Pressure state display device

A state display and pressure technology, applied in the direction of measuring devices, measuring fluid pressure, piston type fluid pressure measurement, etc., can solve the problems of poor identification, inability to judge whether the pressurized fluid is supplied, and installation of multiple pipe joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, the present invention will be described in detail according to the embodiments of the present invention. In different embodiments, the same reference numerals are used to denote the same components.

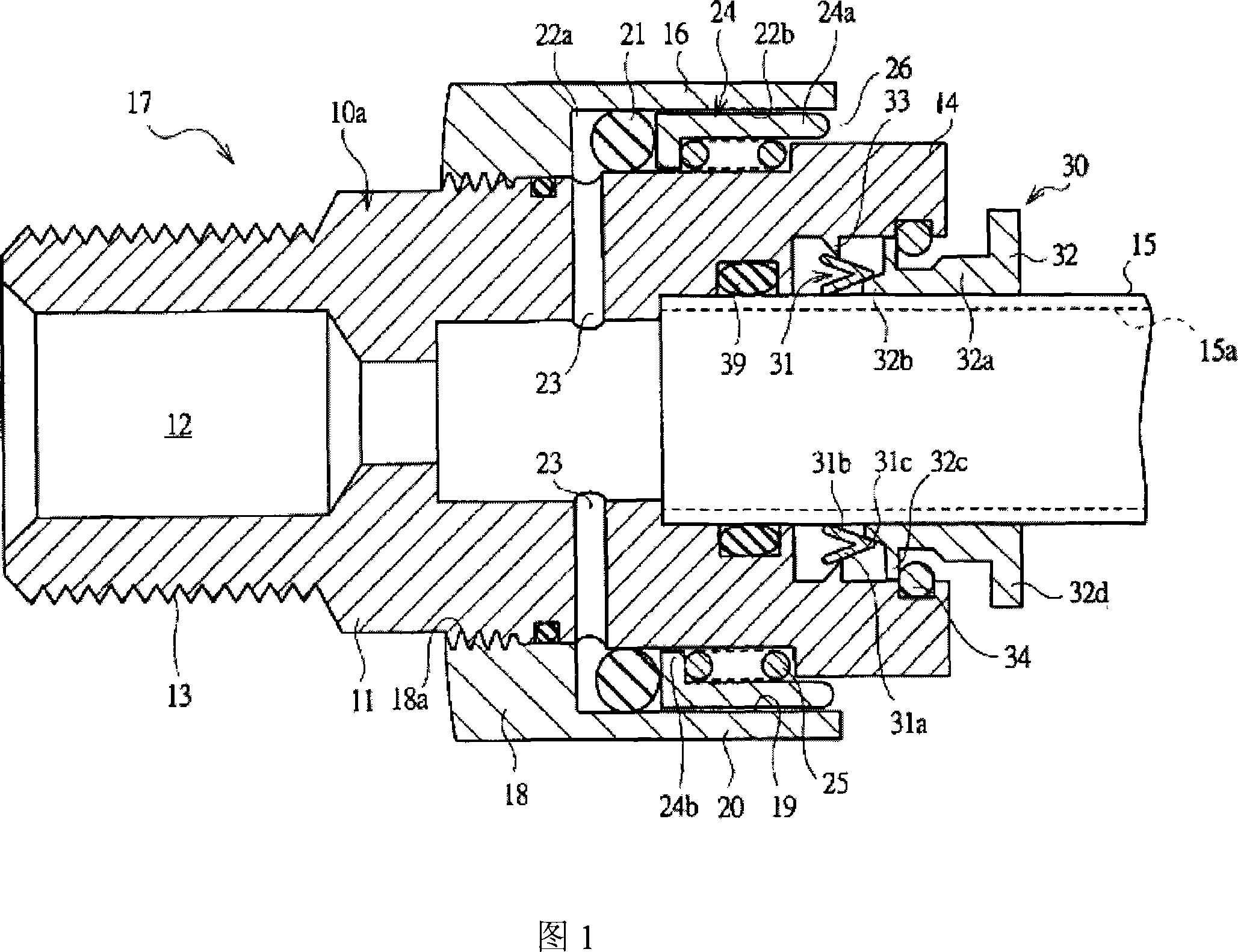

[0045] The pipe joint 10a shown in FIG. 1 is of a linear type, and is installed on a control mechanism or a fluid pressure working mechanism that constitutes a fluid pressure circuit, and is used to guide compressed air. The pipe joint 10 a has a stepped cylindrical joint body 11, and a fluid flow path 12 for guiding compressed air is formed through the inside of the joint body 11. The base end side of the joint body 11 is provided with an external thread 13 for attaching the pipe joint 10a to a control mechanism or a fluid pressure operating mechanism, etc., and the fluid tube 15 is detachably connected to a connecting end 14 on the front end side. on. The fluid tube 15 is formed of a flexible material composed of soft resin such as nylon and urethane. If the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com