Air spinning machine with monitoring of the spinning process by means of sensors

An open-end spinning machine and sensor technology, which is used in continuous winding spinning machines, spinning machines, open-end spinning machines, etc., can solve the problems of blocking vortex chambers, fibers not being sucked away, and air vortex interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

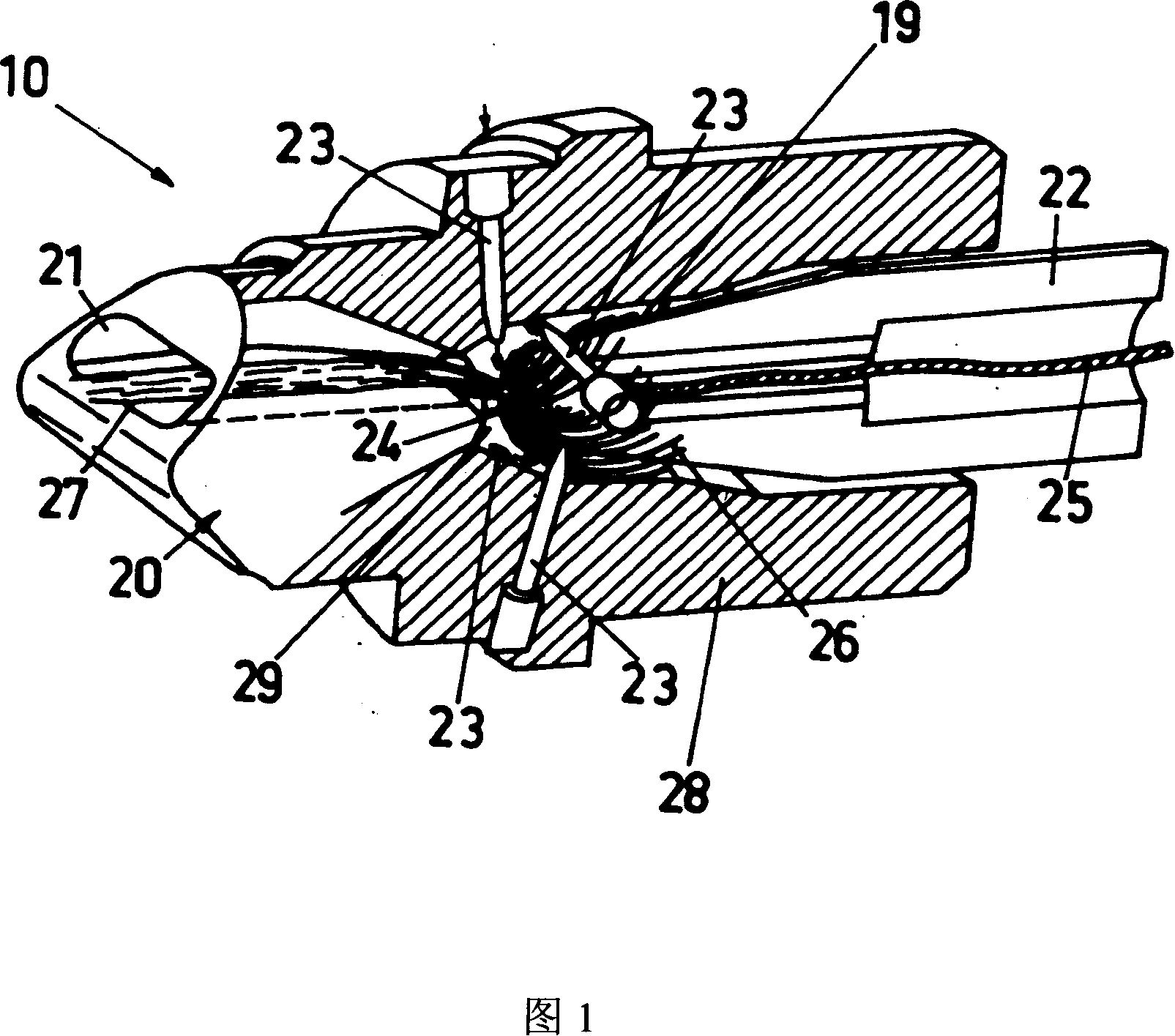

[0024] In order to explain the facts described hereinafter, FIG. 1 shows a perspective view of a spin pot 10 known per se, hereinafter referred to as spindle 10 , comprising a thread-guiding element 20 and a spindle 22 . The yarn sliver 27 is guided through the yarn guide element 20 into the swirl chamber 29 as far as the spindle hole 24 . The vortex created by the compressed air supplied by the air nozzle 23 spins the sliver 27 into a yarn 25 which is drafted through the yarn drawing channel of the spindle 22 to a winding device (not shown). Figure 1 does not show exactly the air duct 19, which is used to expel the air and release the fibres.

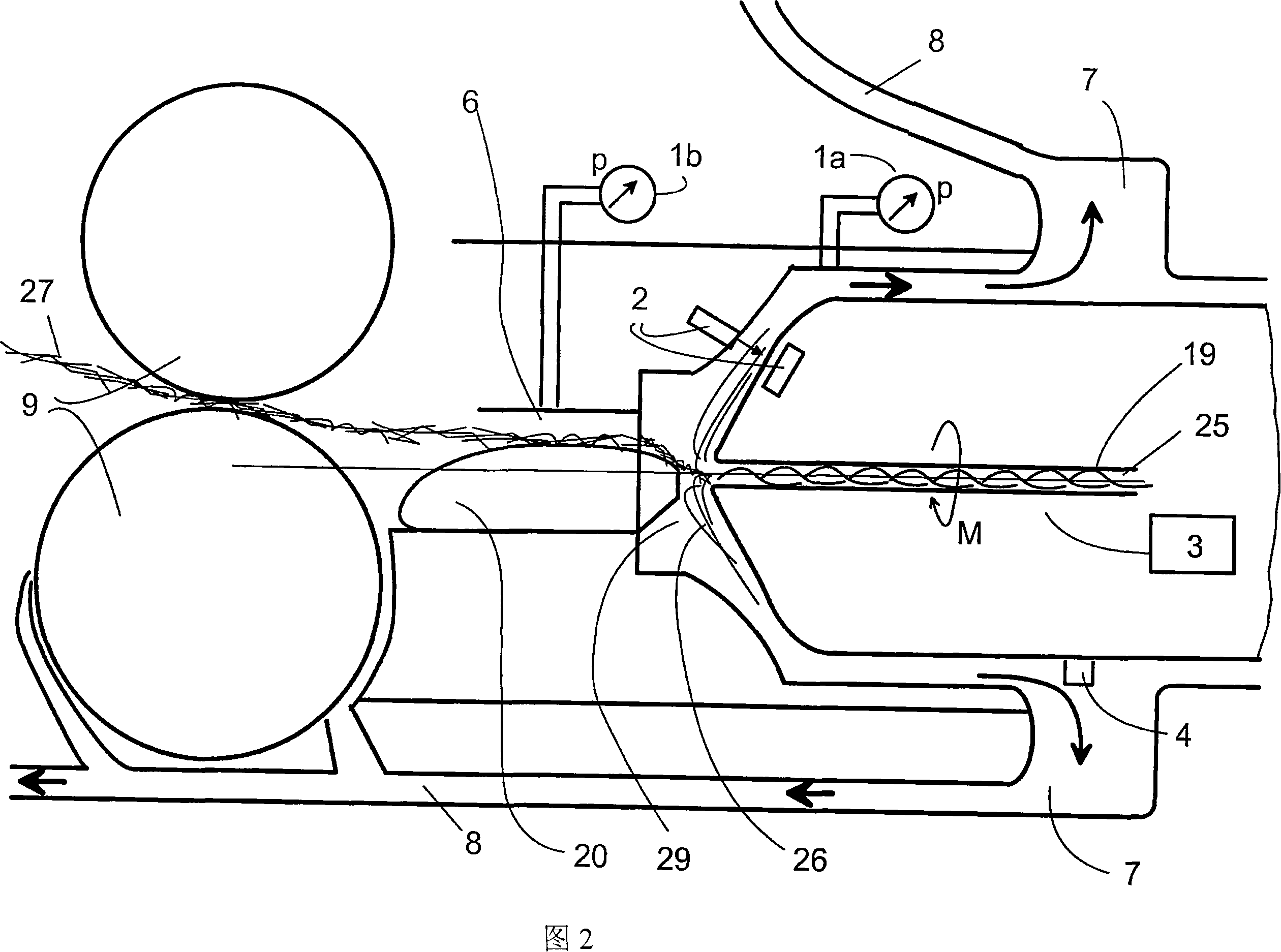

[0025] From the context of figure 1, figure 2 shows a particular arrangement of sensors at the spinning spindles in an embodiment of the spinning machine according to the invention. It should be noted here that the type and number of sensors shown can be freely combined.

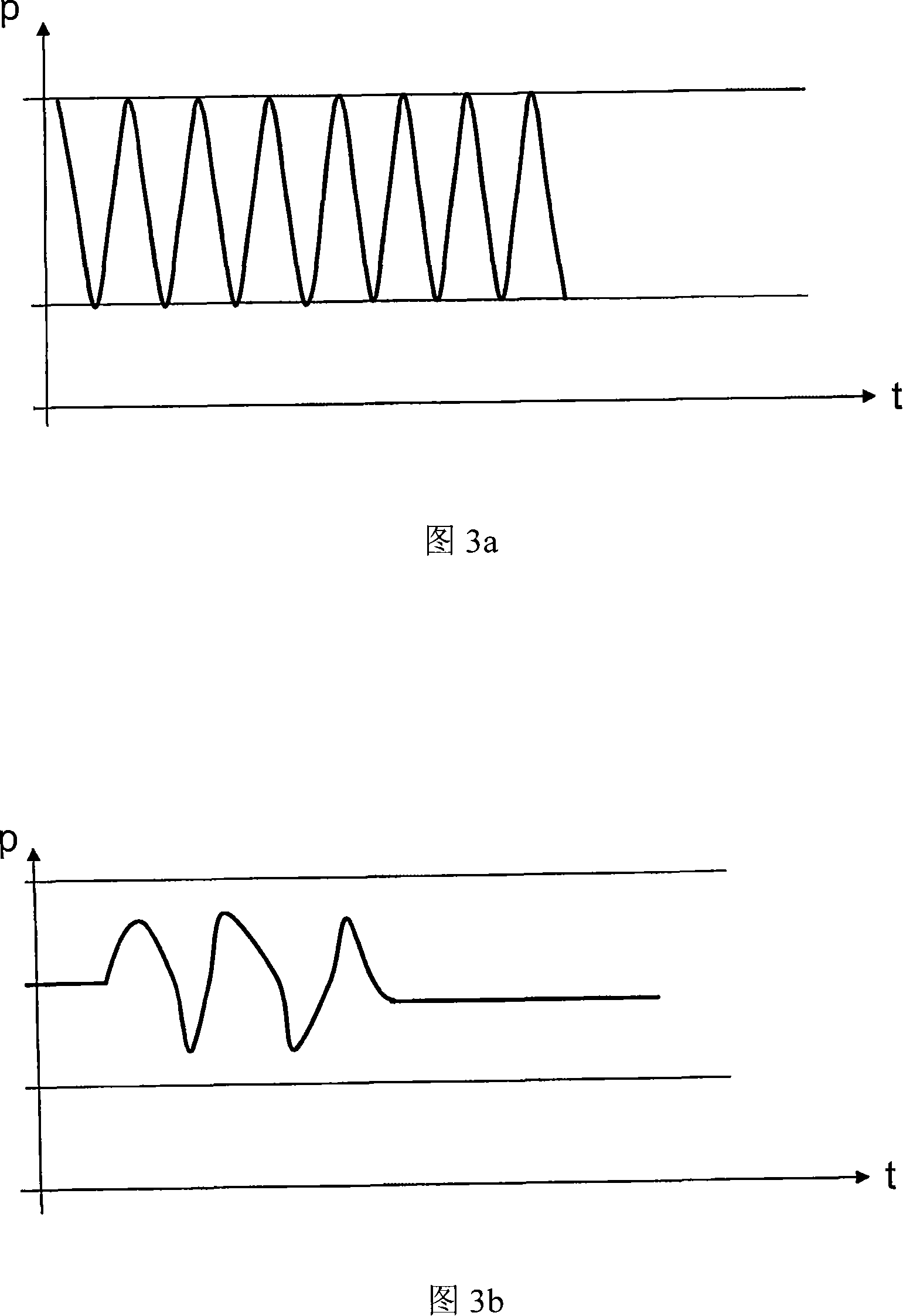

[0026] As is known, during the air-jet spinning process so-ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com