Feeder unit of the centrifugal discharging type centrifugal machine

A technology for unloading centrifuges and feeding devices, which is applied to centrifuges and centrifuges with rotating drums, etc. It can solve problems such as discontinuous working process, centrifuge vibration, and prone to mechanical failures, so as to reduce mechanical Failure, smooth operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

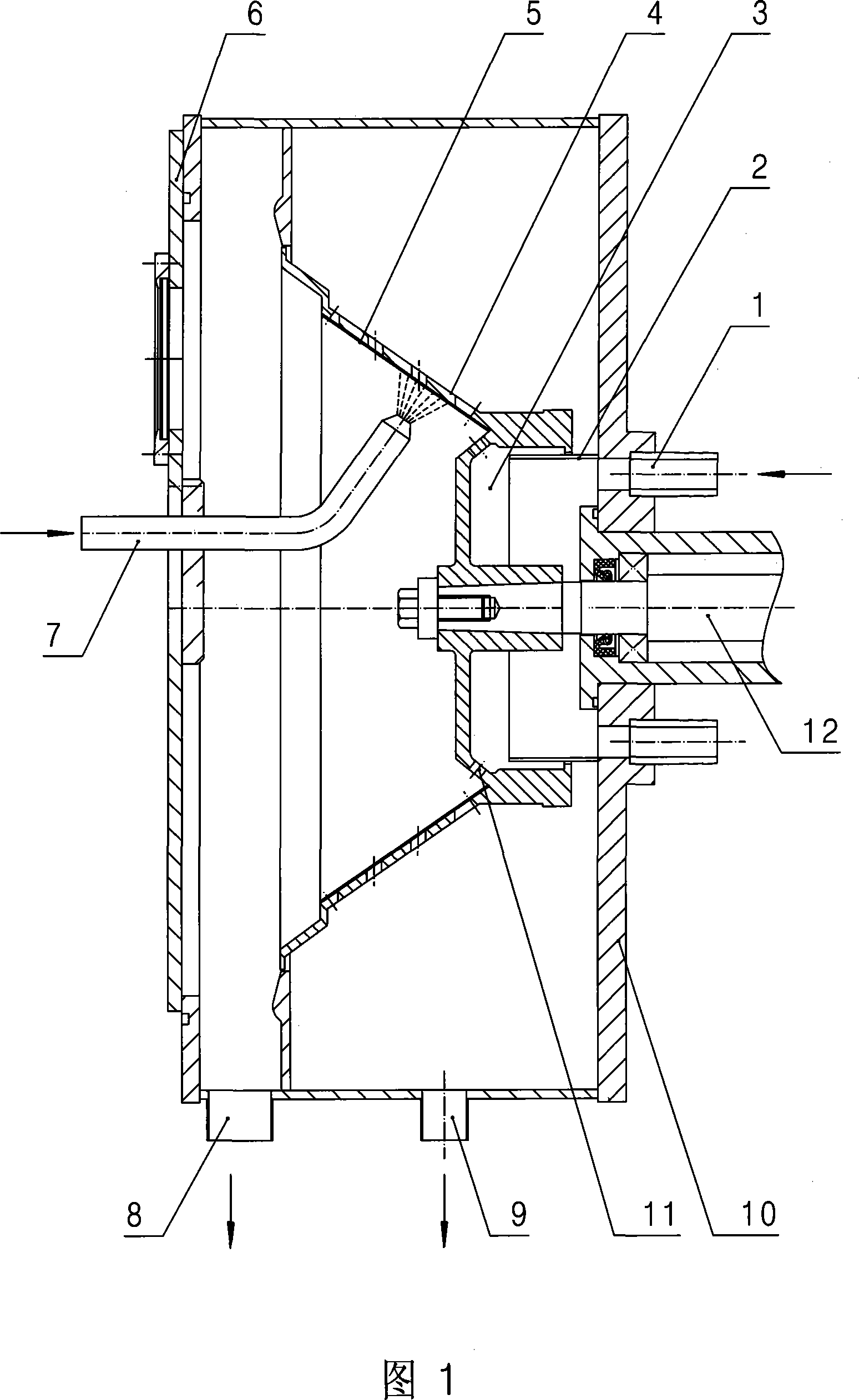

[0009] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] As shown in Figure 1, the feeding device in the centrifugal discharge centrifuge of the present invention includes: a casing 10, a main shaft 12 driven by a main shaft motor is movably arranged in the casing 10, and a drum is arranged on the main shaft 12 4. The outer side of the bottom of the drum is sunken inward to form a silo 3, the bottom of the silo 3 communicates with several evenly arranged feed holes 11 arranged on the same circumference at the bottom of the drum 4; the inner wall of the casing 10 A hopper 2 matched with the silo 3 is provided, and the hopper 2 communicates with several feed pipes 1 pierced in the casing 10 . In this embodiment, the several feed pipes 1 are evenly passed through the casing 10 with the main shaft 12 as the center.

[0011] The working process of the centrifuge equipped with the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com