Ink-jet printing head, liquid spraying device and its pressure modulating unit and regulating method

A technology of modulation unit and adjustment method, applied in printing and other directions, can solve the problems of small pressure control range, easy material deterioration of air bags, long assembly time, etc., and achieves the effects of high reliability, easy assembly and few components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

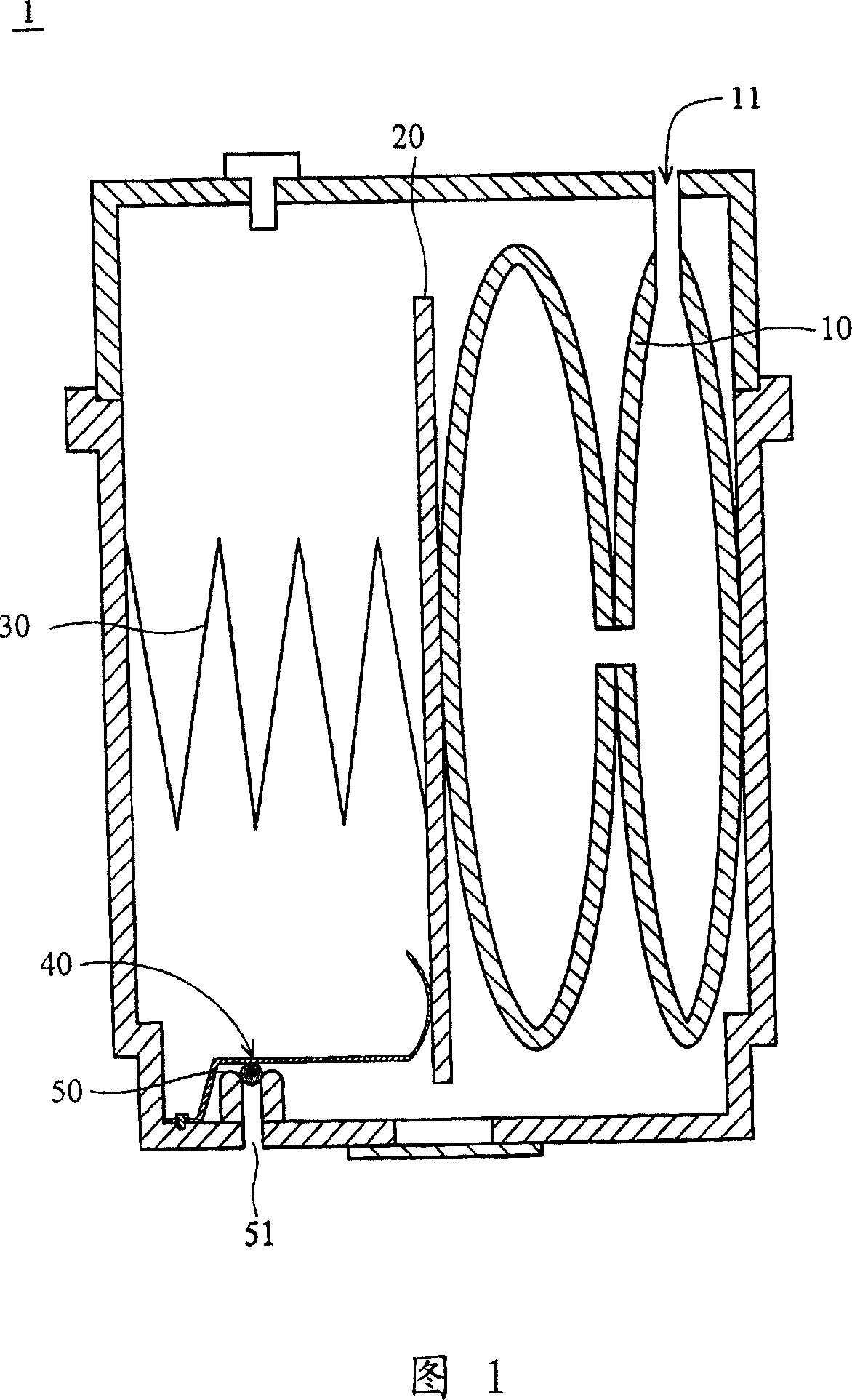

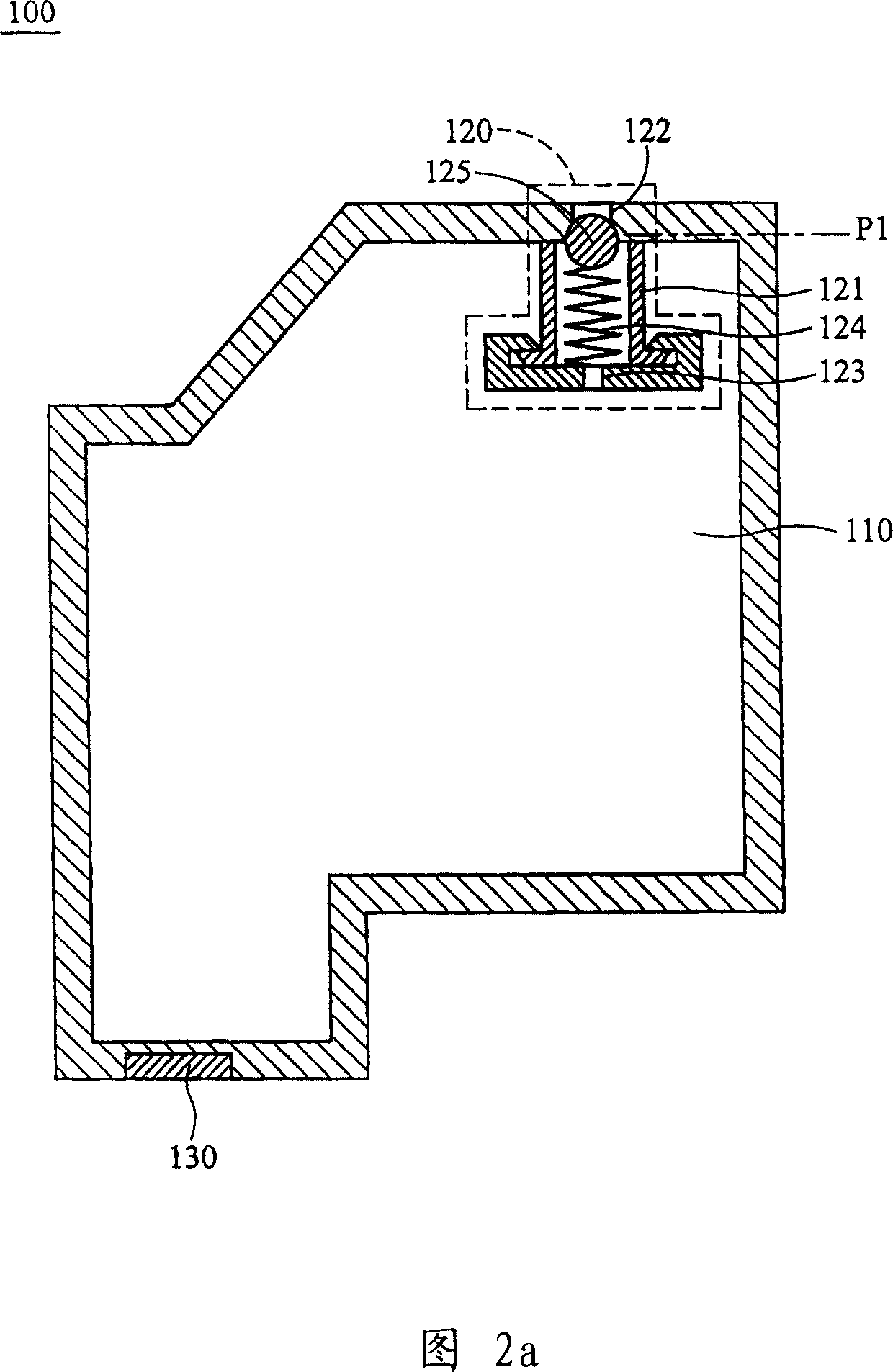

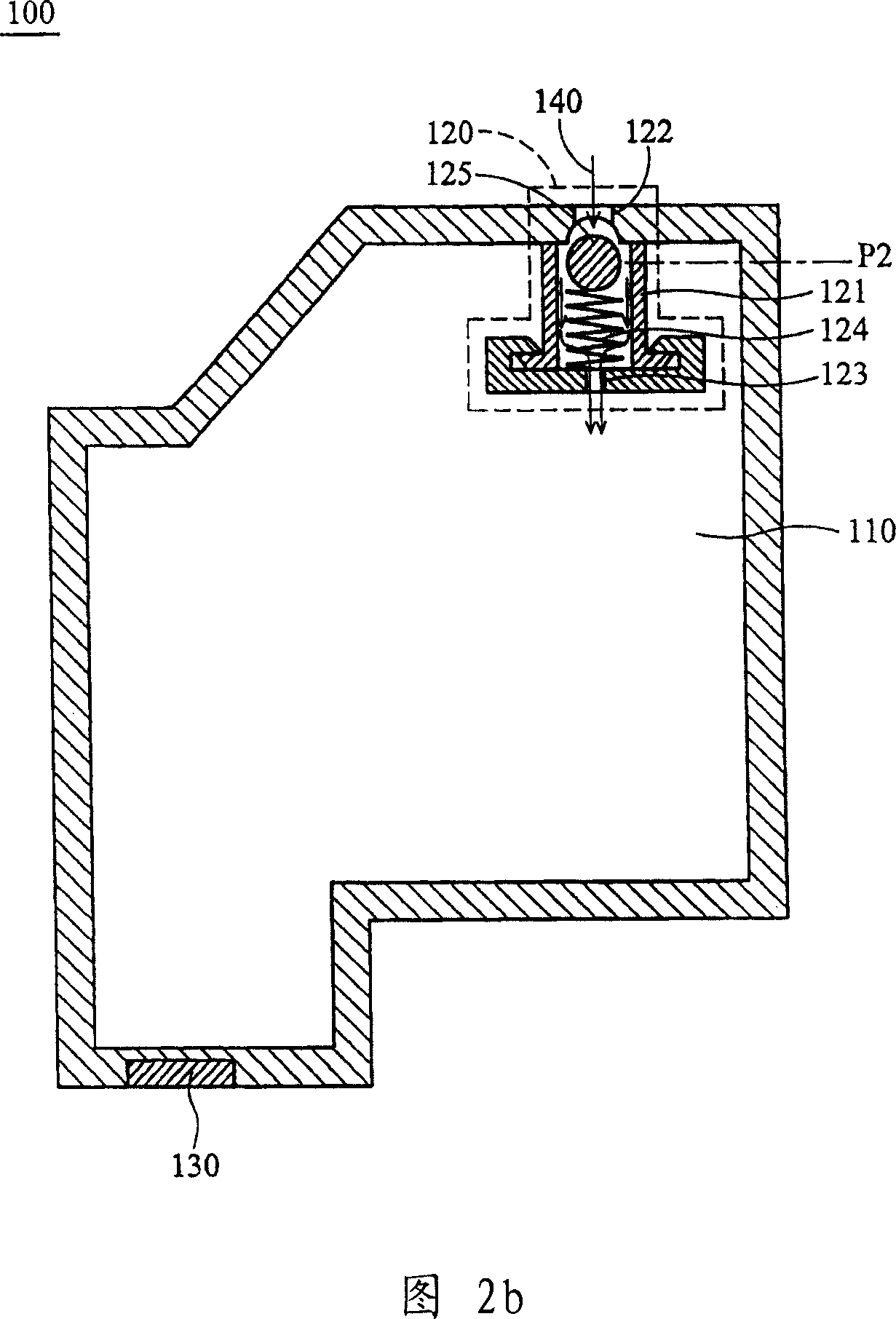

[0051] Referring to FIG. 2 a and FIG. 2 b , it shows the inkjet print head 100 according to the first embodiment of the present invention, including a cavity 110 , a pressure modulation unit 120 and a nozzle 130 . The pressure modulation unit 120 is disposed in the cavity 110 and communicates with the cavity 110 . The pressure modulation unit 120 includes a housing 121 , an air inlet 122 , an air outlet 123 , an elastic mechanism 124 and a sealing block 125 . The intake port 122 is opened on the surface of the cavity 110 . The air outlet port 123 is opened on the surface of the casing 121 . The sealing block 125 is connected to the elastic mechanism 124 . The elastic mechanism 124 abuts against the casing 121 . The elastic mechanism 124 moves the sealing block 125 between a first position P1 (refer to FIG. 2 a ) and a second position P2 (refer to FIG. 2 b ) through elastic force. Referring to FIG. 2 a , when the sealing block 125 is located at the first position P1 , the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com