Integrating controller of CD driver optical reading head and holding tray motor and control method thereof

A technology of optical reading head and controller, which is applied in the direction of optical recording/reproduction, instrument, head configuration/installation, etc., so as to avoid mutual interference and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

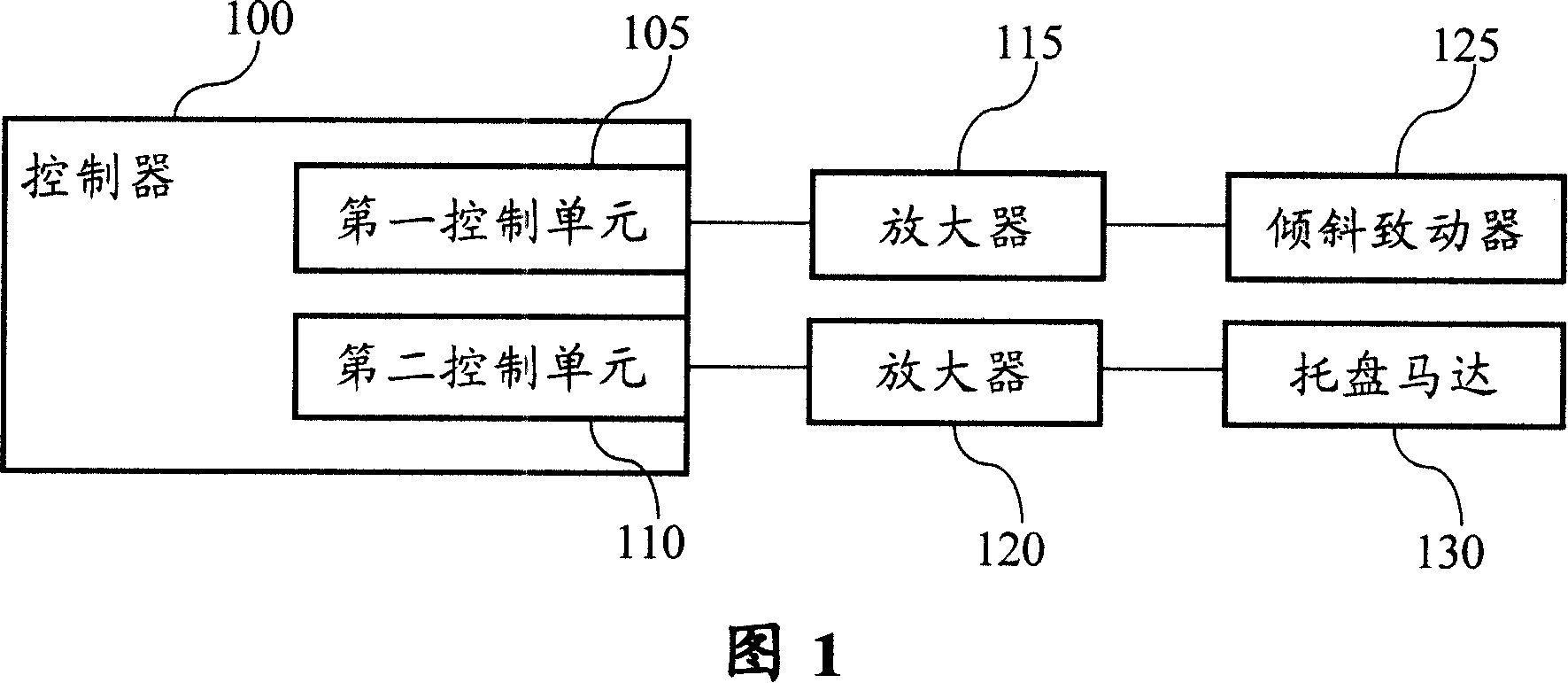

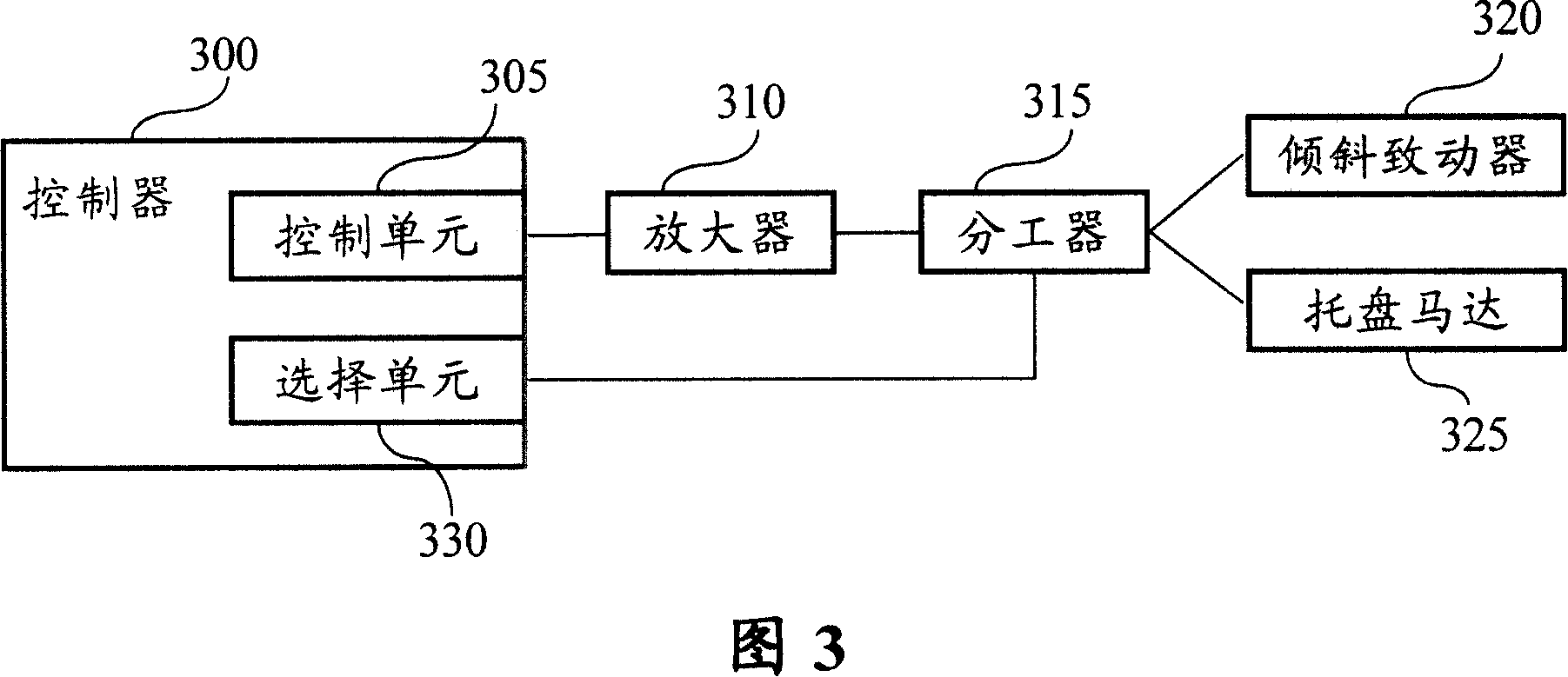

[0028] Please refer to FIG. 3 , which is a block diagram of a first embodiment of the present invention. The first embodiment of the present invention includes a controller 300 , an amplifier 310 , a divider 315 , a tilt actuator 320 , and a tray motor 325 . The controller 300 includes a control unit 305 and a selection unit 330 . The controller 300 transmits the control signal to the control unit 305, and the control unit 305 transmits the control signal to the amplifier 310 according to the transmitted control signal. The selection signal at 330 outputs a control signal to the tilt actuator 320 or the tray motor 325 to make corresponding actions.

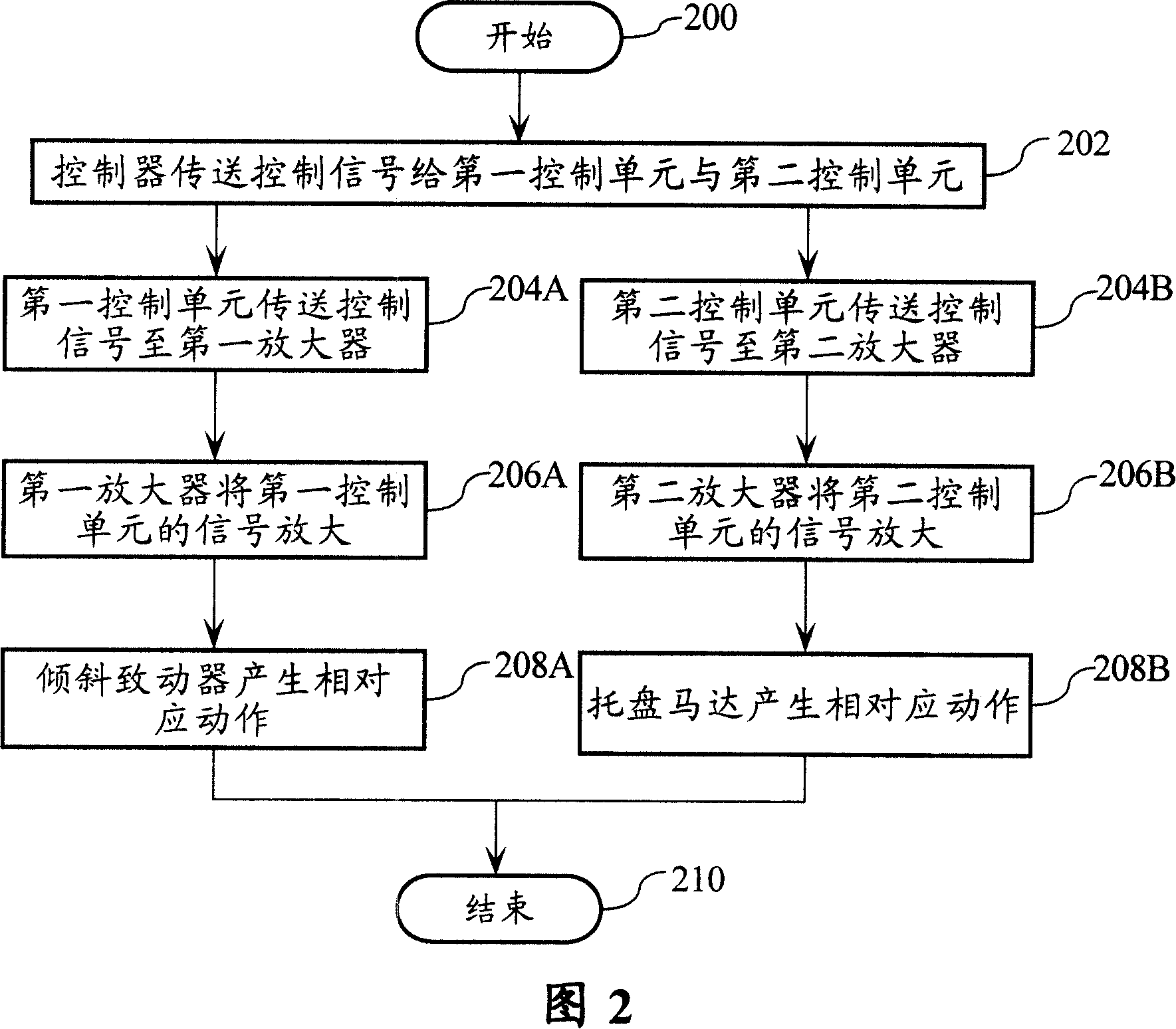

[0029] Please refer to FIG. 4 , and refer to FIG. 3 . Fig. 4 is a flowchart of the first embodiment of the present invention. The instructions are as follows:

[0030] Step 400: start;

[0031] Step 402: the controller 300 sends a control signal to the control unit 305 and the selection unit 330;

[0032] Step 404: the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com