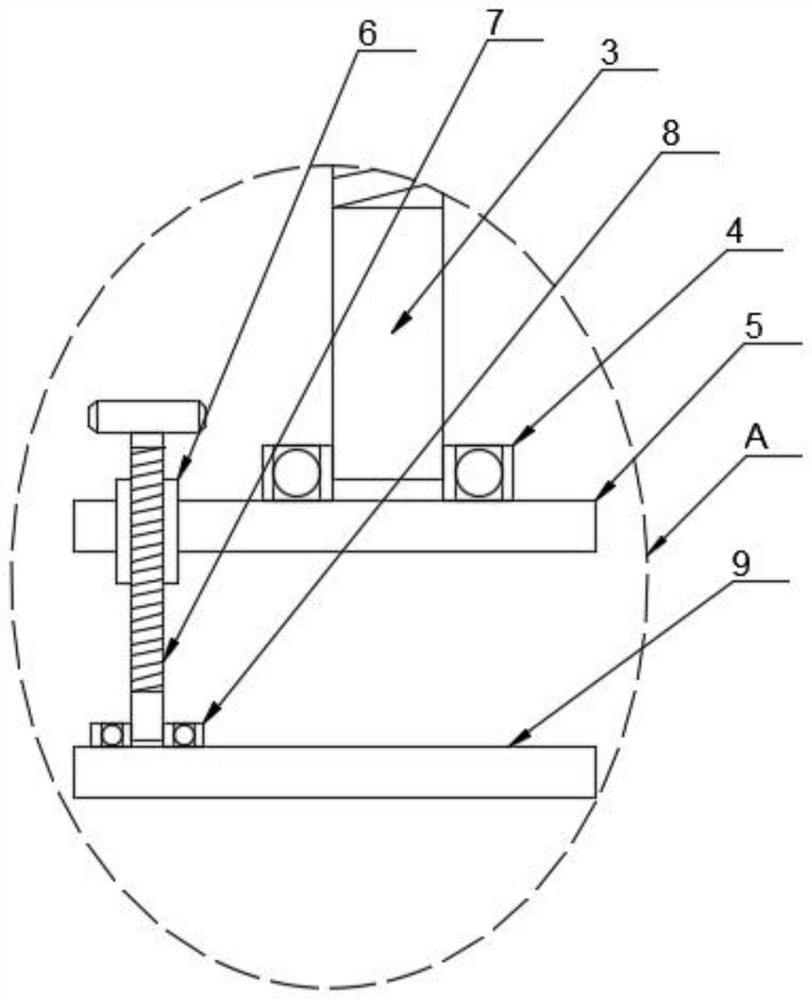

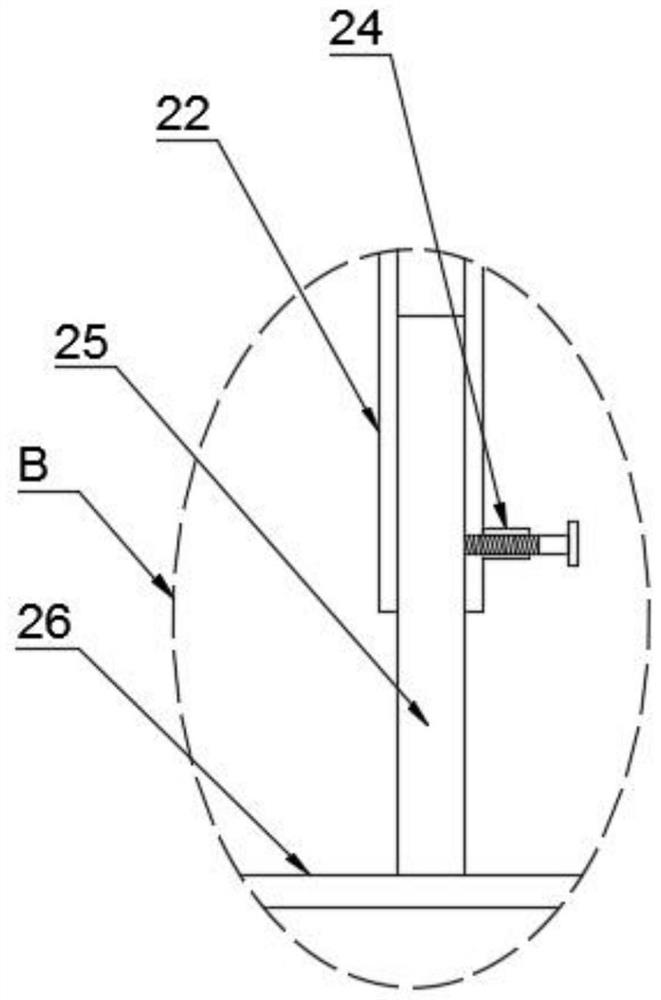

[0023]Such asFigure 1-4An elevator landing door positioning device shown includes a worktable 1 on which a first threaded tube 2 is provided, and a first threaded rod 3 penetrates through the first threaded tube 2, so The bottom end of the first threaded rod 3 is provided with a first bearing 4, the bottom of the first bearing 4 is provided with a first splint 5, and a second threaded tube 6 penetrates through the first splint 5, and the second thread A second threaded rod 7 penetrates through the tube 6, a second bearing 8 is provided at the bottom end of the second threaded rod 7, a second clamping plate 9 is provided at the bottom of the second bearing 8, and the worktable 1 is provided There is a control box 10, the control box 10 is provided with a display screen 11, the control box 10 is provided with a microprocessor 12 inside, and the bottom of the workbench 1 is provided with a mounting block 13, the number of the mounting block 13 The two mounting blocks 13 are provided wi...

Embodiment 2

[0026]Such asFigure 1-4An elevator landing door positioning device shown includes a worktable 1 on which a first threaded tube 2 is provided, and a first threaded rod 3 penetrates through the first threaded tube 2, so The bottom end of the first threaded rod 3 is provided with a first bearing 4, the bottom of the first bearing 4 is provided with a first splint 5, and a second threaded tube 6 penetrates through the first splint 5, and the second thread A second threaded rod 7 penetrates through the tube 6, a second bearing 8 is provided at the bottom end of the second threaded rod 7, a second clamping plate 9 is provided at the bottom of the second bearing 8, and the worktable 1 is provided There is a control box 10, the control box 10 is provided with a display screen 11, the control box 10 is provided with a microprocessor 12 inside, and the bottom of the workbench 1 is provided with a mounting block 13, the number of the mounting block 13 The two mounting blocks 13 are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com