Production monitoring system and method thereof

A technology of monitoring system and production equipment, applied in general control system, control/regulation system, registration/instruction of machine production, etc., can solve the problem of inability to obtain robot attribute data, peripheral machine tool motion status, robot performance impact, and inability to know the robot in time. Work status, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

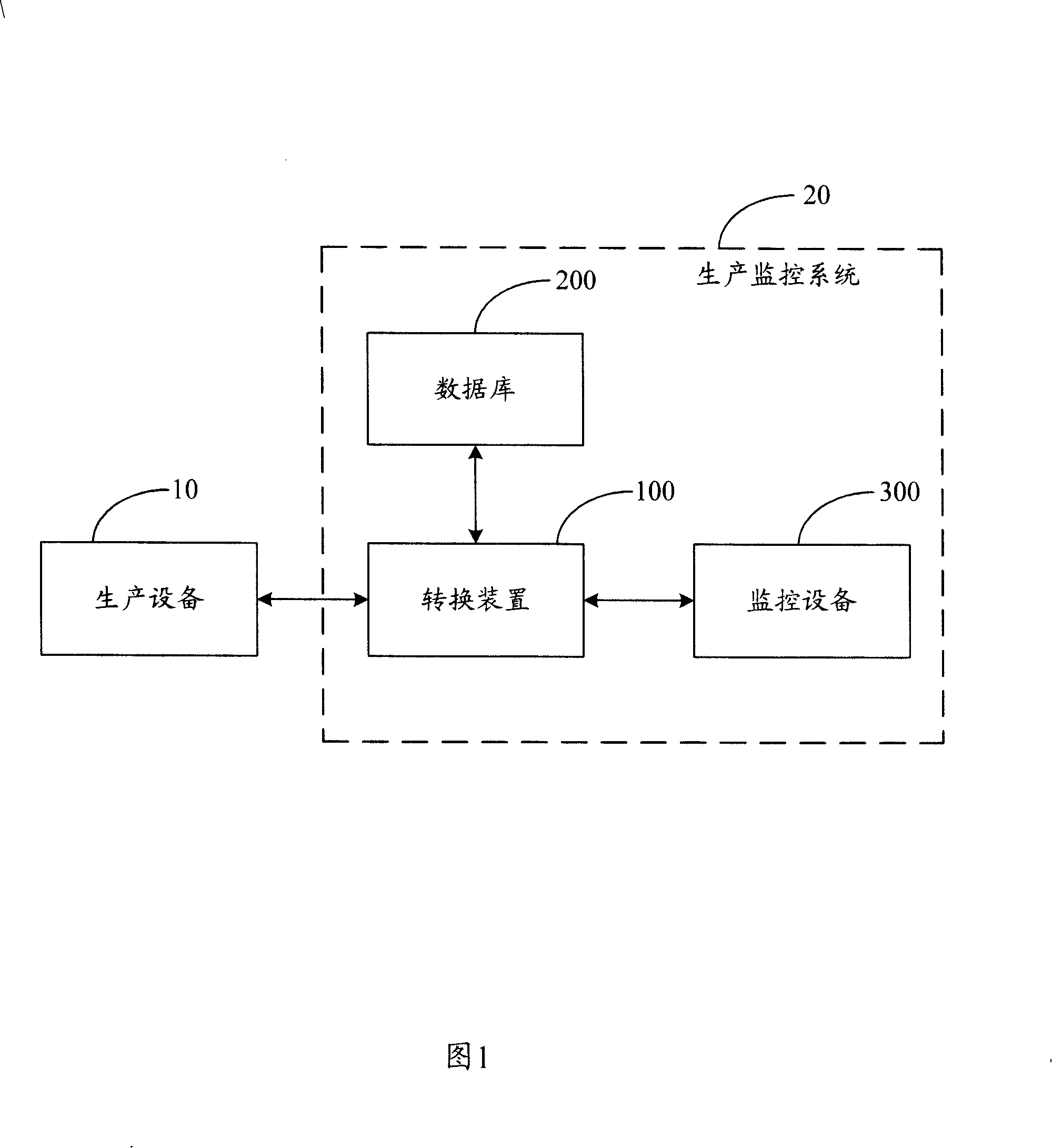

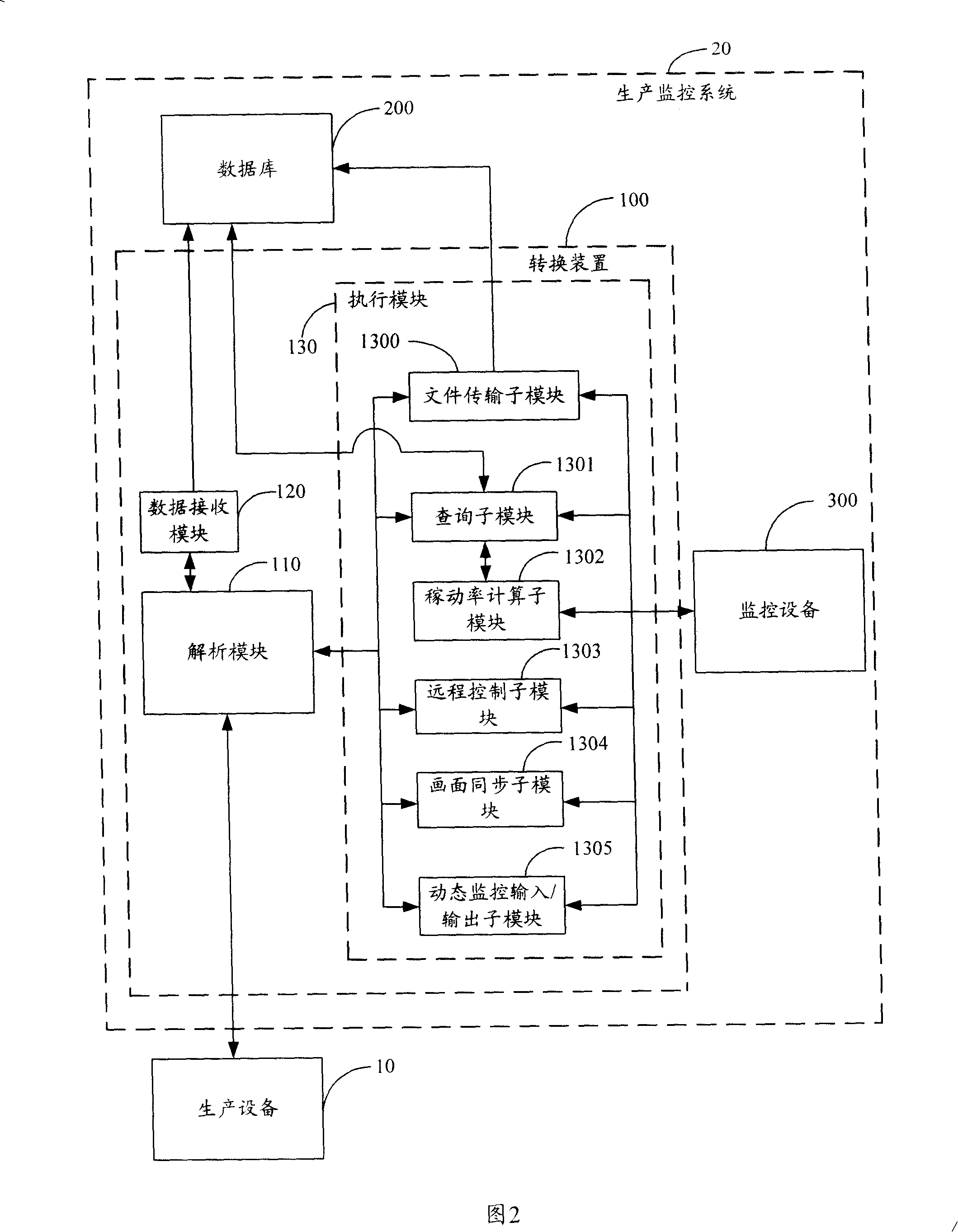

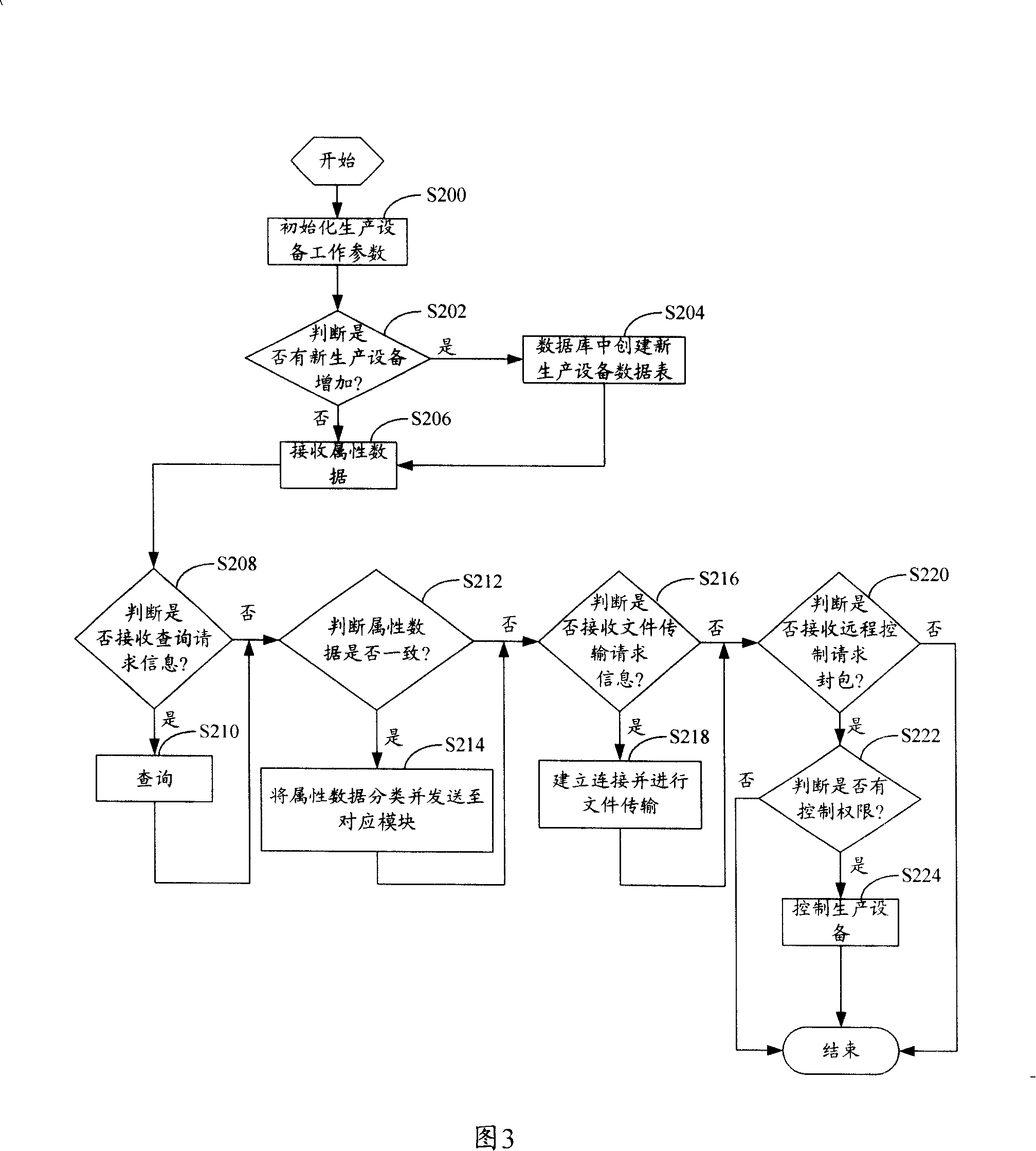

[0013] Please refer to FIG. 1 , which is an application environment diagram of the production monitoring system 20 in the embodiment of the present invention. In this embodiment, the production equipment 10 communicates with the production monitoring system 20 . In this embodiment, the production equipment 10 includes several robots (not shown) and several machine tools (not shown) connected thereto, and the robots and the machine tools jointly produce. The production monitoring system 20 is used to send monitoring information and receive attribute data of the production equipment 10 , including a conversion device 100 , a database 200 and a monitoring equipment 300 . In this embodiment, the monitoring equipment 300 is the monitoring computer of the operator, and the conversion device 100 is respectively connected to the database 200, the monitoring equipment 300 and the production equipment 10 through communication, and is used to convert the attribute data of the production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com