Tread splicing apparatus

An automatic jointing and treading technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of reduced productivity, length change, overlapping of tread jointing states, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

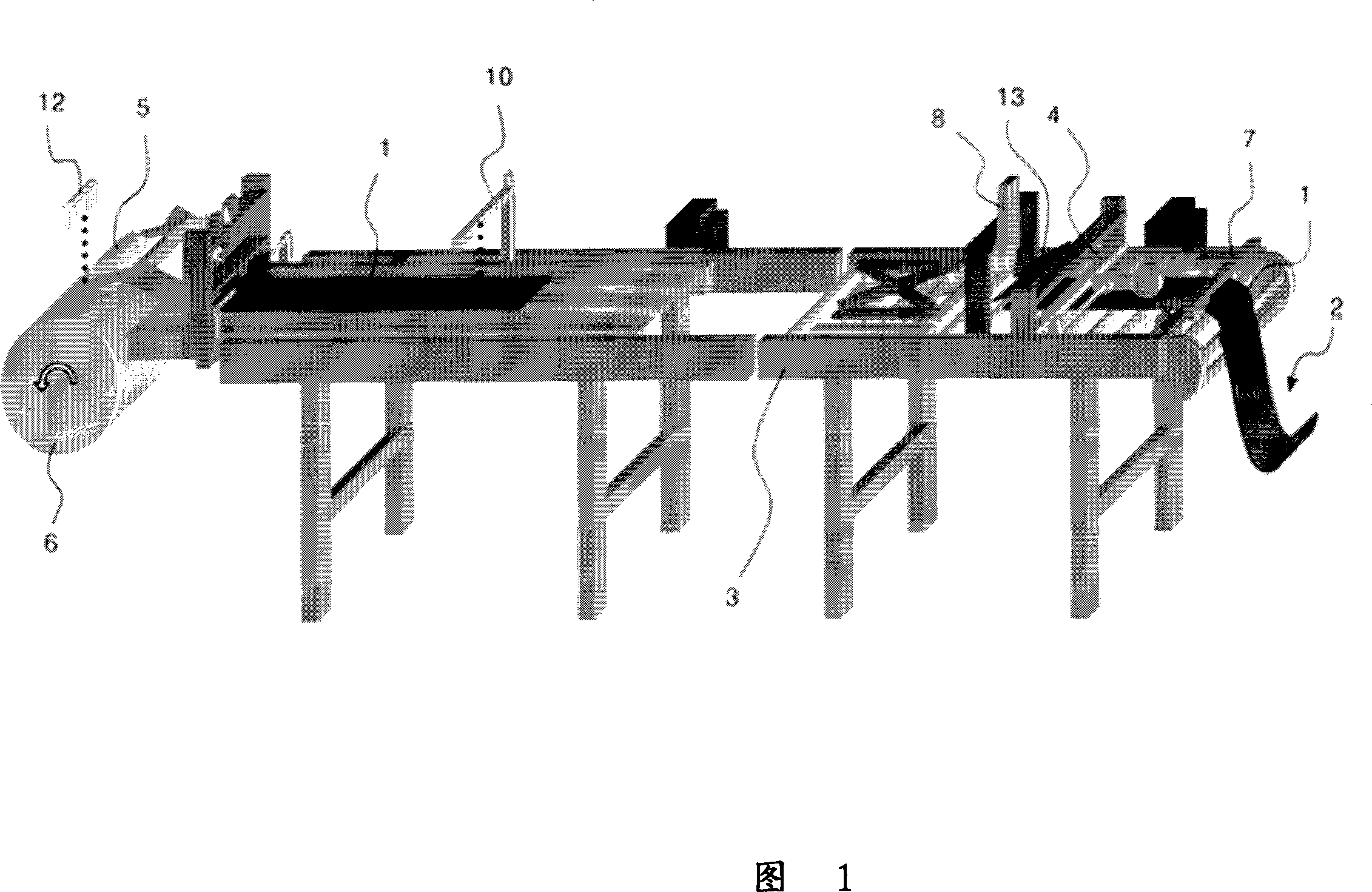

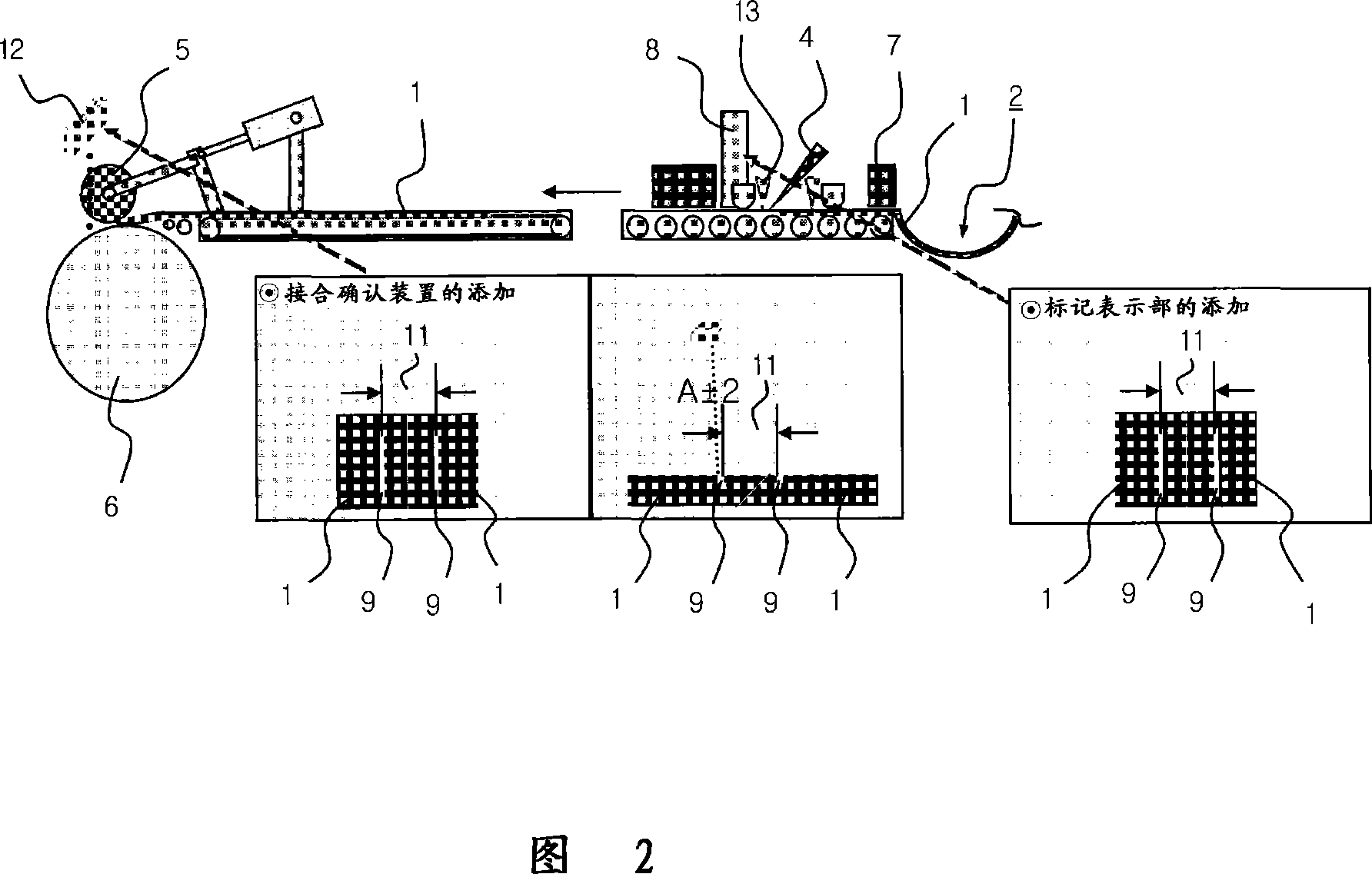

[0013] FIG. 1 is a schematic diagram showing the overall configuration of an automatic tread joining device according to the present invention, and FIG. 2 is a schematic explanatory view illustrating tread length measurement and joining operations according to the present invention.

[0014] The present invention is constituted as a tread jointing device: the tread 1 rolled on the trolley is thrown into the conveying conveyor belt 3 through the loop 2, and after being cut at a predetermined length by the cutting part 4, it is rolled up by the squeeze roller 5. On the forming belt cylinder 6 and joining, in which the width guide part 7 for guiding the initial width of the tread 1 is provided on the front side of the above-mentioned cut part 4, and the marking part is provided on the rear side of the above-mentioned cut part 4, respectively. 8. A length measuring part 10 is provided between the above-mentioned marking part 8 and the forming belt cylinder. The length measuring par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com