High speed railway slab vibration source device

A high-speed railway and track slab technology, which is applied in the direction of ceramic molding machines and manufacturing tools, can solve the problem that the vibrator cannot meet the technical indicators and quantity requirements of high-speed railway track slabs, and achieve convenient and reliable fixation, satisfying vibration compactness, The effect of increasing the vibration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

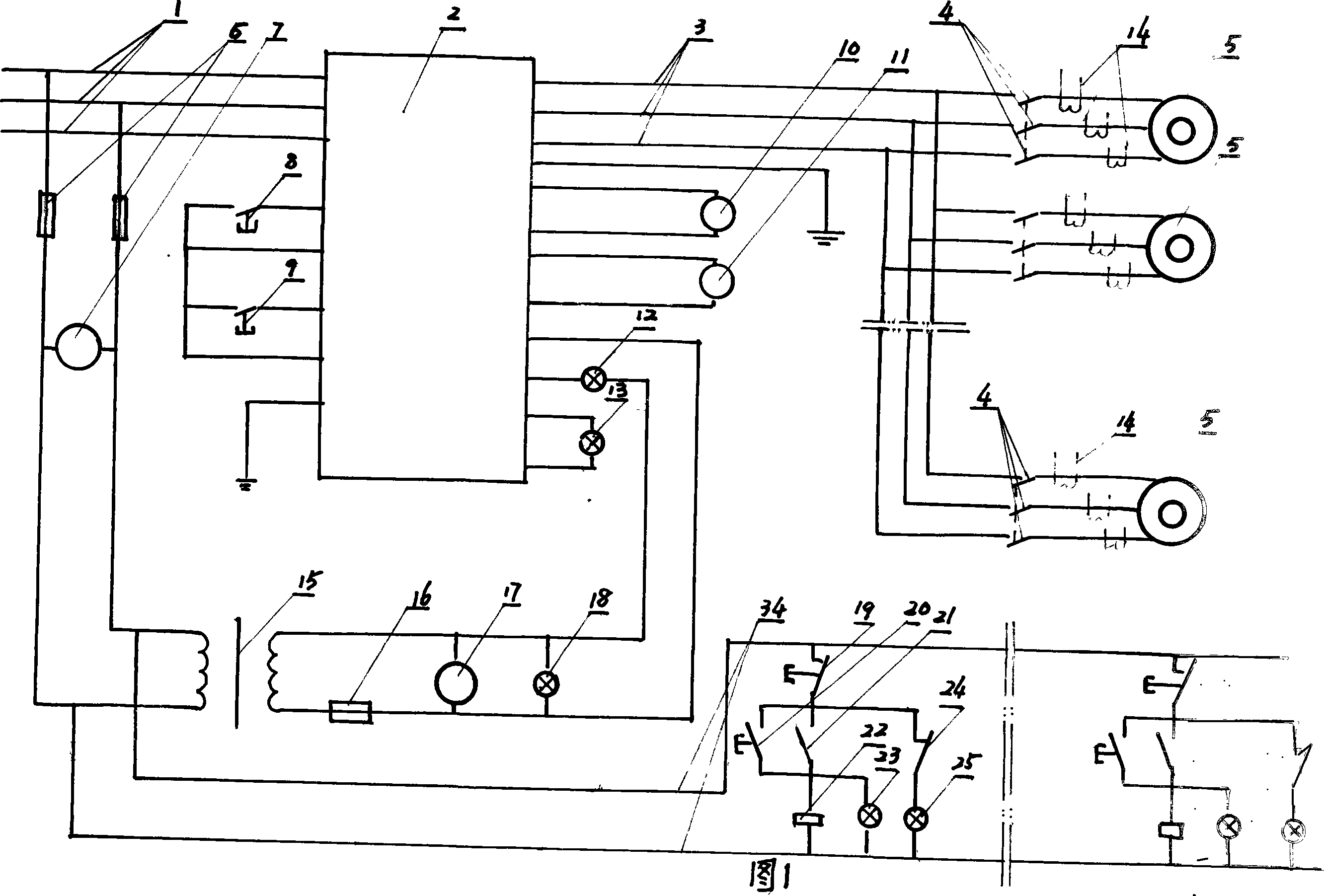

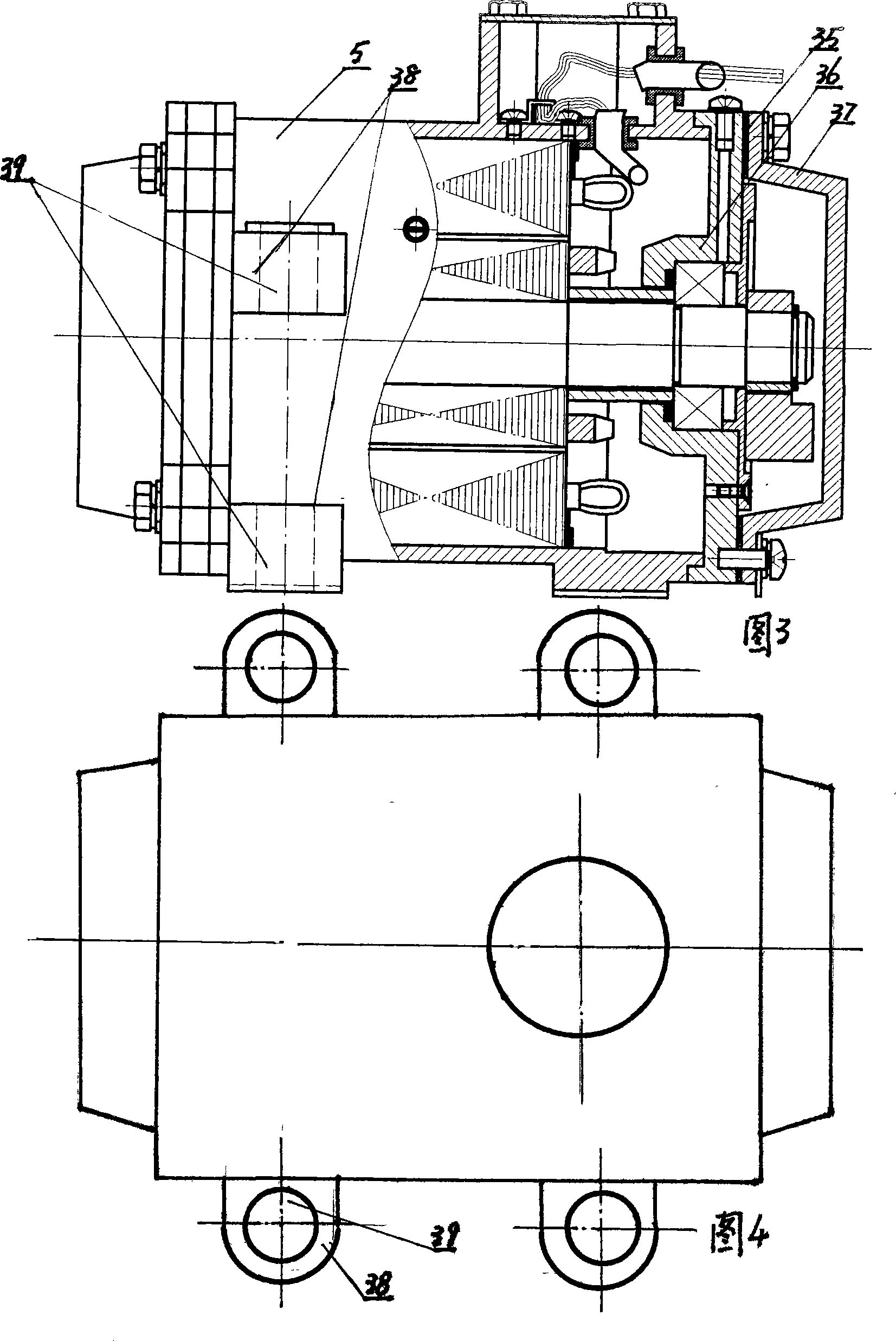

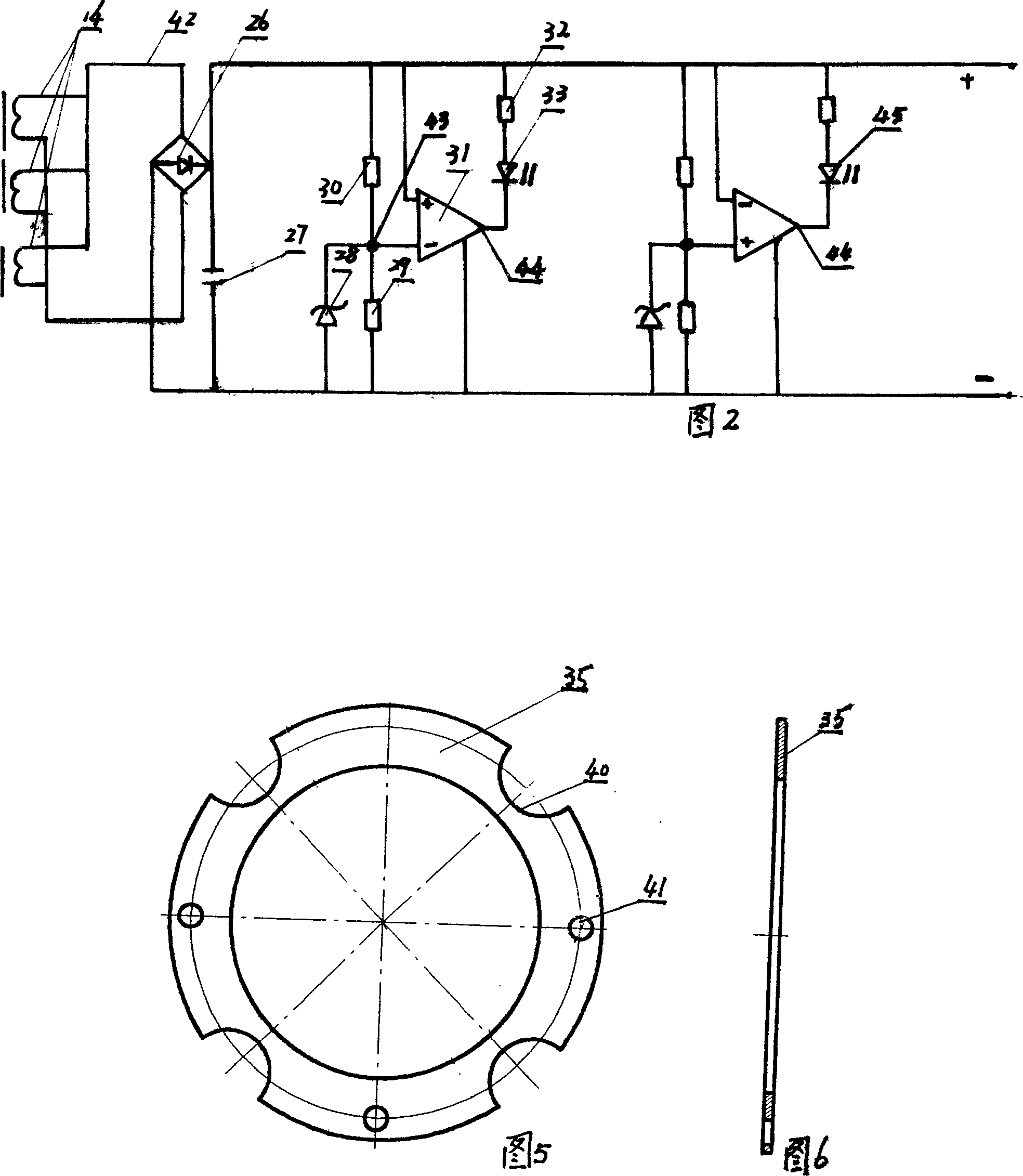

[0007] In conjunction with Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, detail and working condition of the present invention are described in detail. The three-phase power line (1) is connected to the frequency converter (2), and after frequency conversion by the frequency converter, three wires (3) are drawn from the frequency converter (2), and multiple vibrators (5) are connected in parallel on the three wires (3). ), three wires (3) before each vibrator are connected with an AC contactor (4), and an induction coil (14) is set on the three wires (3) before each vibrator (5), and the induction coil There is a fault display control circuit (42) on the top, and a preset connection and preset breaking control circuit (34) is set on the control circuit of the AC contactor (4). The inverter (2) we use is F1000-G0220T3C. At present, most vibrators use a power supply frequency of 50 Hz, and the frequency of the power supply after frequency conversion reaches 150 Hz, thereby in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com