Device for gluing the back lining paper or the headband

A technology of perfect binding and book spine, which is applied in the direction of adhesives for binding, book binding, adhesives, etc., to achieve the effect of improving the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

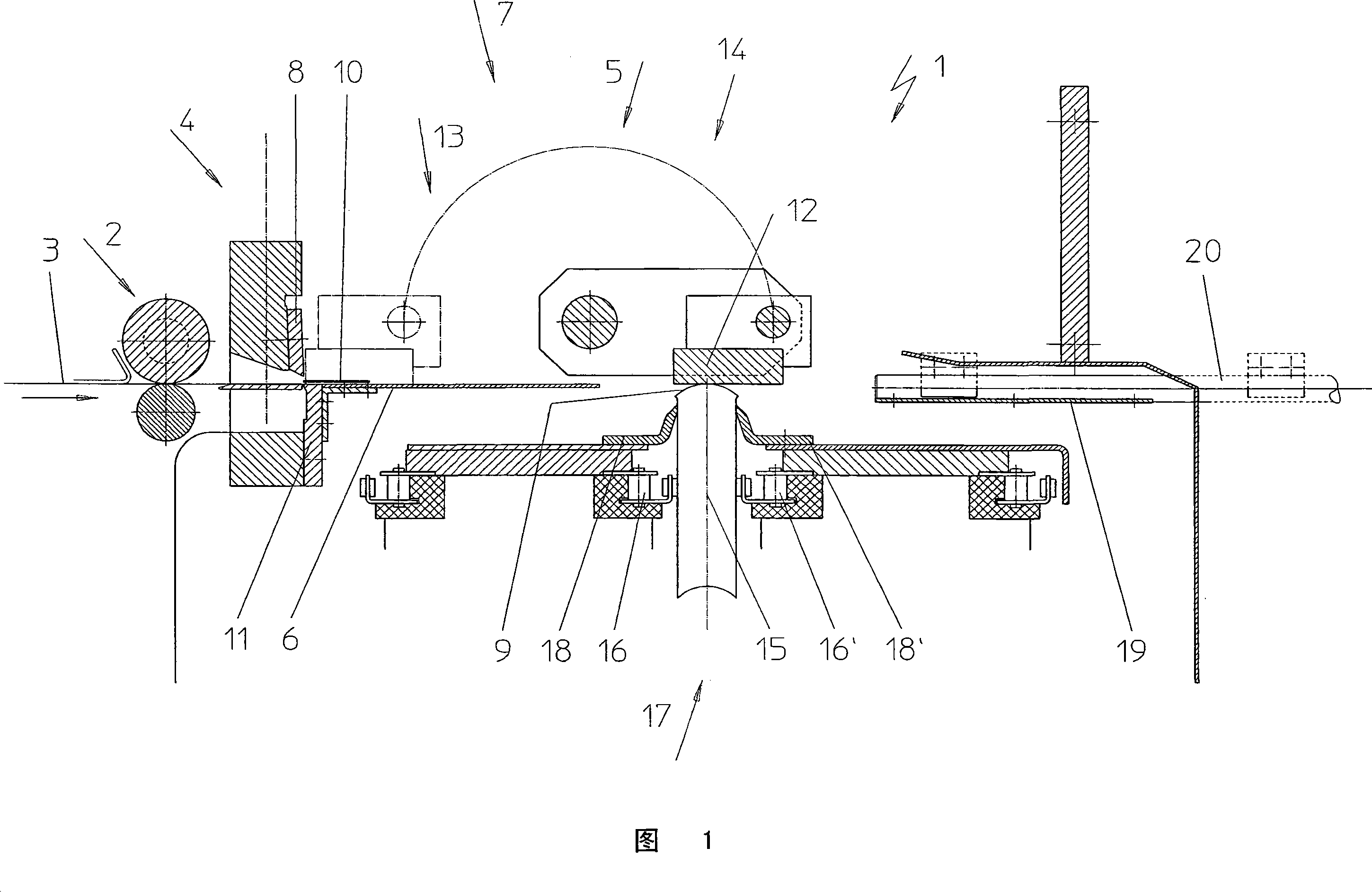

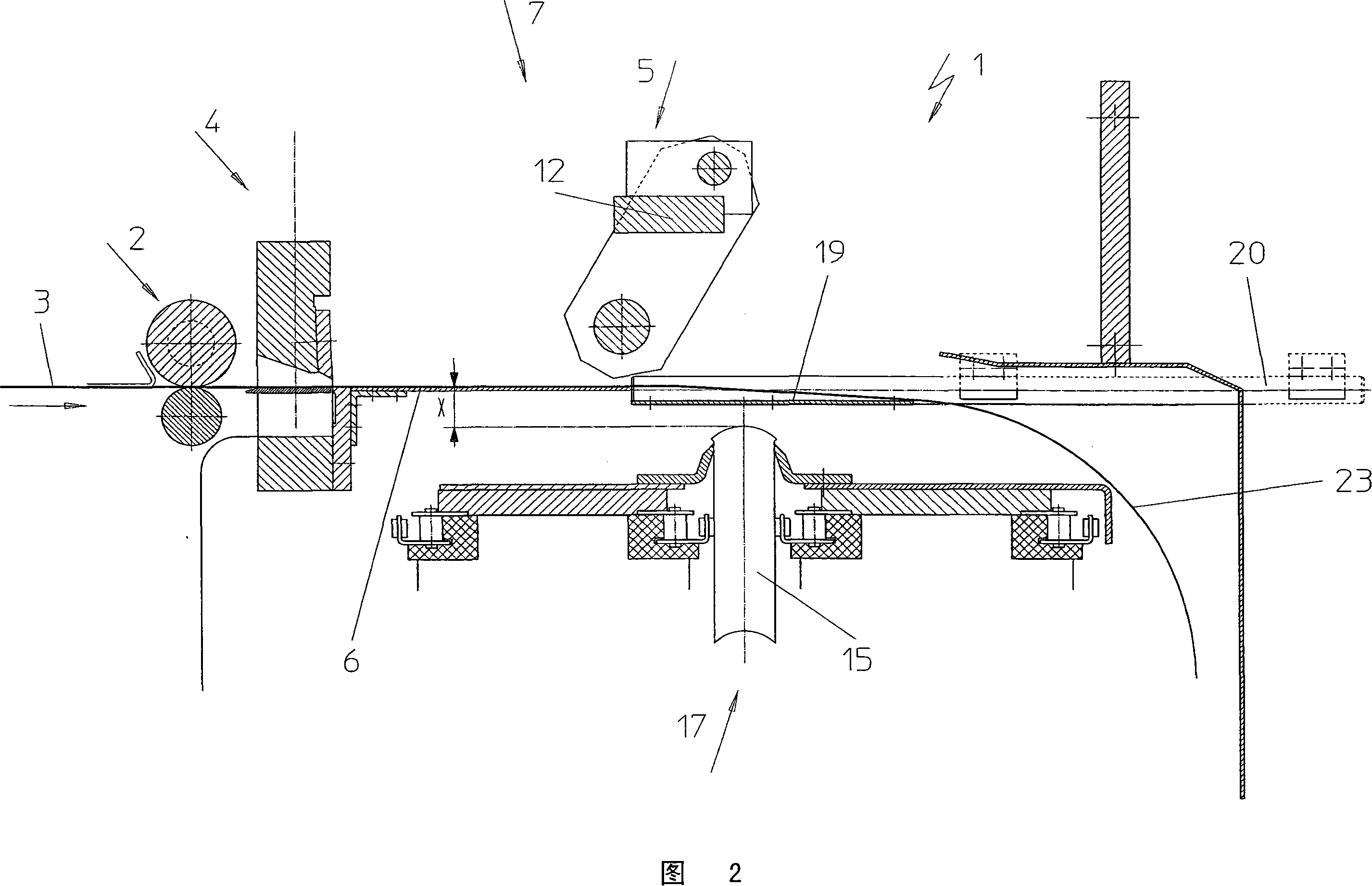

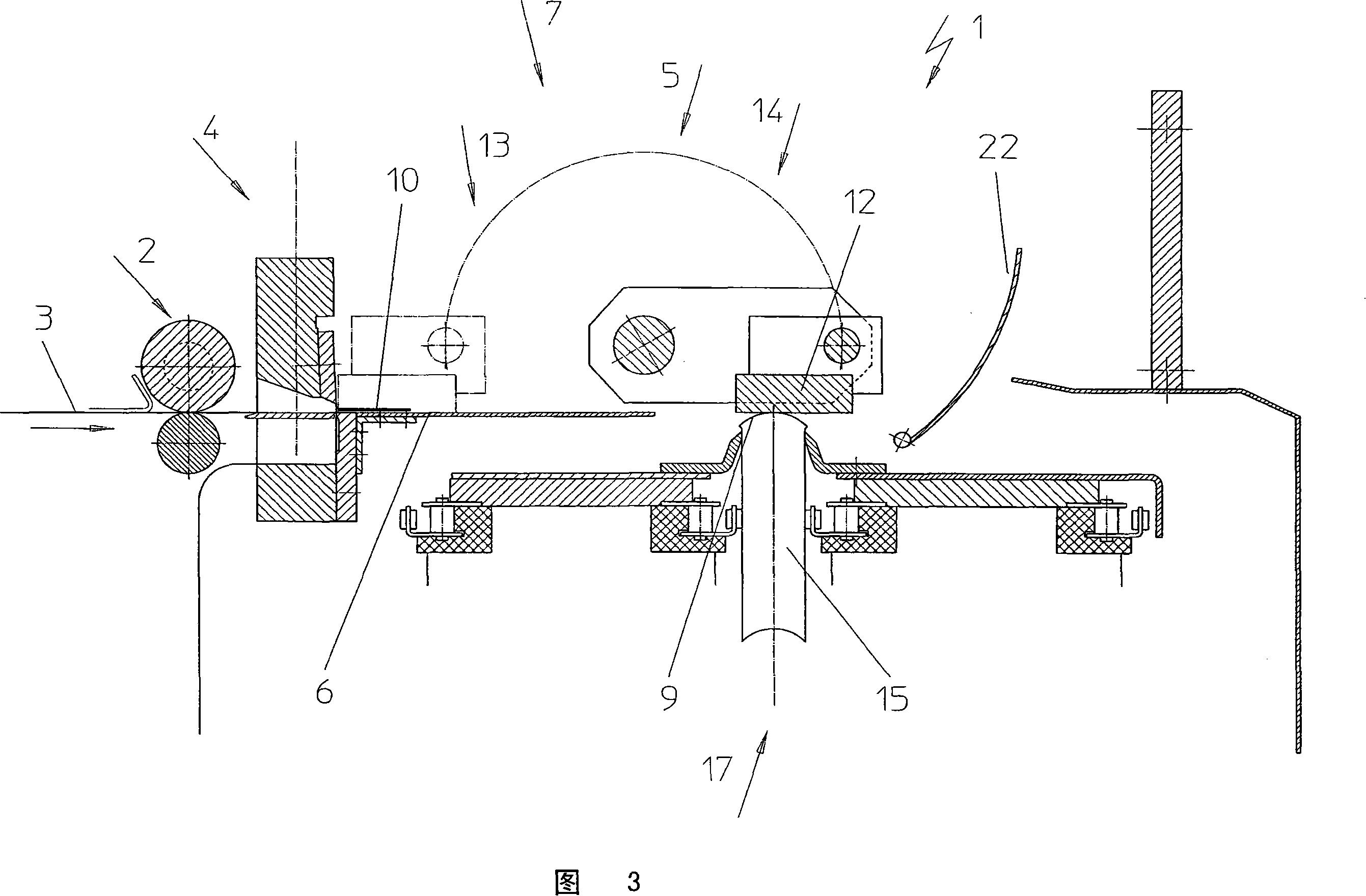

[0022] FIG. 1 shows a cross-section of a book line in the area of a perfect binding station with a device 1 for perfect binding or reinforcing the spine. The perfect binding material 3 is fed from a storage device into a unit 7 consisting of a cross cutter 4 , a transport device 5 and a support table 6 by means of a feed device 2 which is transported perpendicularly to the book line. Simultaneously, the input mechanism 2 feeds, for example, the tape-shaped binding material 3 previously cut to the correct length with a disc knife and provided with a spine reinforcement band under the upper blade 8 in the upper position of the cross-cutting machine 4 and 9 coordinated widthwise dimensions of the core and sub-spine of the book. The fed perfect binding section 10 of the perfect bound material 3 now lies flat on the support table 6 adjacent to the lower blade 11 of the cross cutter 4 .

[0023] The suction plate 12 of the transport mechanism 5 , which is oriented parallel to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com