Labor-saving perforating machine

A punching machine and punching technology, applied in metal processing and other directions, can solve the problems of difficult handle pressing, low production efficiency and high production cost, and achieve the effects of easy assembly, high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

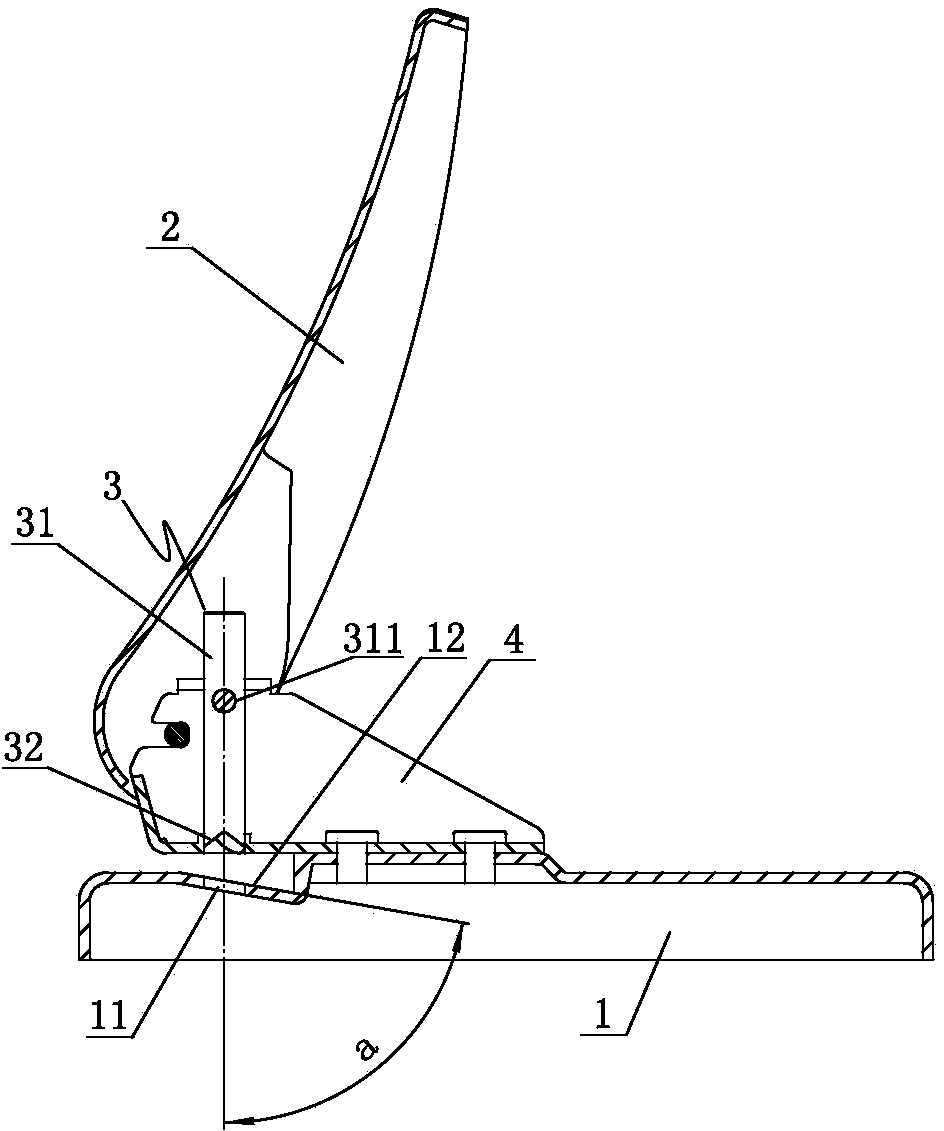

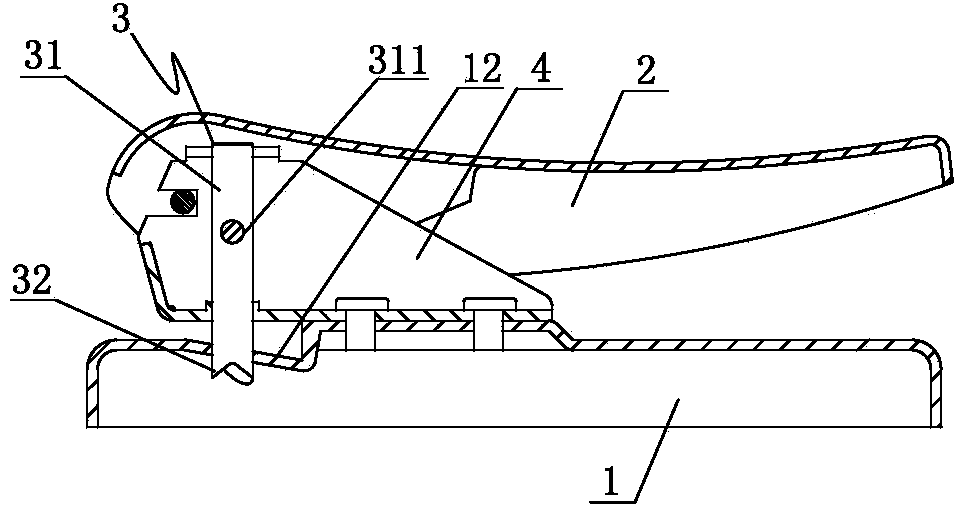

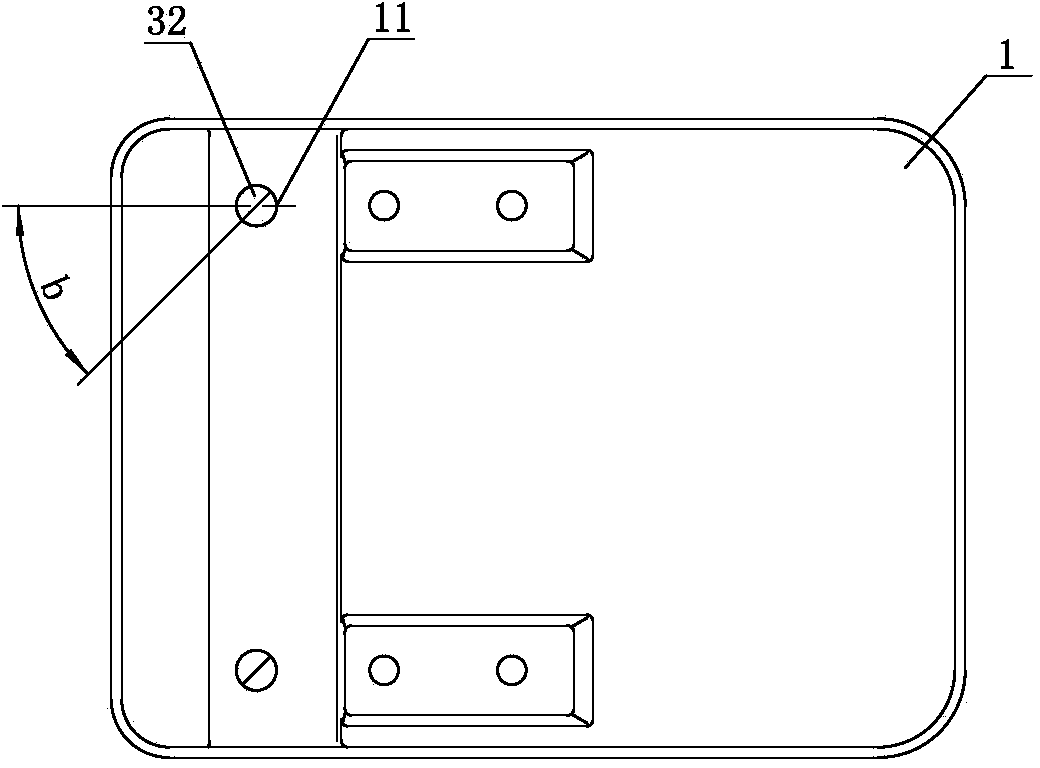

[0016] like figure 1 , figure 2 and image 3 A labor-saving punching machine is shown, which includes a base 1, a handle 2, a cutter 3 and a bracket 4 (of course, it also includes other parts, but since it does not involve the invention of the present invention, it will not be repeated here), The bracket 4 is fixedly connected to the base 1, the handle 2 is hinged to the bracket 4, the cutter 3 is slidably connected to the bracket 4, and the base 1 is provided with punching holes 11 corresponding to the cutter 3 one by one. , the base 1 directly below the cutter 3 is provided with a bevel 12, and the angle a between the axis of the cutter 3 and the bevel 12 is less than 90° (83° in this example, it can also be 80°, 81°, 85° or 86°, etc., that is, the angle between the slope and the horizontal plane is 7°, 10°, 9°, 5° or 4°), the punching ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com