Gas sensor and method for the production thereof and uses

A sensor and gas technology, applied in gas sensors and their manufacturing and application fields, can solve problems such as gas sensor failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

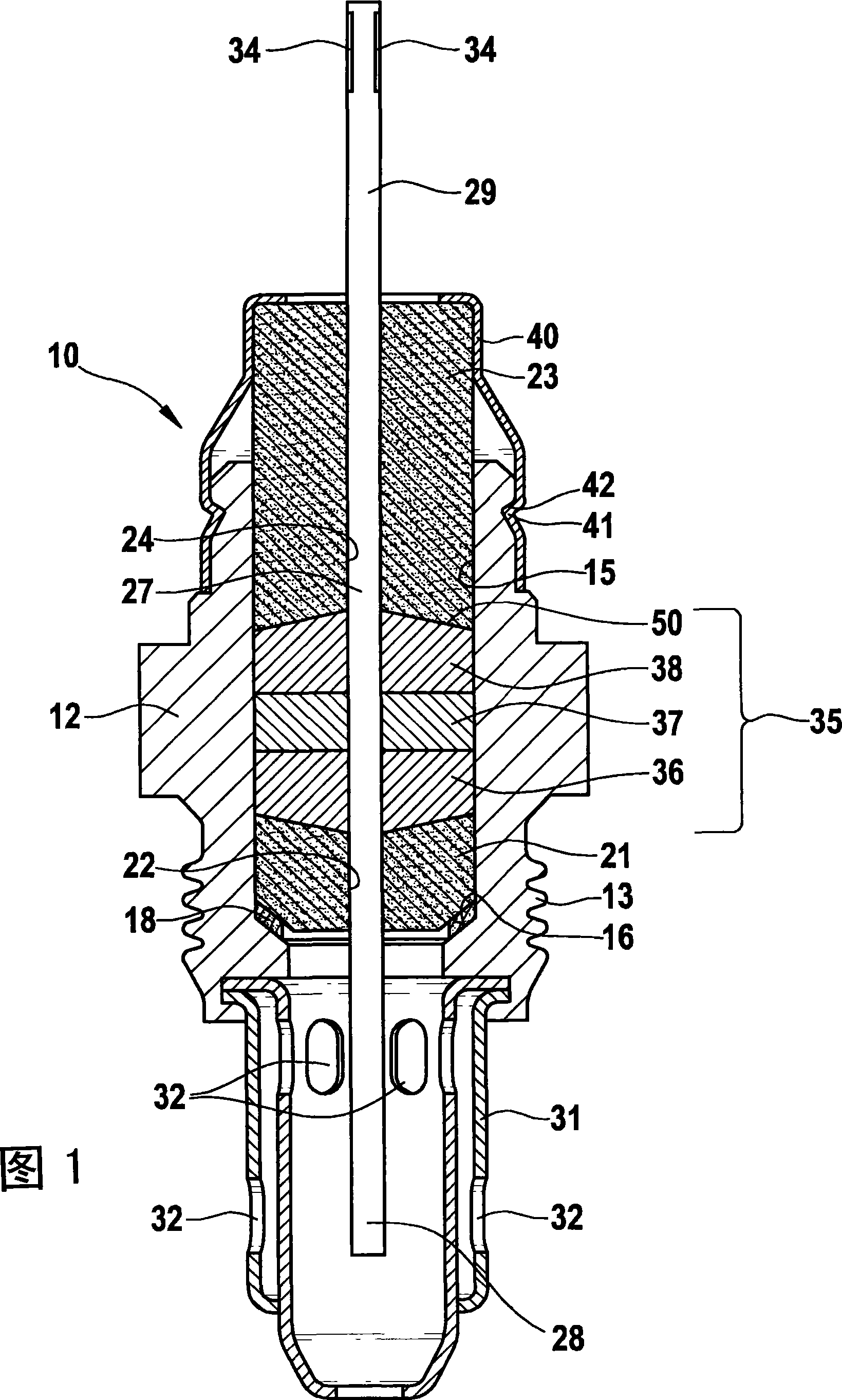

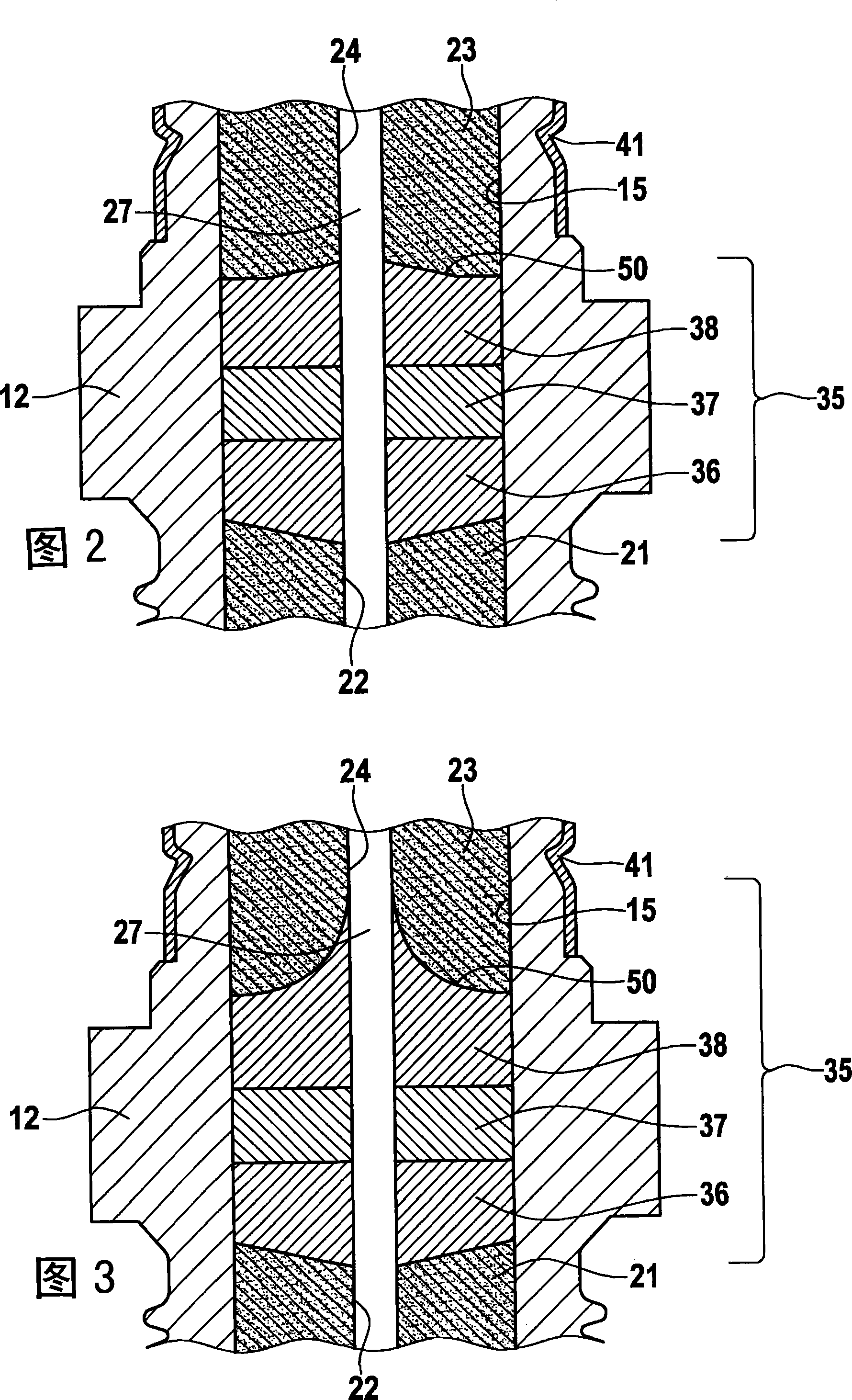

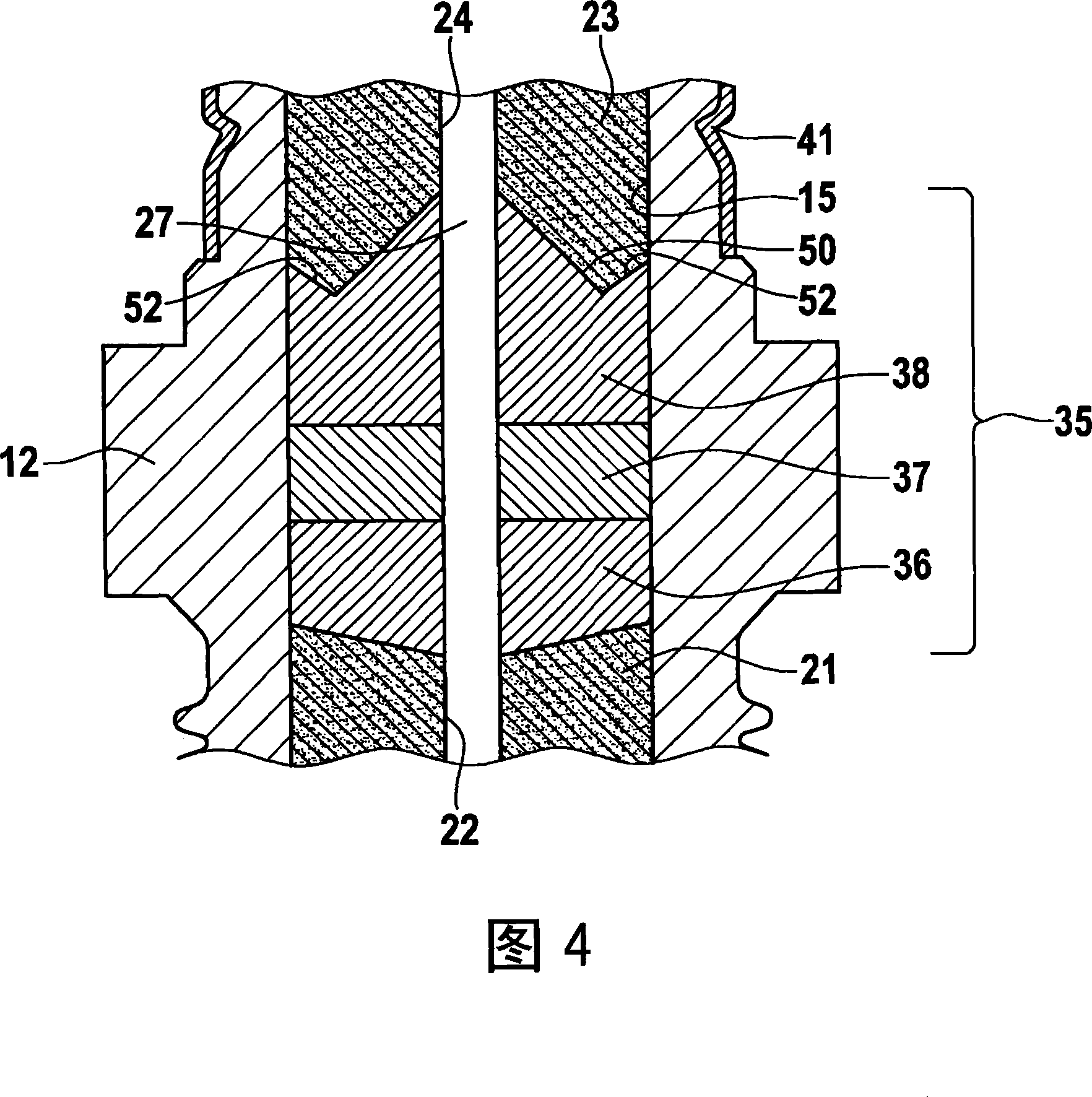

[0027] figure 1 shows the schematic structure of a sensor for determining a gas in a gas mixture. The sensor 10 is, for example, an electrochemical oxygen sensor, which includes a metal housing 12, which has a screw thread 13 as a fixing mechanism for being installed in a not shown gas pipe to be measured. The gas line is configured, for example, as an exhaust gas conduction system. The housing 12 has a longitudinal bore 15 with a shoulder-shaped annular surface 16 . For example, a metallic sealing ring 18 rests on the shoulder-shaped annular surface 16 , against which a measured gas-side ceramic molding 21 rests. The measured-gas-side ceramic molding 21 has a centrally arranged, measured-gas-side through-opening 22 extending in the direction of the longitudinal bore 15 . A connection-side ceramic molding 23 is also provided in the longitudinal bore 15 at a distance from the measured gas-side ceramic molding 21 . The connection-side ceramic molding 23 also has a centrally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com