Cover body for car roof fillet and its mounting structure

A technology for mounting structures and moldings, which is applied to vehicle components, transportation and packaging, and additional accessories. It can solve the problem of many assembly hours and achieve the effects of improving installation performance and suppressing dimensional errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, embodiments of the roof molding cover body and its mounting structure according to the present invention will be described with reference to the drawings.

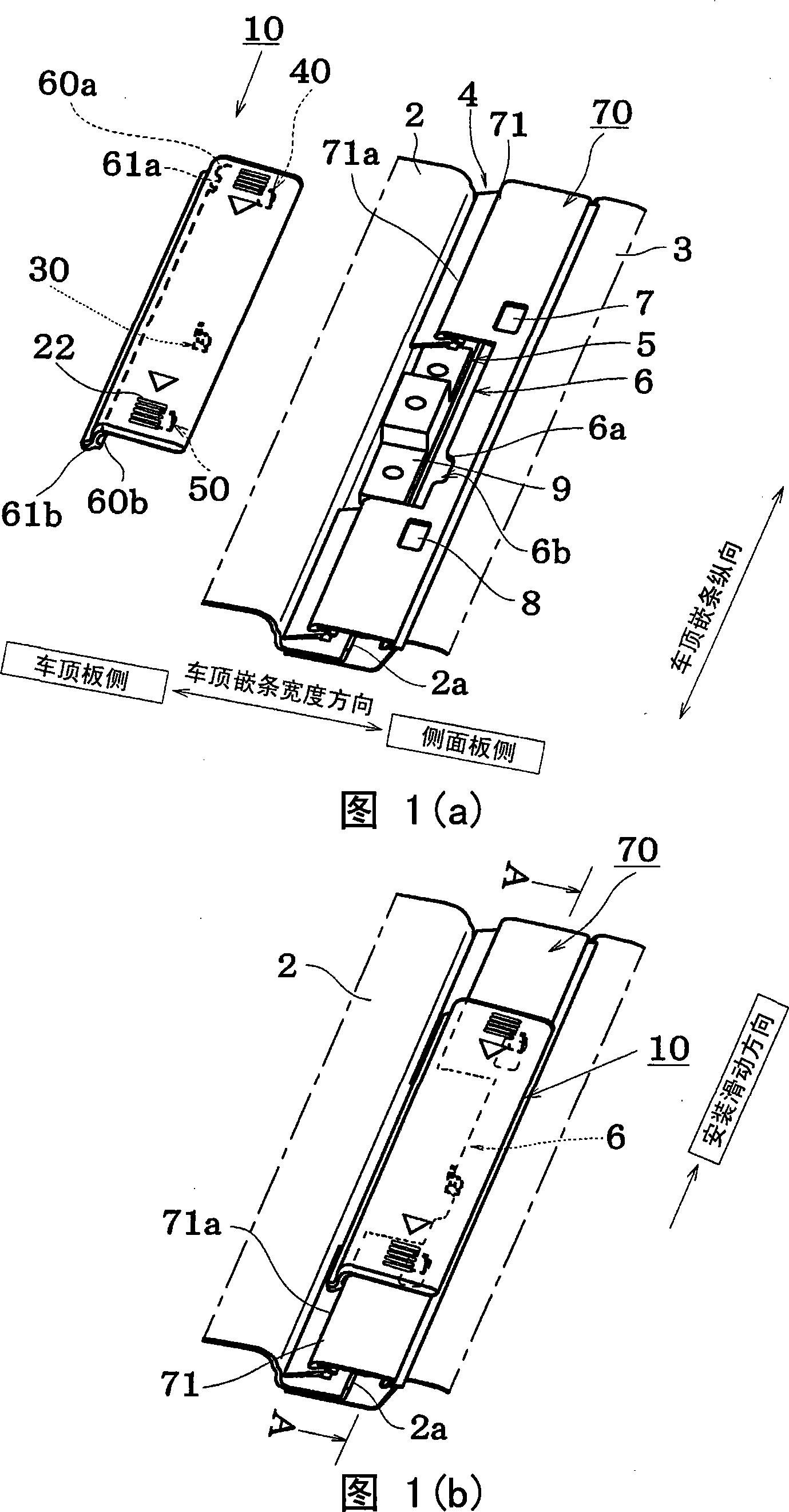

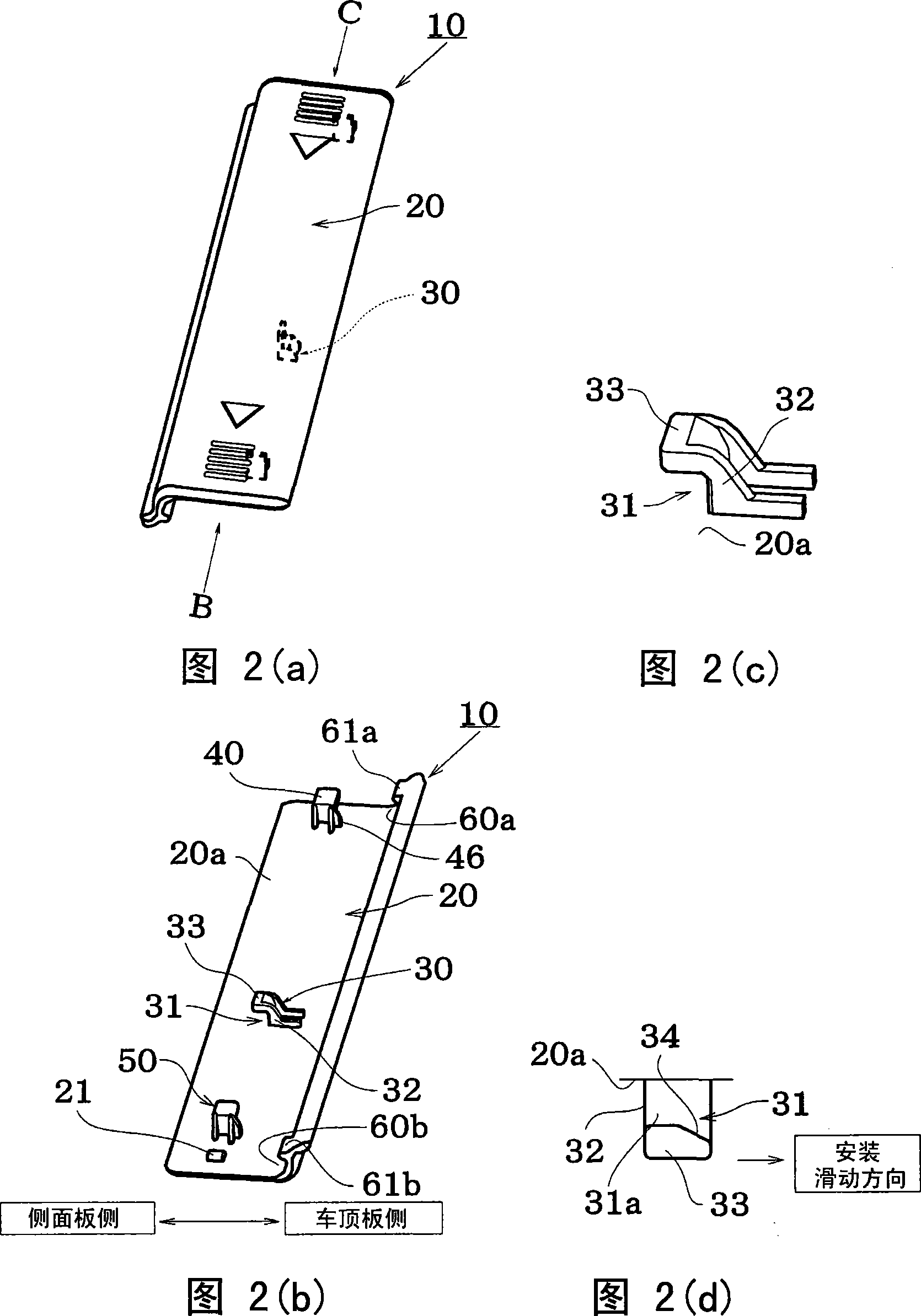

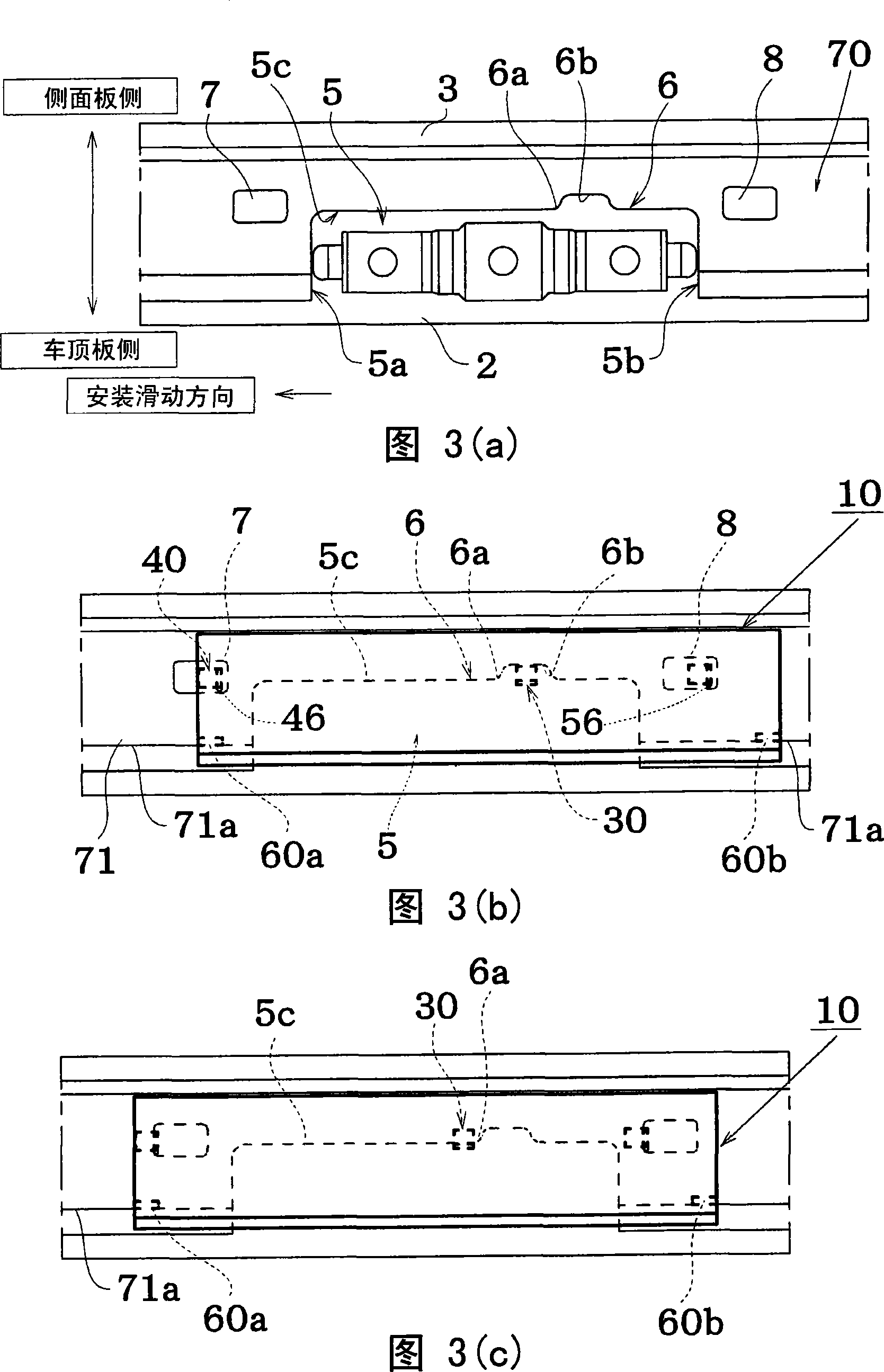

[0054] 1 to 7 show a first embodiment of a roof molding cover and its attachment structure of the present invention.

[0055] FIG. 1 shows the vicinity of a fitting 9 attached to a groove portion 4 formed along a connection portion of a roof panel 2 and a side panel 3 of a vehicle. A support member (bracket) such as a roof rack not shown in the figure is attached to the mounting bracket 9 . FIG. 1( a) shows a state where the roof molding 10 of the present invention is removed from the opening 5 of the roof molding 70, and FIG. The state of opening portion 5, Fig. 2 (a) is the outside perspective view of cover body 10, Fig. 2 (b) is the inside perspective view of cover body 10, Fig. 2 (c) is the engagement portion 30 of Fig. 2 (b) As an enlarged perspective view, FIG. 2( d ) is an enlarged front view o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com