Objective lens actuator, diffractive optical element, and optical pickup device

A technology of diffracted light and adjuster, applied in optical components, optics, optical recording heads, etc., can solve the problems of increasing the size of the movable housing, increasing the mass of the balance weight, and reducing the high-order resonance frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

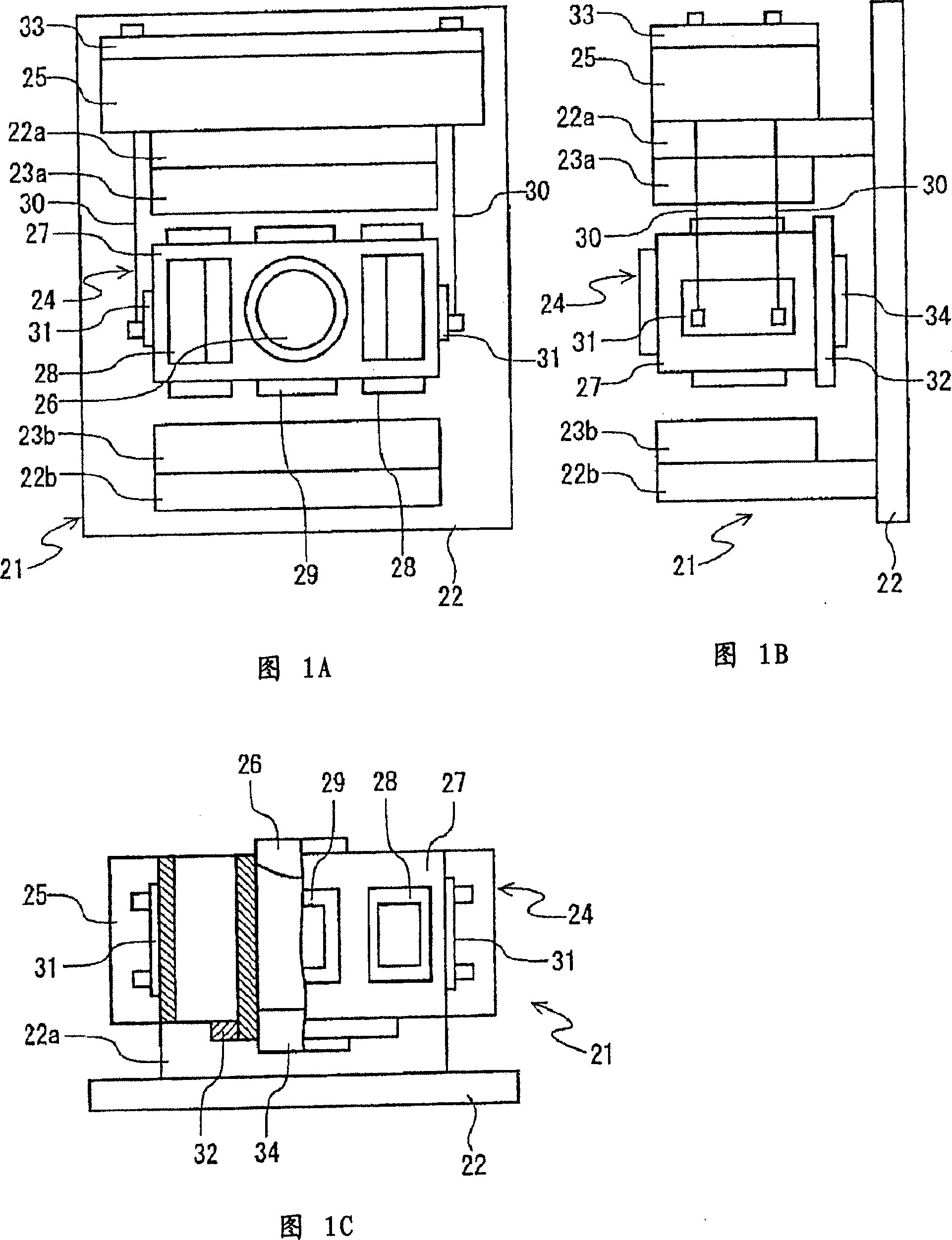

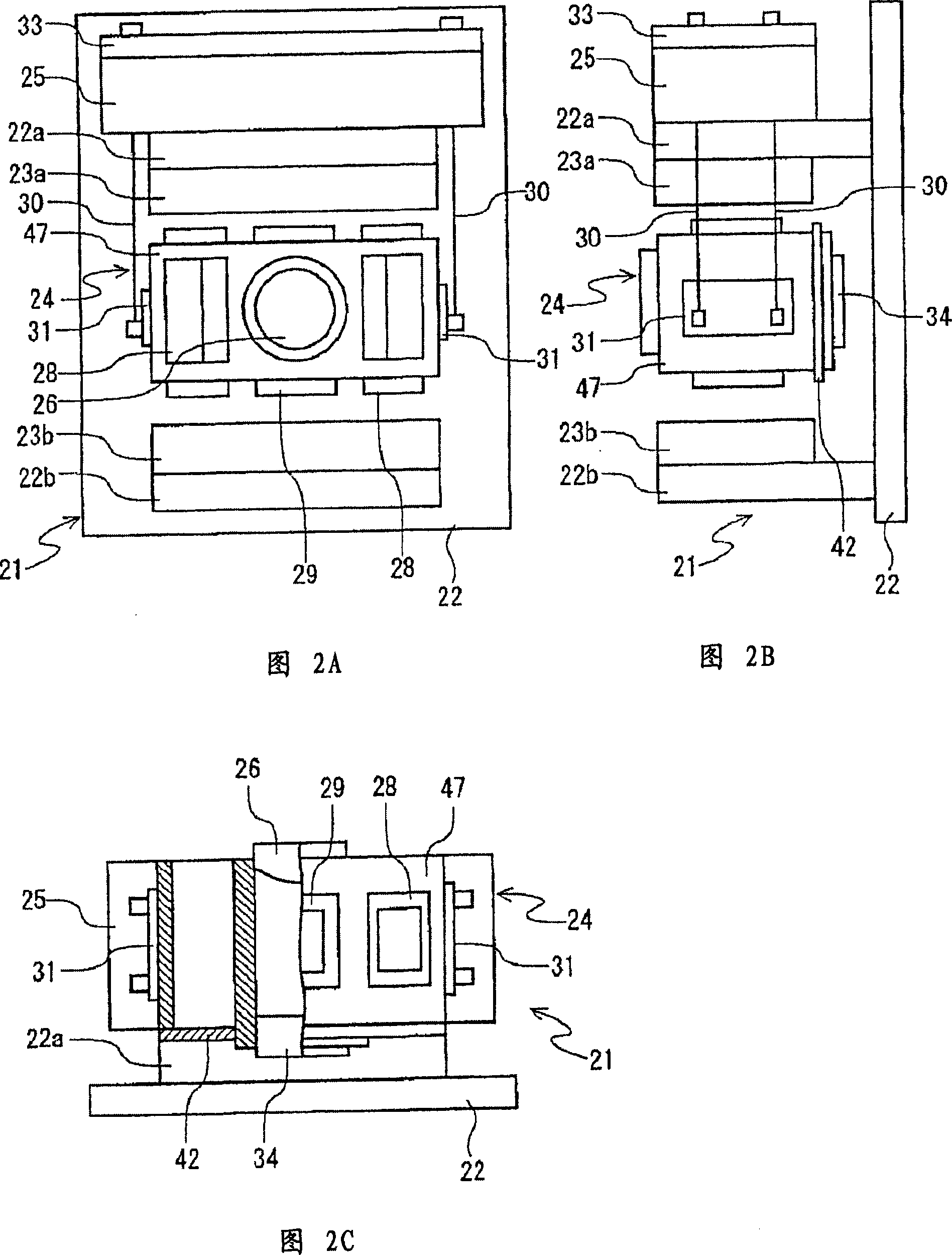

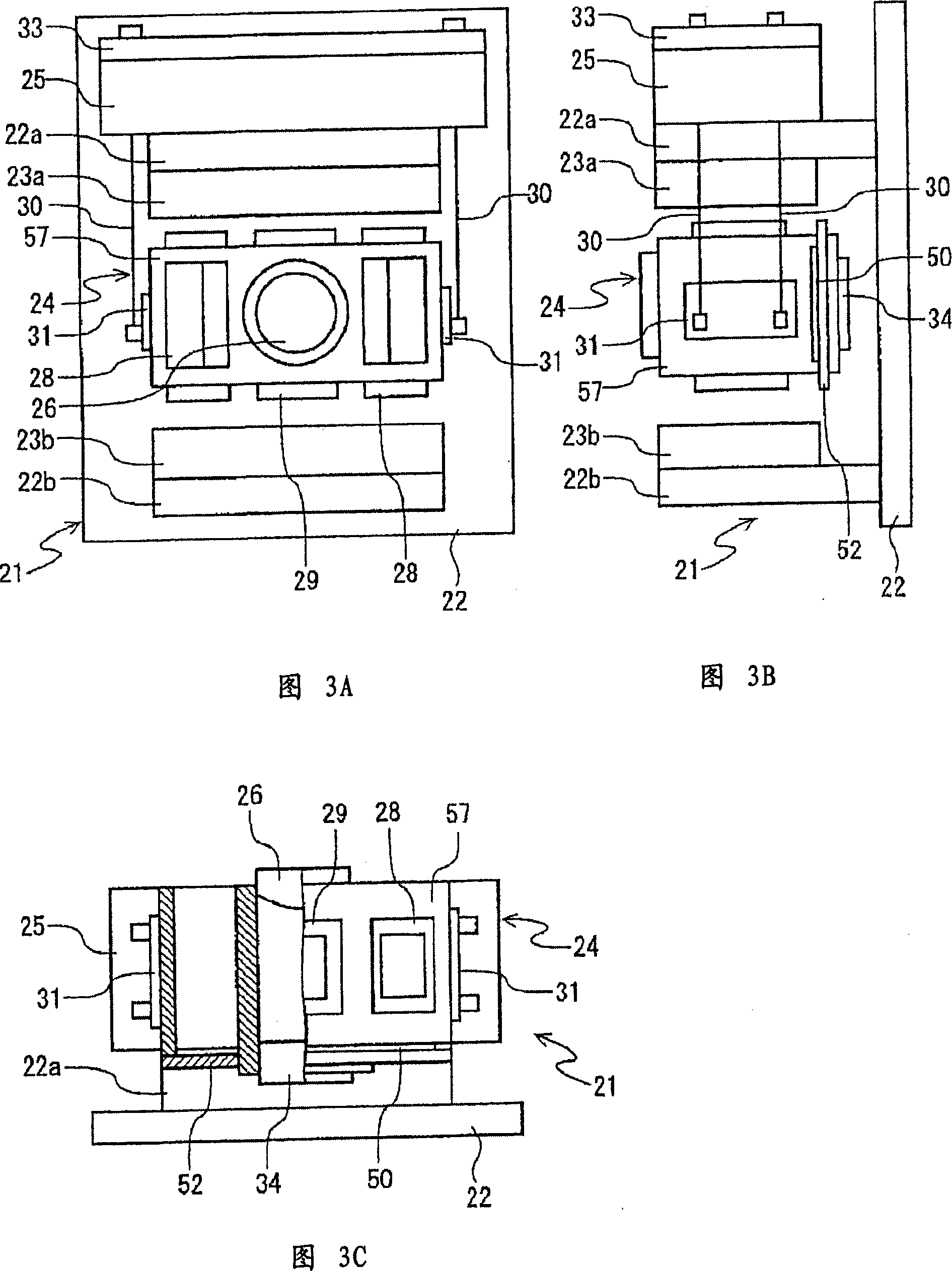

[0086] Exemplary embodiments of the present invention are described in detail below with reference to the accompanying drawings. Like reference numerals designate corresponding elements throughout the figures.

[0087] Fig. 1A is a front view of an objective lens adjuster according to a first embodiment of the present invention. Fig. 1B is a side view of the objective lens adjuster shown in Fig. 1A. Fig. 1C is a bottom view of the objective lens adjuster shown in Fig. 1A. In FIG. 1A, the vertical direction of the paper surface is the tangential direction on the optical disk, the direction perpendicular to the paper surface is the focus, and the horizontal direction of the paper surface is the radial direction (tracking direction). In the following description, both the vertical direction and the horizontal direction are based on FIG. 1A.

[0088] The objective lens adjuster includes a stator unit 21 mounted on the optical information recording / reproducing device. The stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com