Vacuum cleaner electric motor air-out door bridging structure

A technology for air suction vents and vacuum cleaners, which is applied to vacuum cleaners, cleaning equipment, household appliances, etc. It can solve the problems of interfering with the vortex airflow suction effect and reduce the suction rate of the suction port, so as to improve the suction rate and facilitate the continuation of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

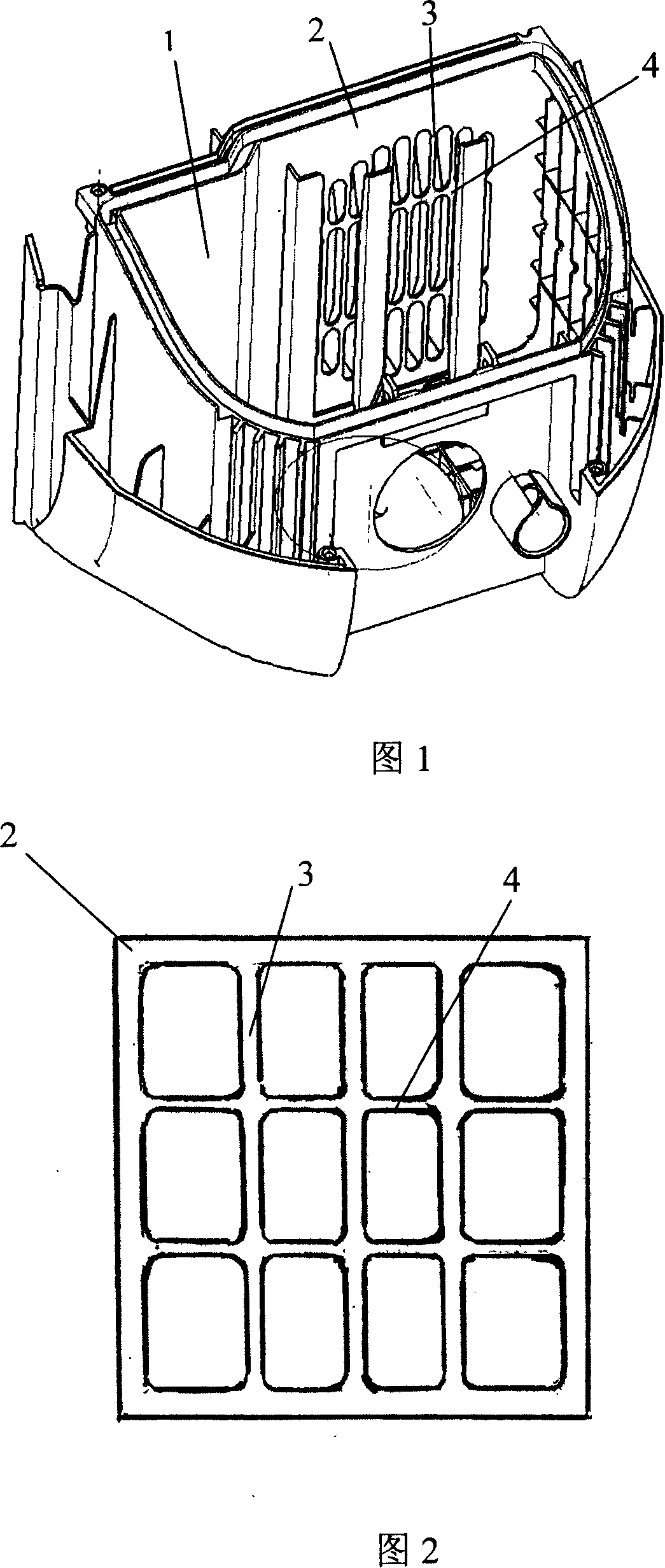

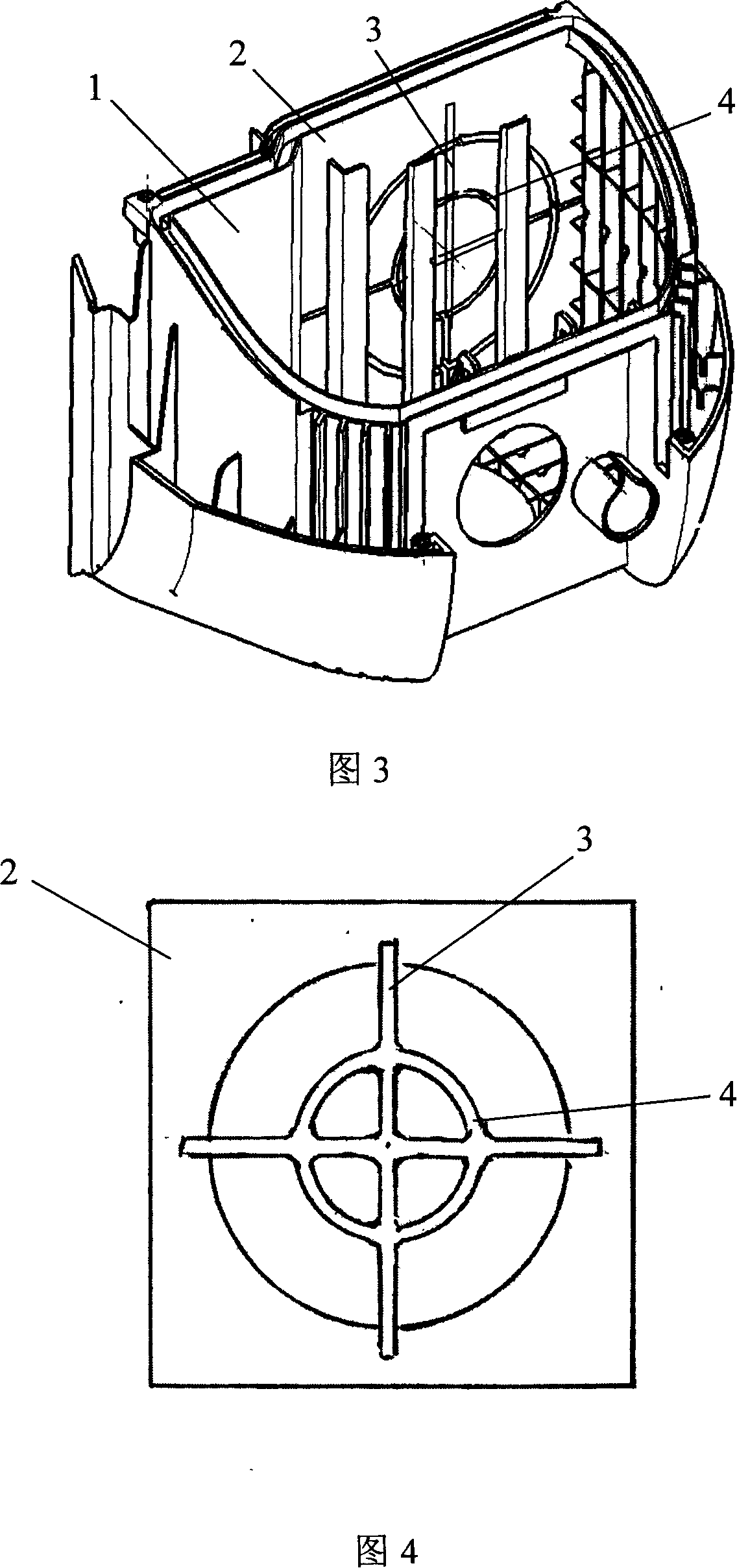

[0020] Fig. 3 is a schematic diagram of the position of the joist of the motor air outlet according to the embodiment of the present invention; Fig. 4 is a schematic diagram of the joist of the motor air outlet according to the embodiment of the present invention.

[0021] Referring to accompanying drawing 3: a kind of joist structure of vacuum cleaner motor suction outlet, comprises the joist frame 2 that forms shape, the joist rib 3 that supports joist frame and the connecting rib 4 that connects joist rib; joist frame 2 is hollow circular Forming, the joist ribs 3 are formed radially toward the circular edge of the joist frame 2 with the circular center point of the joist frame 2 as the center.

[0022] Referring to accompanying drawing 4:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com