A use of a polyalkylmethacrylate polymer

A technology of polyalkyl methacrylate and methacrylate, which is applied in lubricating compositions, petroleum industry, etc., can solve problems such as non-existence, achieve small viscosity changes, improve low-temperature performance, and good shear stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10 and comparative Embodiment 1-3

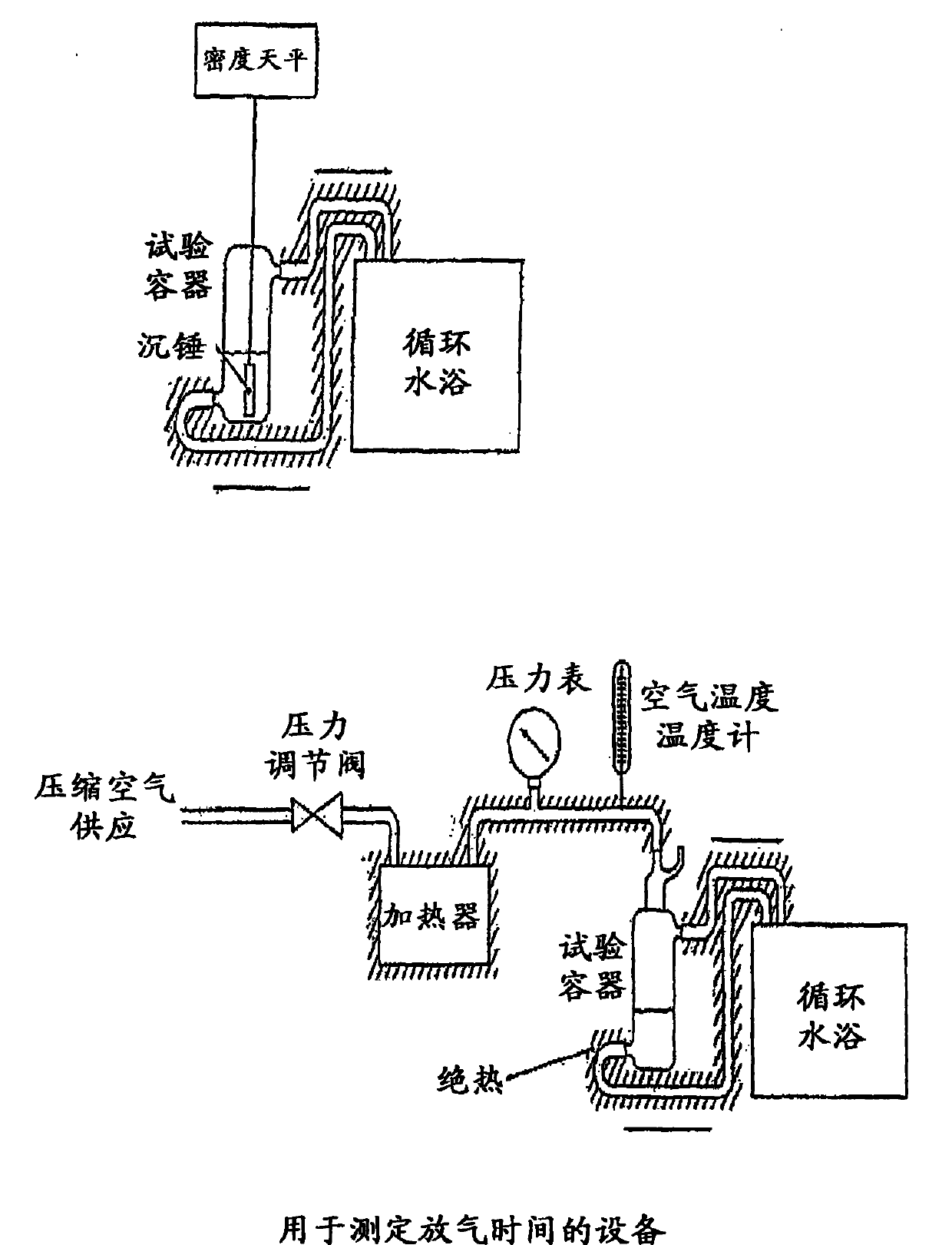

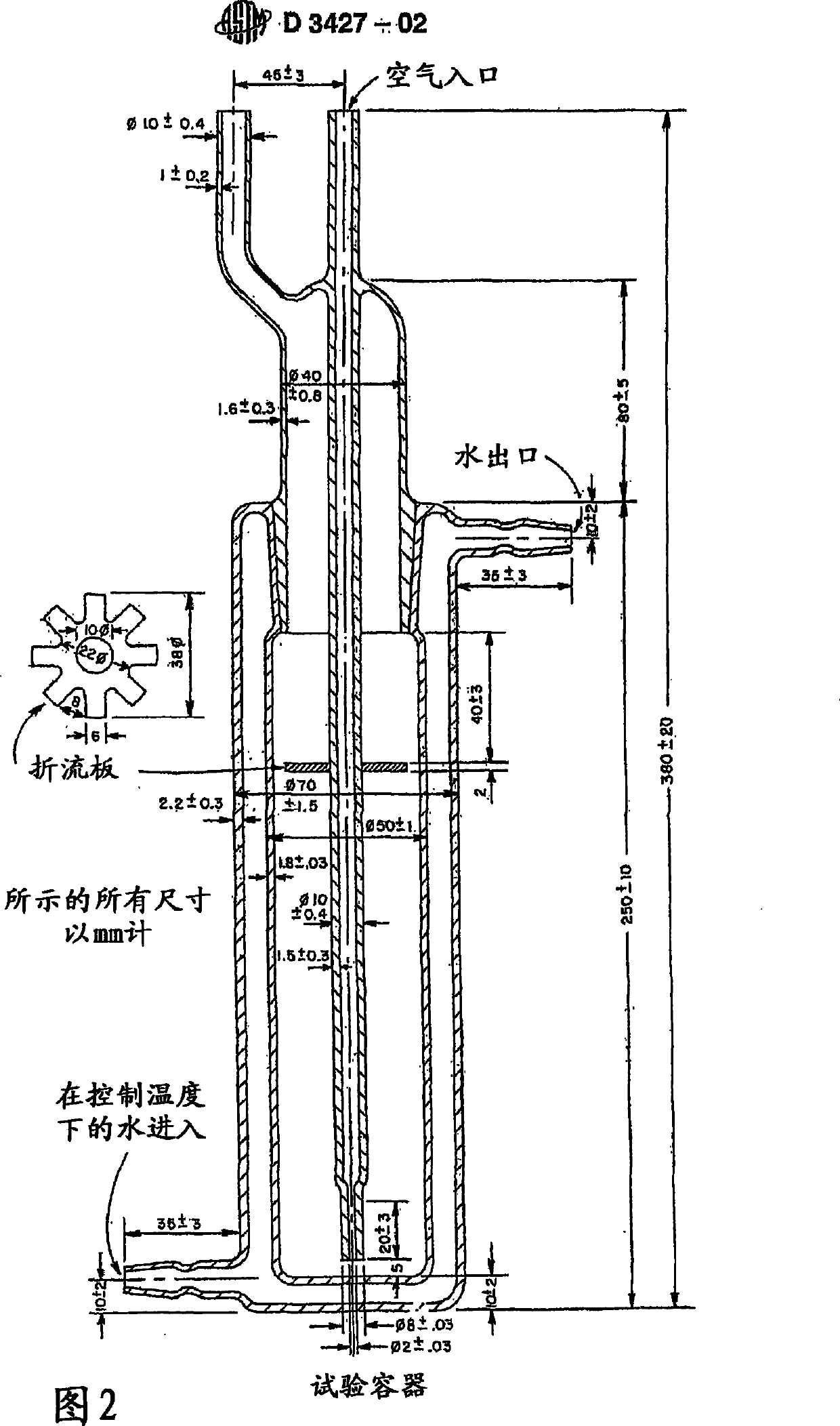

[0188] The fluid compositions of Examples 1-10 and Comparative Examples A-C have been prepared by mixing a Group I mineral oil base stock (combination of the following: 70N mineral oil = 70SUS solvent refined Group 1 paraffinic mineral oil; 100N Mineral oil = Class 1 paraffinic mineral oil refined by 100 SUS solvent; 150N mineral oil = Class 1 paraffinic mineral oil refined by 150 SUS solvent; 600BS mineral oil = 600 SUS bright stock Class 1 mineral oil). The fluids were mixed to achieve the viscosity data mentioned in Table 3. The PAMA polymer used was VISCOPLEX 8-219 available from RohMax Oil Additives. Slightly different base oil ratios are required to achieve the same viscosity at 40 and 50°C with and without PAMA polymer. The outgassing times of these fluids have been measured according to ASTM D3427.

[0189] Outgassing test details:

[0190] Transfer a 180ml fluid sample to a clean glass tube and allow the oil to equilibrate to the desired test temperature. The test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com