Valve for a contact tray

A technology of contact plate and valve body, which is applied in the field of contact plate valves, can solve the problems of non-existence, wide working range, etc., and achieve the effect of fast installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

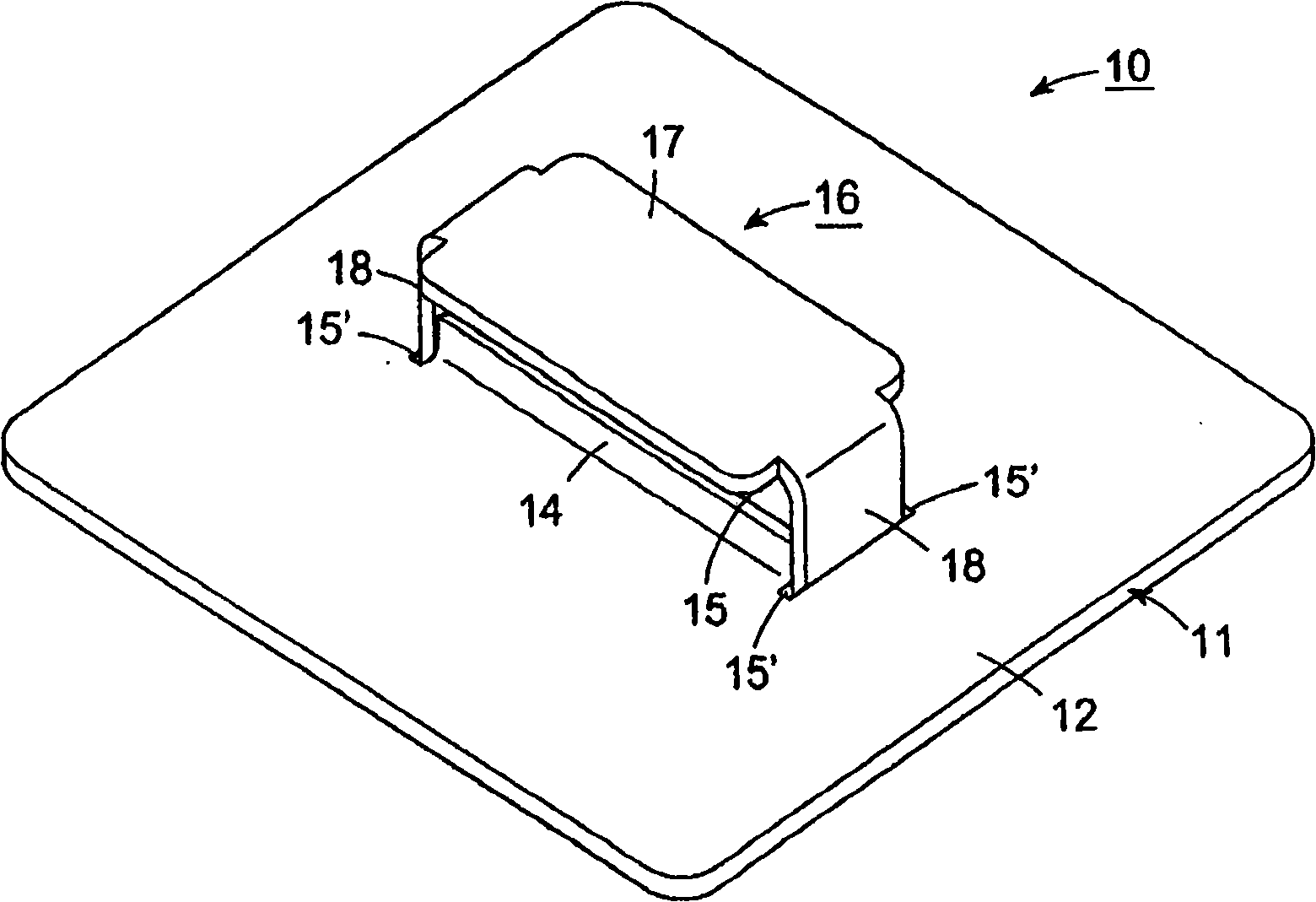

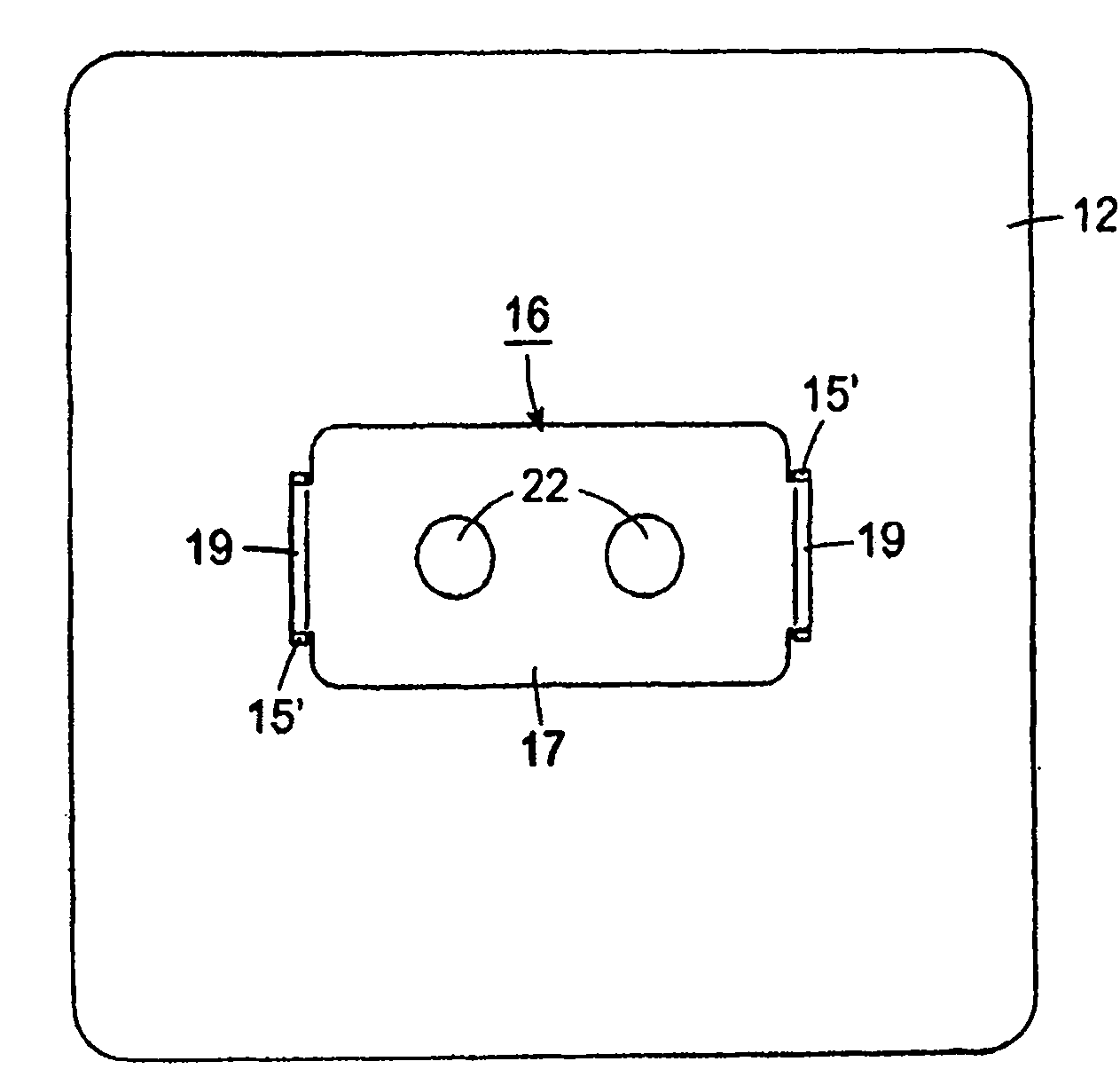

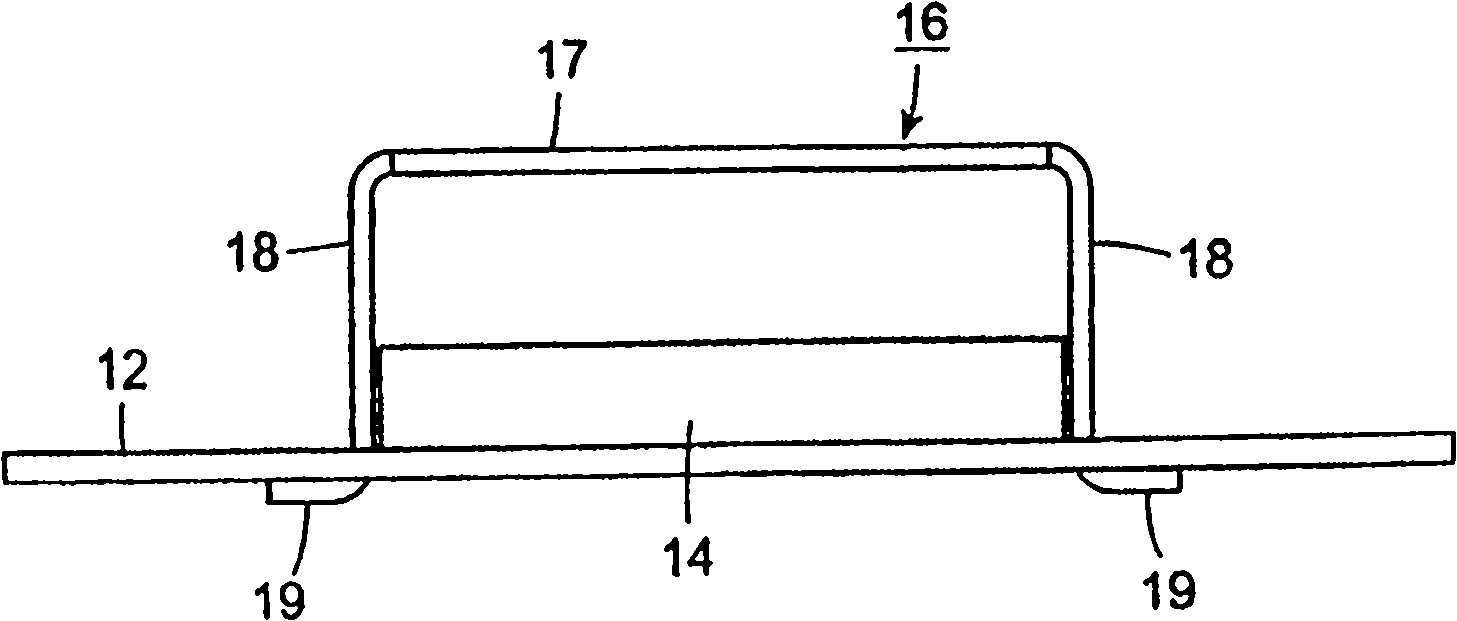

[0038] refer to figure 1 , the injection valve 10 is particularly suitable for use in a contact tray 11, for example, in a distillation column using a downcomer. The valve 10 may be of the fixed type or of the movable (floating) type. figure 1 A valve 10 of movable type is shown.

[0039] As shown, the contact plate 11 has a deck 12 for receiving a liquid flow thereon and a number of valves 10 (only one of which is shown) positioned in a row-by-row arrangement in a staggered array. In the plate surface 12, for example, in a triangular angle, or in a rectangular array, for example with right angles. Each valve 10 has a pair of parallel opposing walls 14 extending upwardly from the deck 12 to define an aperture 15 in the rectangular deck 12 for ascending steam flow, and a single-piece valve body 16. is arranged in the aperture 15 so as to move under the influence of the ascending steam flow from a closed position on the wall 14 to a raised position above the wall 14 (as shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com