Stibium elementarysubstance for accelerating form of type A plumbago in cylinder cover

A cylinder liner, the application of antimony element technology, applied in the field of A-type graphite formation, can solve the problems of loose organization, long graphite length, low mechanical properties and so on

Inactive Publication Date: 2008-04-02

韦斌

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Traditional low-alloy cast iron and alloy cast iron cylinder liners, the metallographic structure is difficult to achieve large-area A-type graphite, the length of graphite is long, the grain is coarse, the structure is loose, the mechanical properties are low, and after a period of use, the wear of the inner hole increases , There is a large gap between the cylinder wall and the piston ring, which causes the engine to increase the exhaust volume, reduce the power, increase the oil consumption, and shorten the service life of the engine.

In severe cases, accidents such as cylinder pulling and platform breakage may also occur

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

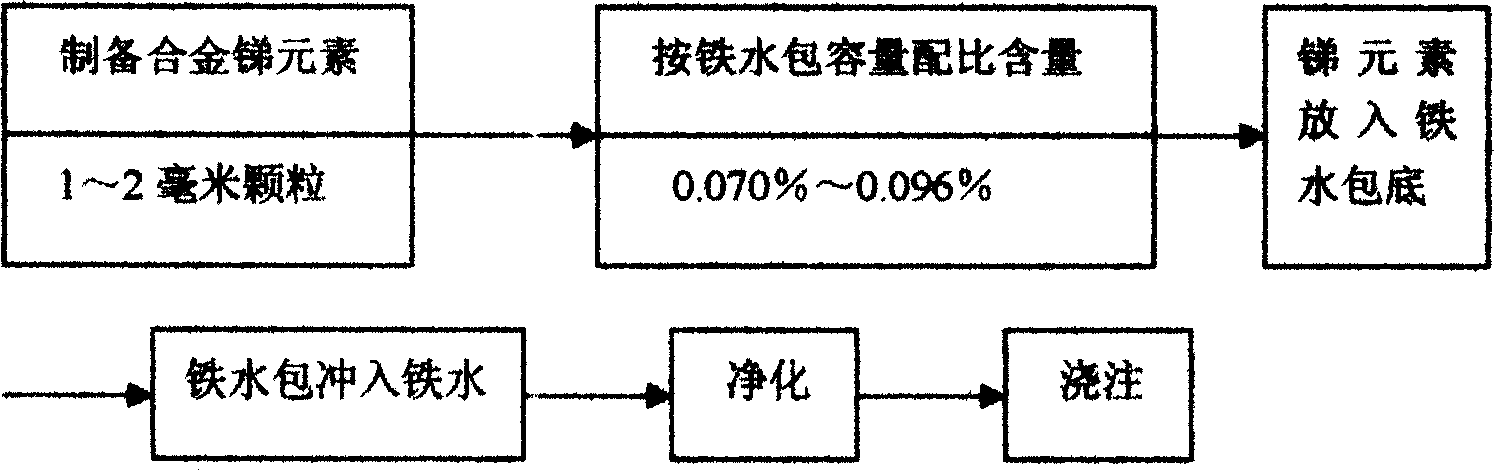

[0010] 1. Make antimony into 1-2 mm fine particles;

[0011] 2. The content of antimony (0.070%-0.096%) according to the ratio of the volume of molten iron in operation;

[0012] 3. Put the antimony in the bag;

[0013] 4. Feed molten iron into the running ladle;

[0014] 5. Purify molten iron for 2-3 minutes;

[0015] 6. Pouring.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to a method with adoption of stibium element which improves the formation of A-type graphite, and is suitable for the requirement on the motor cylinder collar, such as high abrasion-proof quality, and long life span. The present invention uses stibium element to make the size of graphite in the metallography of the cylinder collar be diminished significantly, to obtain the shred-like A-type graphite with even distribution. The latent heat of the melting stibium is great (19875.8J / mol), therefore, when the stibium is added, the temperature in the micro area is caused to vary, which increases the quantity of the cores of the graphite. The volume of the added stibium is controlled between 0.070 and 0.096 percent.

Description

Technical field [0001] The invention relates to an antimony element that promotes the formation of A-type graphite in a cylinder liner, which is suitable for the requirements of high wear resistance and long service life of the engine cylinder liner. Background technique [0002] Traditional low-alloy cast iron and alloy cast iron cylinder liners, the metallographic structure is difficult to achieve large-area A-type graphite, the length of graphite is long, the grain is coarse, the structure is loose, the mechanical properties are low, and after a period of use, the wear of the inner hole increases , There is a large gap between the cylinder wall and the piston ring, which causes the engine to increase the exhaust volume, reduce the power, greatly increase the oil consumption, and shorten the service life of the engine. In severe cases, accidents such as cylinder pulling and platform breaking also occur. Contents of the invention [0003] The invention uses the antimony ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C33/08C22C37/00B22D11/108

Inventor 韦斌

Owner 韦斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com