Group control vulcanizing unit

A vulcanizing machine and unit technology, applied to tires, other household appliances, household appliances, etc., can solve the problems of taking up a long time, occupying space on the site, and wasting the cost of vulcanizing machine supporting equipment, so as to reduce the occupied space and cost, and improve The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

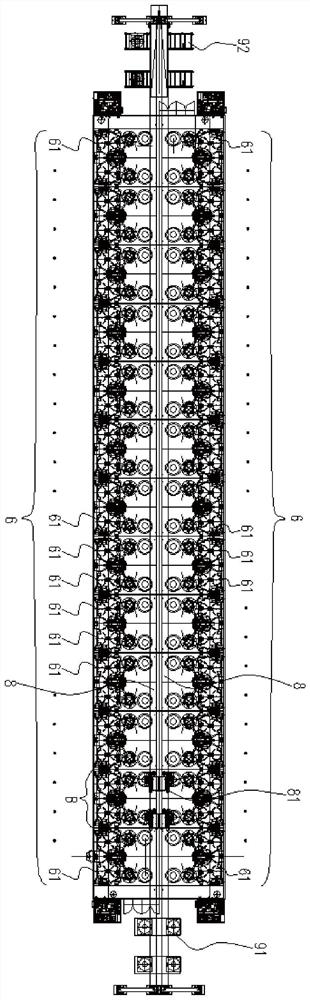

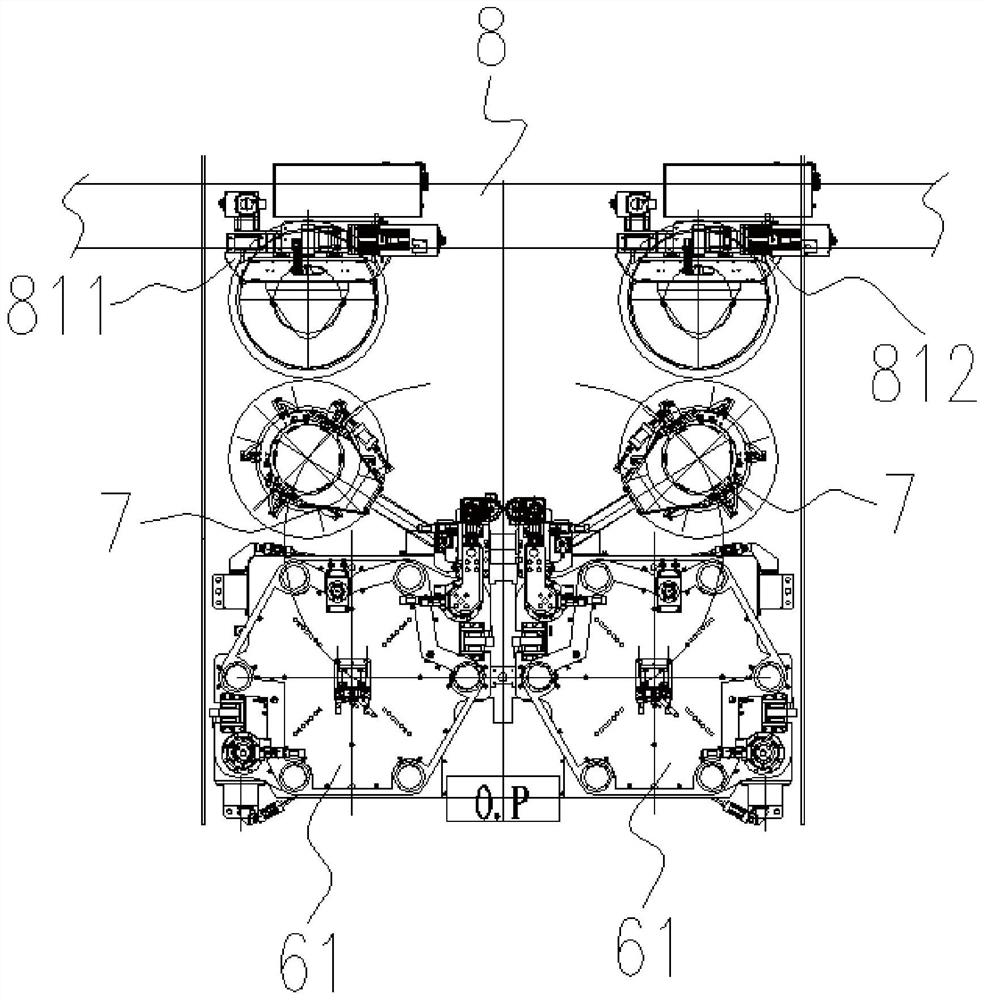

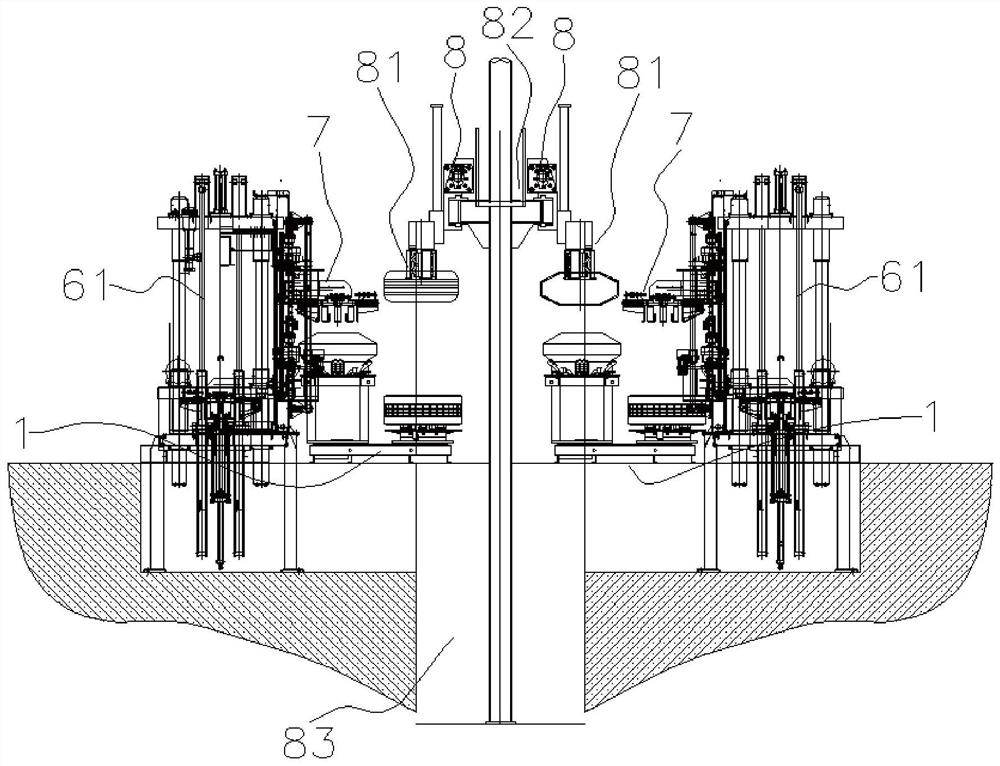

[0045] Such as Figure 1-4 As shown, an embodiment of the present invention is: a group control vulcanization unit, comprising:

[0046] At least one row of vulcanizer single-row combination 6, the vulcanizer single-row combination 6 includes multiple vulcanizers 61 arranged side by side, and each vulcanization position of each vulcanizer is provided with one for putting raw tires into the vulcanization mold and The vulcanizing machine manipulator 7 that takes out the cooked tire from the vulcanizing mold;

[0047] At least one public conveying system 8 is arranged in parallel with the vulcanizing machine single-row combination 6. The public conveying system 8 is provided with a common manipulator 81 shared by all vulcanizing machines in the vulcanizing machine single-row combination. The public manipulator 81 runs along the common conveying system 8 move;

[0048] A plurality of double-station tire storage devices 1, a double-station tire storage device 1 is configured at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com