Imitated natural corner cultural stone and manufacturing method for die thereof

A cultural stone imitating natural technology, applied in the field of building materials manufacturing, can solve the problems of difficulty in achieving consistent surface decoration effects, difficult control of decoration quality, and inconsistent angles of corners, etc., achieve valuable market application prospects, improve visual effects, and ensure decoration quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

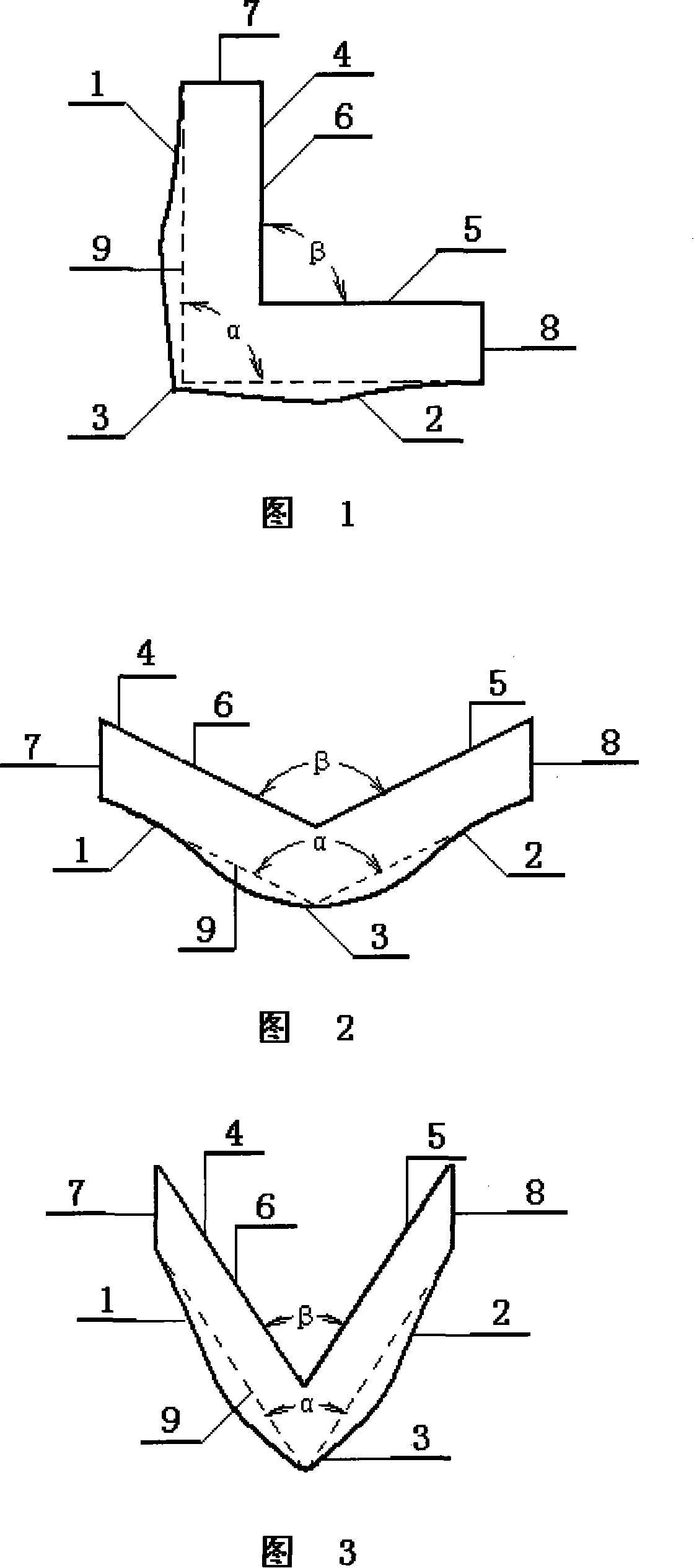

[0015] Embodiment 1 right-angle type

[0016] In Fig. 1, the imitation natural corner cultural stone main body of the present invention is " L " shape, and its basic thickness and width and the wall surface that match use match with the thickness and the width paste assembly of imitation natural cultural stone, by having two mutually forming The α angle, the upper band and the matching wall are made of the outer surface of the imitation natural cultural stone, the outer surface of the decorative surface 1 and 2, the outer bending surface 3, and the two inner side adhesive surfaces 4 and 5 that form a β angle. The inner bending surface 6 and two continuous end surfaces 7 and 8 are formed. Wherein, the α angle and the β angle are both 90°, and the basic plane 9 of the outer bending surface 3 and the inner bending surface 6 are parallel to each other.

Embodiment 2

[0017] Example 2 obtuse angle type

[0018] In Fig. 2, the imitation natural corner culture stone main body of the present invention is " L " shape, and its basic thickness and width and the thickness and the width paste assembly of the imitation natural culture stone of the matching usefulness of the wall are consistent, by having two mutually forming The α angle, the upper band and the matching wall are made of the outer surface of the imitation natural cultural stone, the outer surface of the decorative surface 1 and 2, the outer bending surface 3, and the two inner side adhesive surfaces 4 and 5 that form a β angle. The inner bending surface 6 and two continuous end surfaces 7 and 8 are formed. Wherein, the angle α and the angle β are the same, and both are obtuse angles greater than 90°, and the basic plane 9 of the outer bending surface 3 and the inner bending surface 6 are parallel to each other.

Embodiment 3

[0019] Embodiment 3 acute angle type

[0020] In Fig. 3, the imitation natural corner culture stone main body of the present invention is " L " shape, and its basic thickness and width and the thickness and the width paste assembly of the imitation natural culture stone of the matching usefulness of the wall are consistent, by having two mutually forming The α angle, the upper band and the matching wall are made of the outer surface of the imitation natural cultural stone, the outer surface of the decorative surface 1 and 2, the outer bending surface 3, and the two inner side adhesive surfaces 4 and 5 that form a β angle. The inner bending surface 6 and two continuous end surfaces 7 and 8 are formed. Wherein, the α angle and the β angle are the same, and both are acute angles less than 90°, and the basic plane 9 of the outer bending surface 3 and the inner bending surface 6 are parallel to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com