Combined cooling structure for turbine blade middle-part inclined impact aerating film

A technology of turbine blades and cooling structure, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve problems such as insufficient cooling of blades, and achieve the effects of improving heat exchange, increasing flow speed, and reducing flow resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

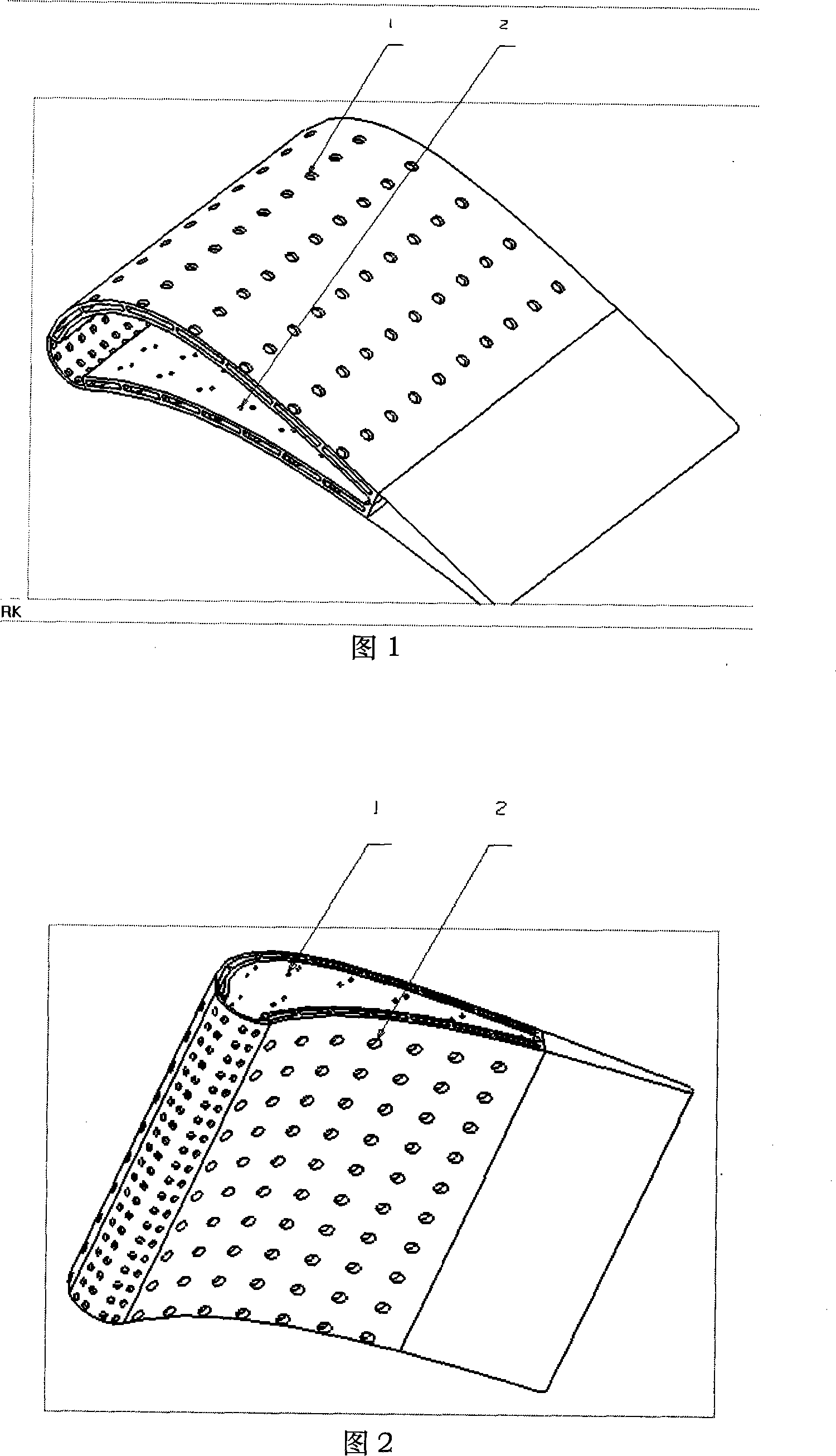

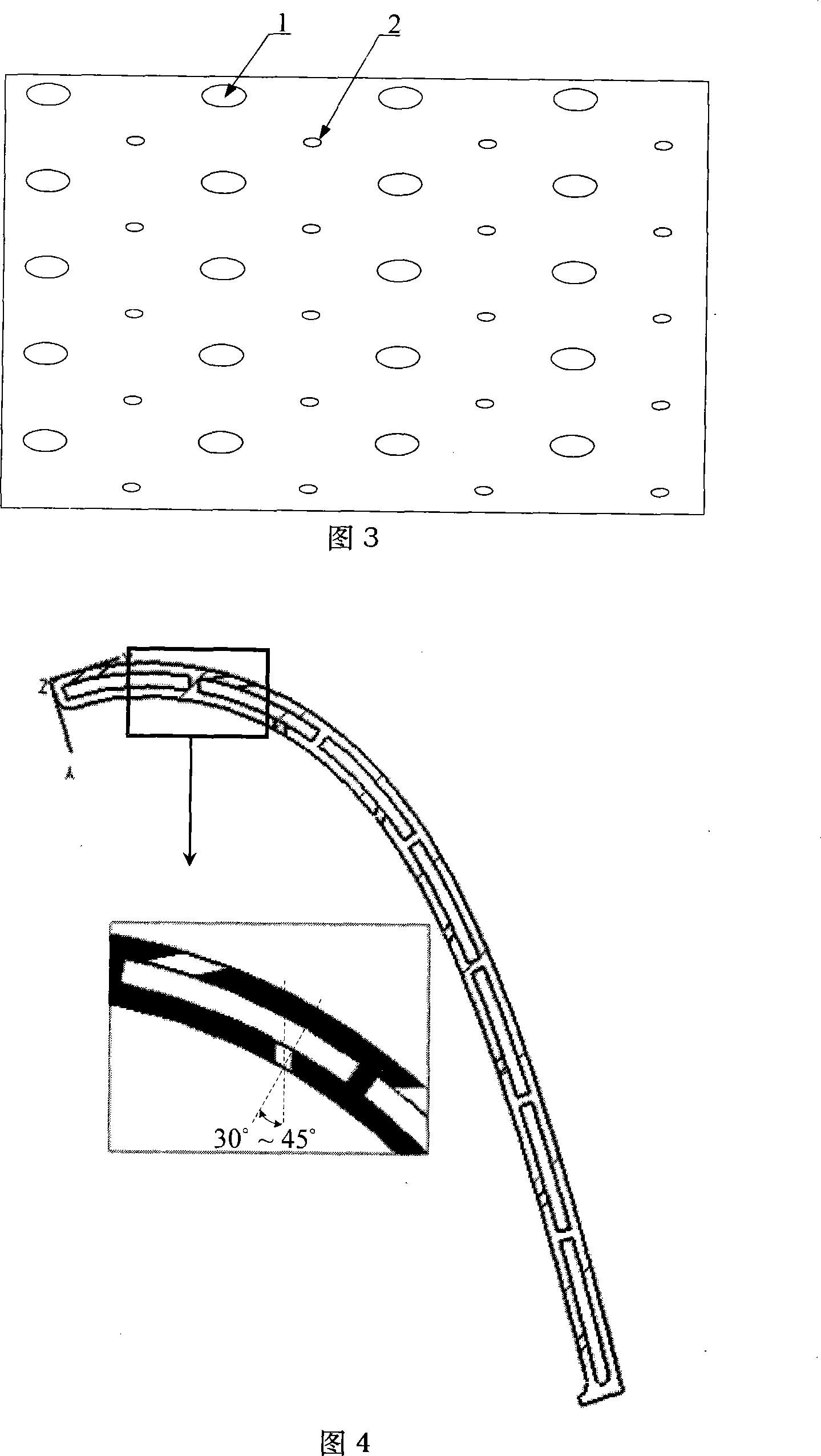

[0015] As shown in Fig. 1, a kind of combined cooling structure of the oblique impingement air-entrained film applied to the middle part of the turbine blade of the aeroengine comprises: air film holes and impact holes, and is characterized in that: a diameter of 1.0 mm is arranged on the outer surface of the blade mm~1.5mm air film holes, the number of each exhaust film hole in the span direction is 10~15, in the downstream area of the air film holes inside the blade, there are inclined impact holes with the same number as the air film holes, the impact hole angle 30°~45°, the center line of the impact hole is biased towards the direction of the air film hole, the impact hole is arranged downstream of the corresponding air film hole, the distance from the air film hole is 8 to 10 times the diameter of the impact hole, and the impact Holes and air film hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap