Cast-in-place shaping construction method and shaping equipment

A technology of forming equipment and construction methods, which is applied to the preparation of building components on site, construction, building components, etc., can solve the problems of single formwork structure and material, difficult to meet infrastructure construction, rigid implementation methods, etc., and achieve construction Convenience, sound insulation and shock resistance, smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

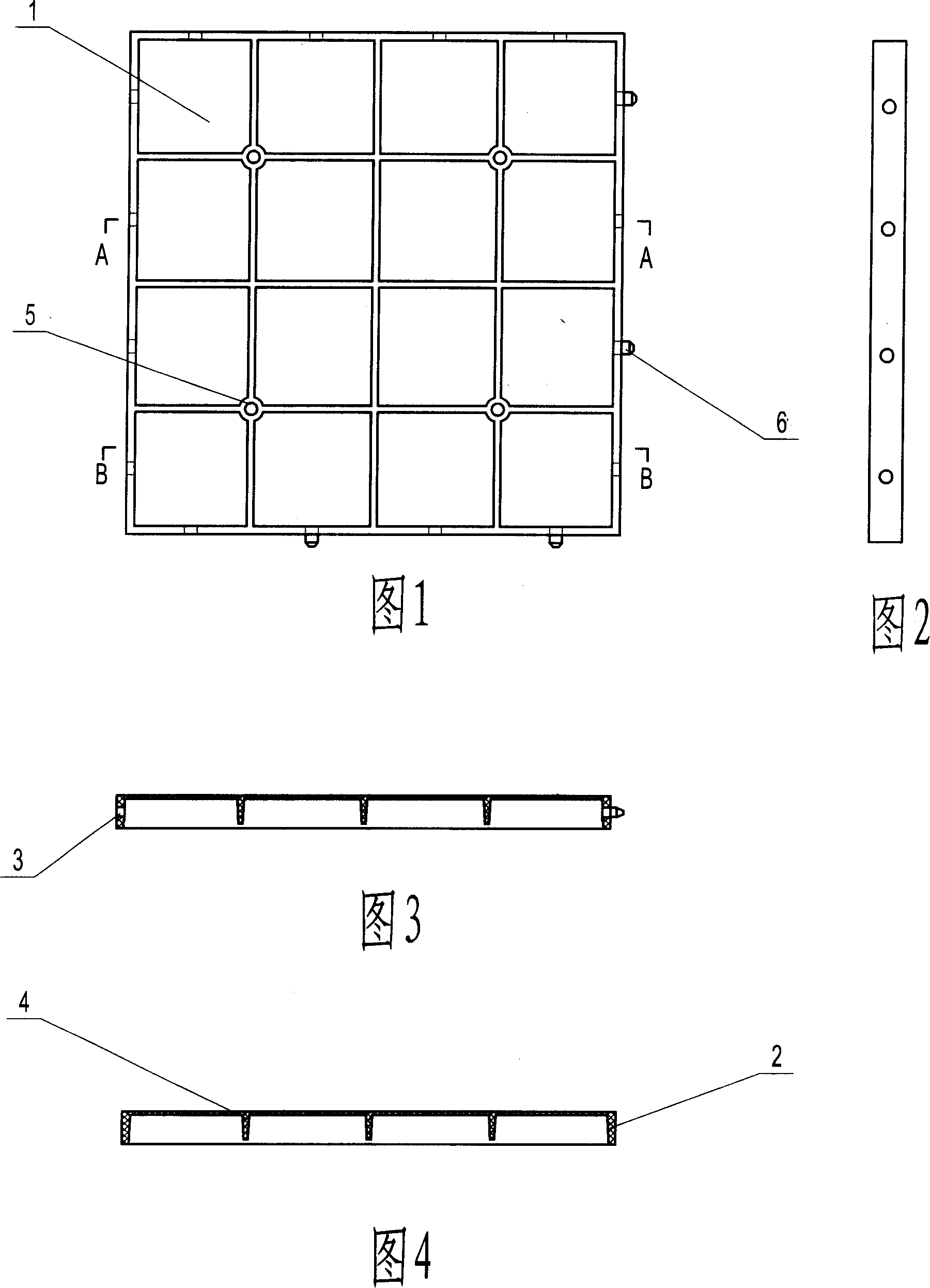

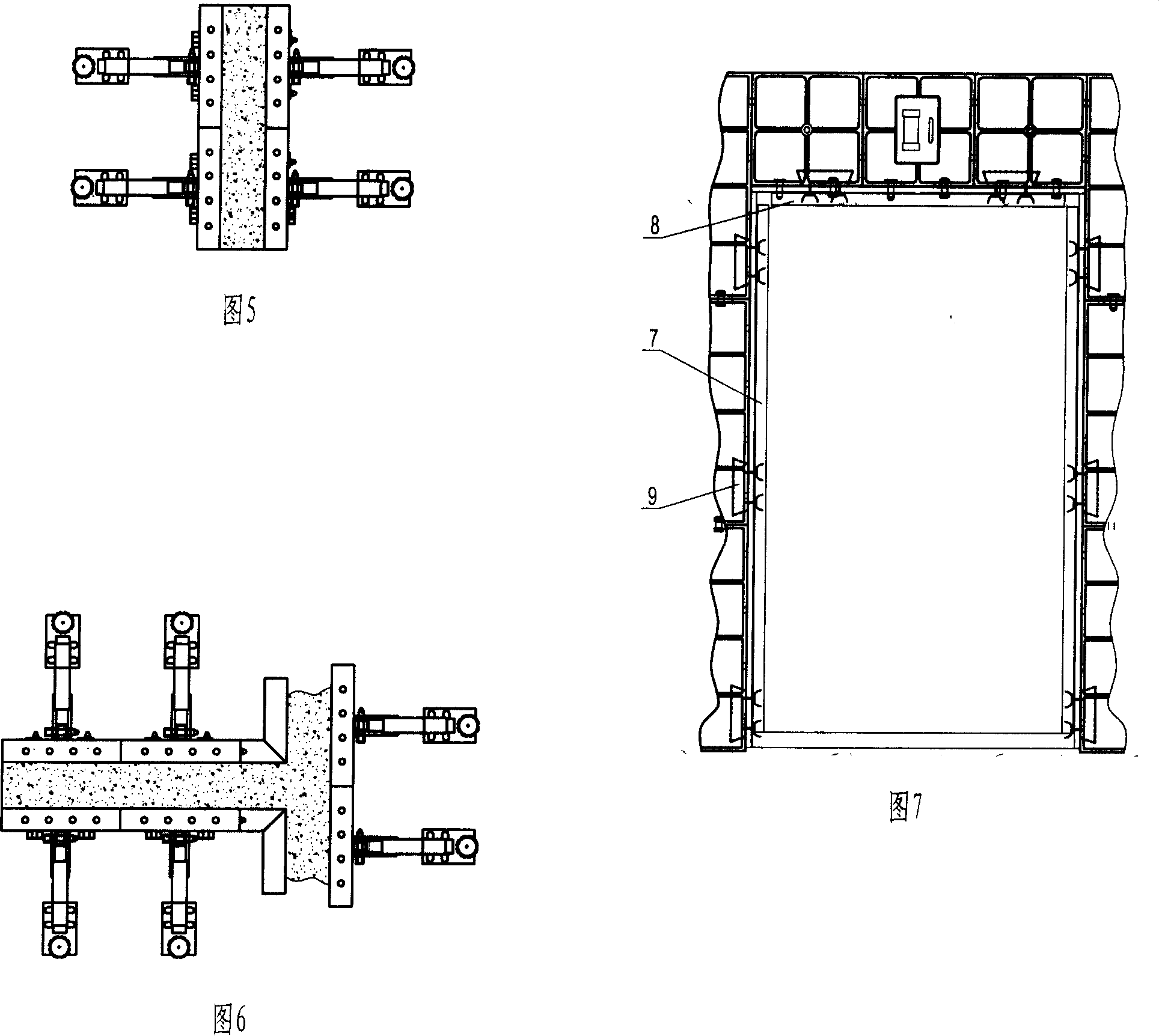

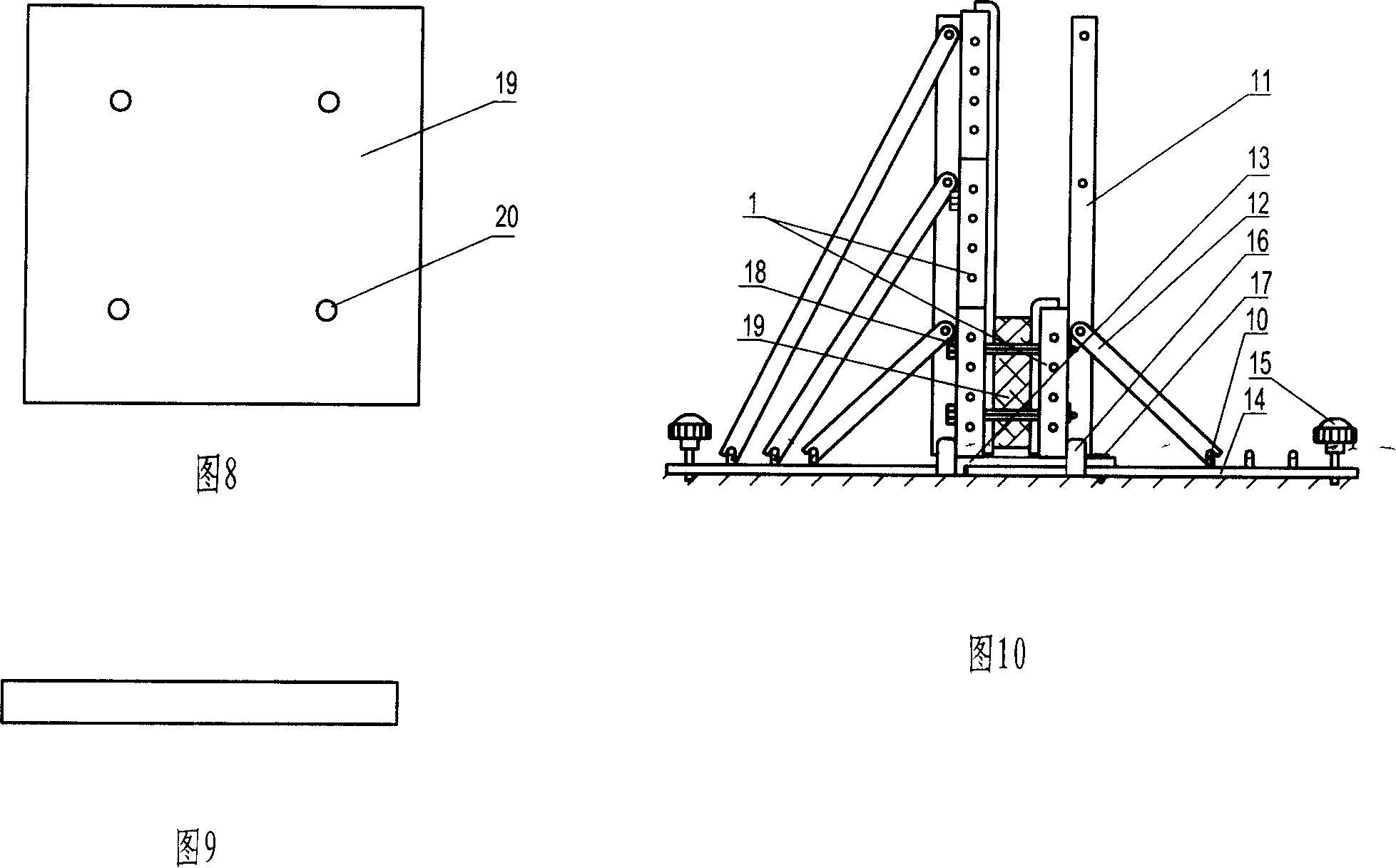

[0038] In the construction method of pouring-in-place molding for construction, first form the formwork into a whole formwork, place it on the wall to be formed, and adjust the whole formwork to the use requirements by adjusting the adjustment mechanism, and then continue to assemble the formwork group into another whole The template, the height of which is one template height, as shown in Figure 11, put the forming inner core between the two assembled overall templates, and then connect the two forming templates and the forming inner core through long positioning pins, and the forming inner core The positioning piece should be inserted into the hole first, and its length is equal to the thickness of the wall. The positioning of the forming inner core in the left and right direction is limited by the limit rubber strip 22. The locating pin 23 and the hole 3 on the forming template cooperate to realize positioning.

[0039] Inject the adjusted slurry between the two integral fo...

Embodiment 2

[0041] In-situ pouring molding construction method for construction, the forming formwork and forming inner core are assembled into a formwork height and the use status is adjusted as shown in Figure 14, and then the injection vibration process is completed into the mold cavity, and the second layer of wall is made in the same way After the second layer of wall is completed, the first layer of wall has reached the state of gelling and demoulding, and the forming template is removed to make the third layer of wall. Repeat the above-mentioned production process to complete the cast-in-place wall. If the demolition state is not reached, idle formwork can be used to make the remaining wall, as shown in Figure 15.

Embodiment 3

[0043] In the construction method of on-site pouring and forming for construction, the formwork is formed into two integral formworks, and the preformed wall panels are clamped and cast in any of the above-mentioned implementation methods. The preformed wall panels can be placed vertically as shown in Figure 16, or It can be placed horizontally as shown in Fig. 17, wherein the preformed wallboard is a pouring area at a certain distance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com