Low alcohol lychee wine and brewing method of the same

A technology of lychee wine and lychee, which is applied in the field of low-alcohol lychee wine and its brewing, can solve problems such as harm, achieve the effect of harmonious and pleasant aroma, retain nutritional and pharmacological value, and enrich product types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

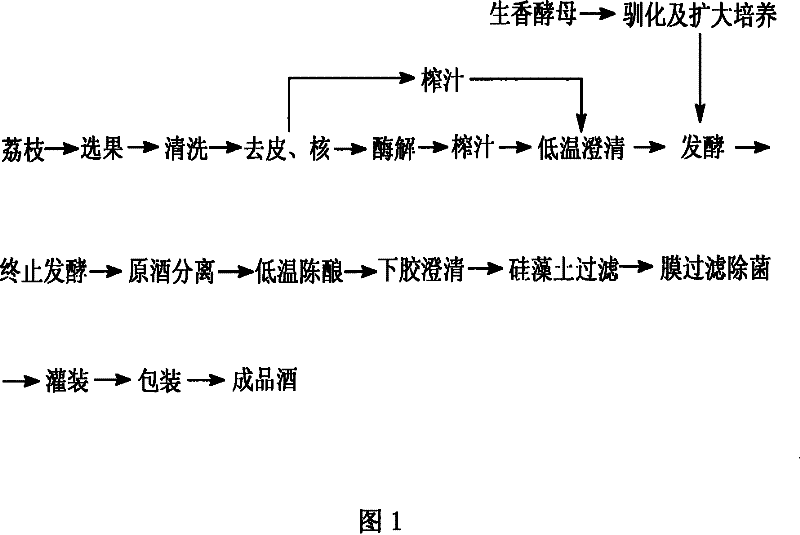

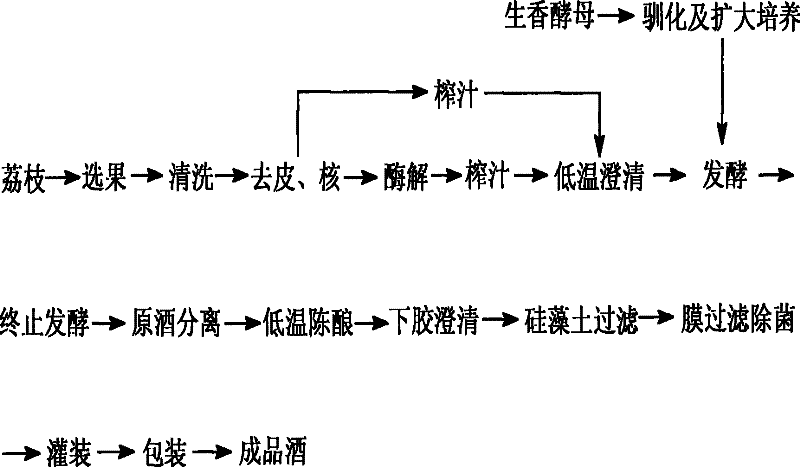

Method used

Image

Examples

Embodiment 1

[0025] (1) Raw material treatment, enzymatic hydrolysis, juicing and clarification: use Feizixiao lychee as raw material to remove insect damage, cracked fruit and moldy rotten fruit, and use effective SO 2 Soak in 100mg / L food-grade sulfurous acid aqueous solution for 10 minutes for disinfection, rinse with clean water; immediately add 1.0g of citric acid per kg of pulp after peeling and pitting the litchi, and adjust the litchi pulp with food-grade sulfurous acid solution with a concentration of 6%. Medium SO 2 The content is 150mg / kg, then add 30mg of pectinase per kg of pulp, mix well, place at 8°C for 24 hours, and squeeze the juice. The separated lychee juice is naturally clarified at 1°C, and the clear juice is separated and put into the fermenter. Add phosphoric acid to adjust the pH of the juice to 3.6.

[0026] (2) Fermentation: the fermentation process was carried out at pH 3.6, 20°C, SO 2 Under the condition of 150mg / L content, the abnormal Hansenula seed liquid ...

Embodiment 2

[0031] (1) Raw material treatment, enzymatic hydrolysis, juicing and clarification: use huaizhi litchi as raw material to remove insect damage, cracked fruit and moldy rotten fruit, and use effective SO 2 Soak in 150mg / L food-grade sulfurous acid aqueous solution for 5 minutes for disinfection, rinse with clean water; immediately add 2.5g citric acid per kg of pulp after peeling and pitting the litchi, and adjust the litchi pulp with food-grade sulfurous acid solution with a concentration of 6%. Medium SO 2 The content is 80mg / kg, then add 10mg of pectinase per kg of pulp, the enzyme activity of which is not less than 4200U / g, mix well and place it at 15°C for 5h, squeeze the juice, and stand the separated litchi juice at 12°C Clarify naturally, separate the clear juice into the fermenter, add phosphoric acid to adjust the pH of the juice to 4.0.

[0032] (2) Fermentation: at pH 4.0, 12°C, SO 2 The seed solution of Hansenula anomaly and Klerckia citriformum acclimated and ex...

Embodiment 3

[0037] (1) Raw material treatment, enzymatic hydrolysis, juicing and clarification: use black leaf lychee as raw material to remove insect damage, cracked fruit and moldy rotten fruit, and use effective SO 2 Soak in 120mg / L food-grade sulfurous acid aqueous solution for 8 minutes for disinfection, rinse with clean water; immediately add 2.0g of citric acid per kg of pulp after peeling and pitting the litchi, and adjust the litchi pulp with food-grade sulfurous acid solution with a concentration of 6%. Medium SO 2 The content is 120mg / kg, then add 20mg of pectinase per kg of pulp, mix well and place it at 10°C for 18h, then squeeze the juice. The separated lychee juice is allowed to stand at 7°C for natural clarification, and the clear juice is separated and put into the fermenter. Add phosphoric acid to adjust the pH of the juice to 3.8.

[0038] (2) Fermentation: the fermentation process will be carried out at pH 3.8, 15°C, SO 2 Content 120mg / L under the condition of acclimat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com