A hanging buckle type cylinder glass installation structure and using method

A technology for installing structure and glass, applied in building construction, covering/lining, building, etc., can solve the problems of large local stress at the lower end of the glass, poor decorative effect, and cracking of glass veneer, so as to achieve the overall simplicity and convenience of installation. Efficient and fast, avoiding the effect of excessive vertical deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

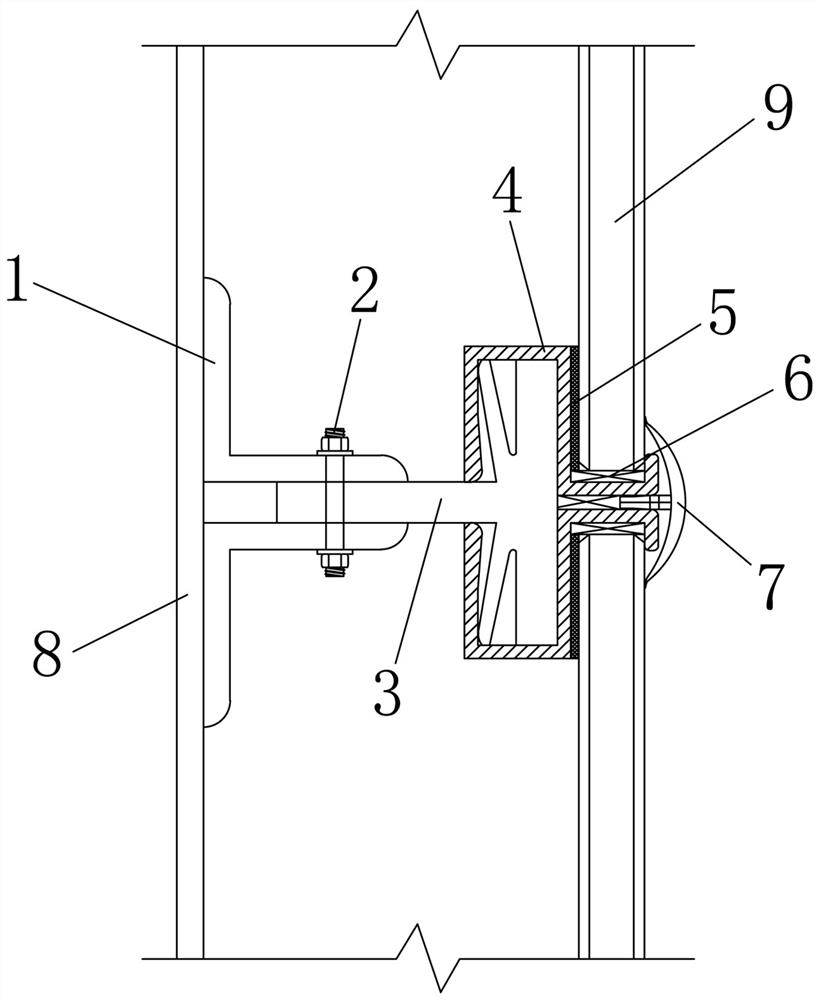

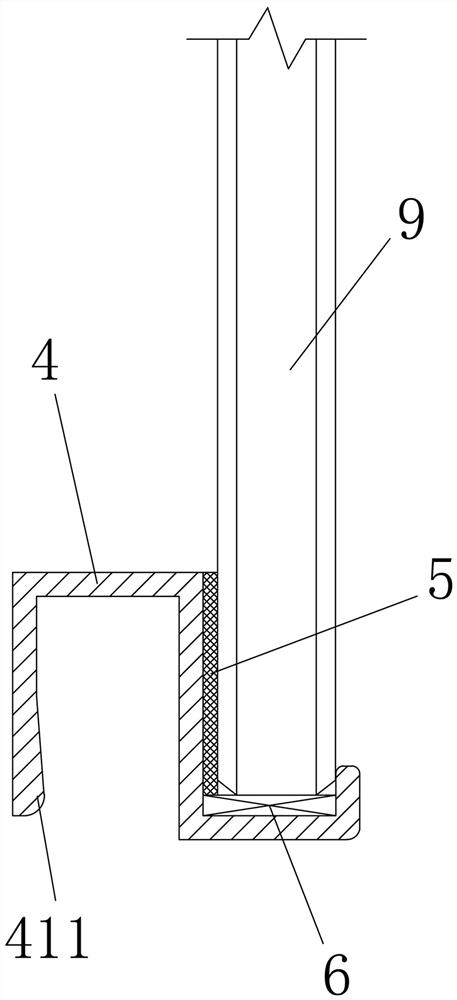

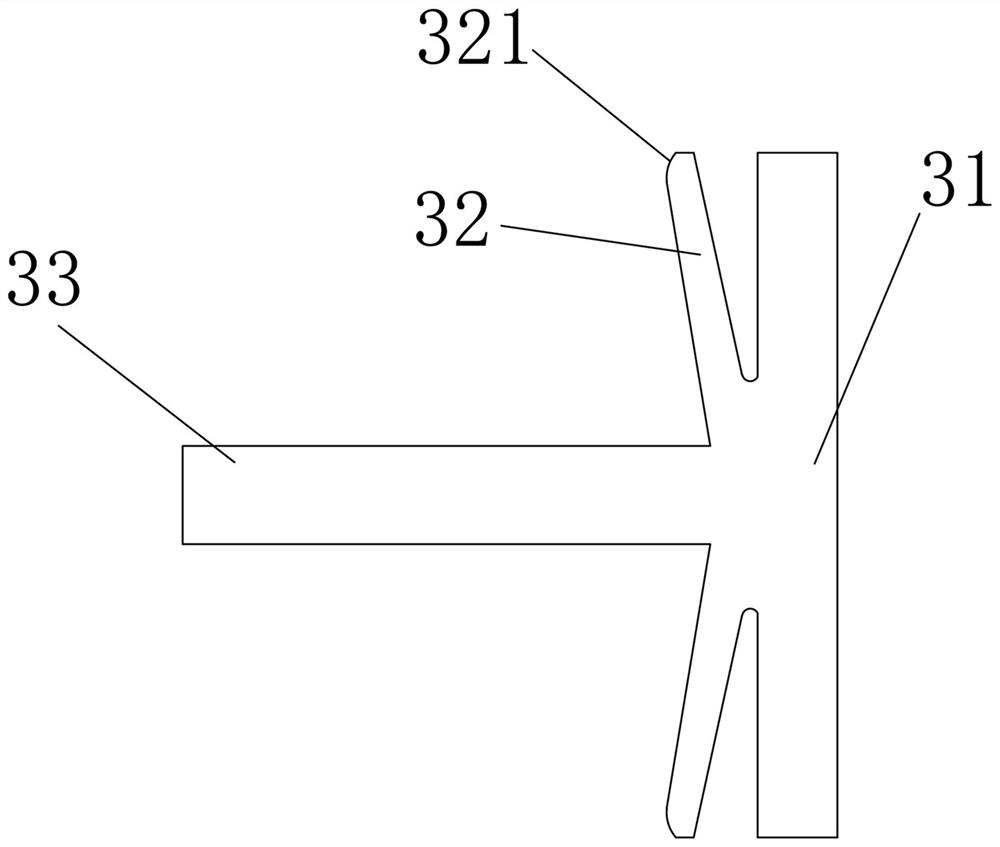

[0042] Embodiment one: if Figures 1 to 8As shown, it is only one of the embodiments of the present invention, a hanging-type cylindrical glass installation structure, including a mounting part 1, a fixing part 2, a hooking part 3, and a hooking groove 4. The mounting part 1 One end is fixed on the installation surface 8, and the other end of the mounting part 1 is affixed to the fixing plate 33 of the hanging part 3 through the fixing part 2. The abutment plate 31, the fixed plate 33 bisects the abutment plate 31, the angle between the abutment plate 31 and the fixed plate 33 is provided with a buckle plate 32, and the buckle plate 32 is opposite to The abutment plate 31 is arranged obliquely, the buckle plate 32 and the abutment plate 31 form a buckle, and the buckle is separately arranged on both sides of the fixed plate 33, and the hooking groove 4 The clamping plate 41, the stopper plate 42, and the connecting plate 43 form a buckling cavity, the buckling member can be b...

Embodiment 2

[0053] Embodiment two, such as Figure 5 As shown, the present invention also provides a method for using a hanging-type cylindrical glass installation structure in all the above-mentioned embodiments, including the following steps:

[0054] S1: Fix the installation parts on the installation surface, and the installation parts are respectively arranged on the four sides of the glass veneer;

[0055] S2: level and fix the hook and the mounting piece through the fixing piece;

[0056] S3: First, buckle the buckle cavity of the hooking groove on the three sides on the buckle of the hitch, reserve one side as a plug-in installation space, set a flexible pad in the clamping groove, two A flexible pad is arranged between the bottom plates of the hooking groove;

[0057] S4: Insert the glass veneer from the reserved side into the clamping grooves on the three sides, and fix it with structural glue; then slide the reserved side mounting groove along the side of the glass veneer , C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com