Ultra-fine austempering nodular iron material and preparation method thereof

A technology for austempering and ductile iron, which is used in the preparation of warm quenched ductile iron materials and the field of warm quenched ductile iron materials, can solve the problems of inapplicability, large diameter of graphite balls, and low distribution density of graphite balls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

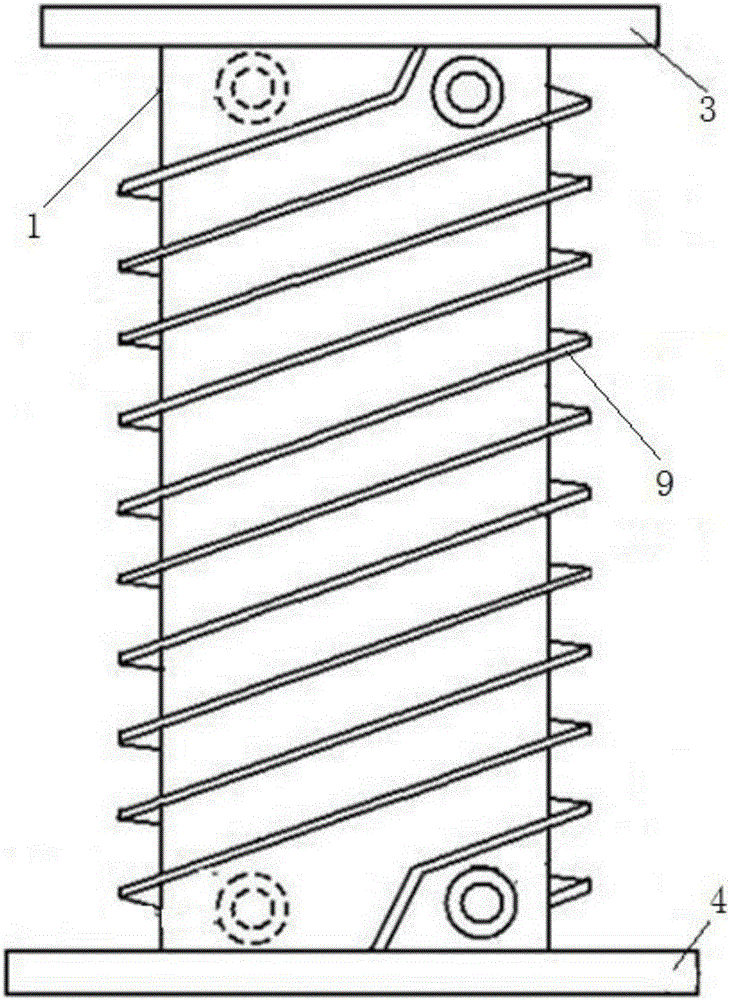

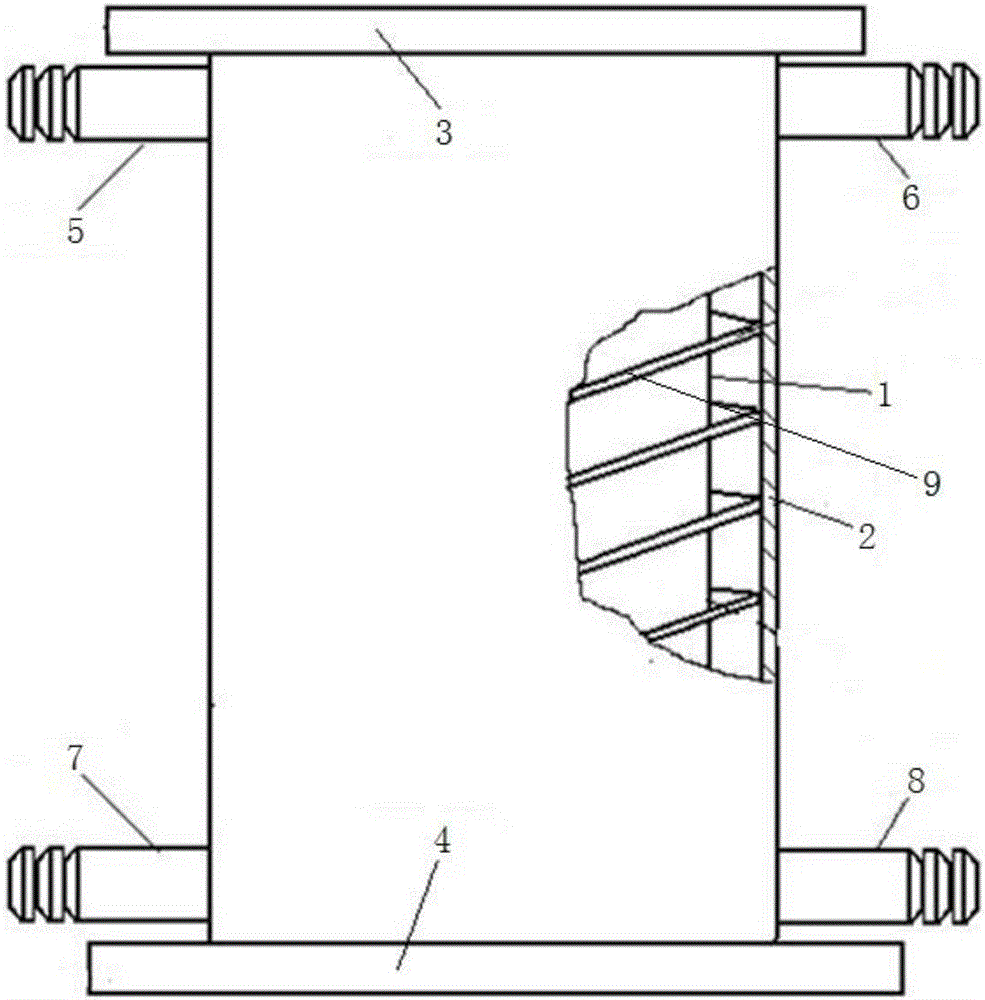

[0044] The present invention also provides a preparation method for the above-mentioned cast iron material, which is described in the patent "Continuous Casting and Forming Equipment for Low Plastic Metal Hollow Profiles" (Patent No.: ZL200710018928.2, Publication No.: 101134231, Publication Date: 2008-03-05) Implementation above, the difference with the original device is that the structure of the crystallizer in the original device is different from that of the crystallizer in the present invention, and the crystallizer in the present invention is a water-cooled crystallizer with double helix two inlets and two outlets, such as Figure 1~2 As shown, its structure is as follows: it includes an inner cylinder 1 and an outer cylinder 2 that are nested with each other. The bottom of the outer cylinder is connected with the lower flange 4, the upper part of the outer cylinder 2 is respectively provided with water inlet I5 and water inlet II6, the lower part of the outer cylinder 2...

Embodiment 1

[0069] Weigh the following components according to mass percentage: C: 3.7%, Si: 1.7%, Mn: 0.4%, Cr: 0.3%, S≤0.05%, P≤0.05%, Fe and other impurities are the balance, the above The sum of the mass percentages of the components is 100%, and the above materials are melted into molten iron, the final silicon content is 2.7%, and the residual magnesium content is 0.04%;

[0070] Using the vertical continuous casting method, the molten iron is drawn into a profile billet by using a double-helix two-inlet and two-outlet water-cooled crystallizer;

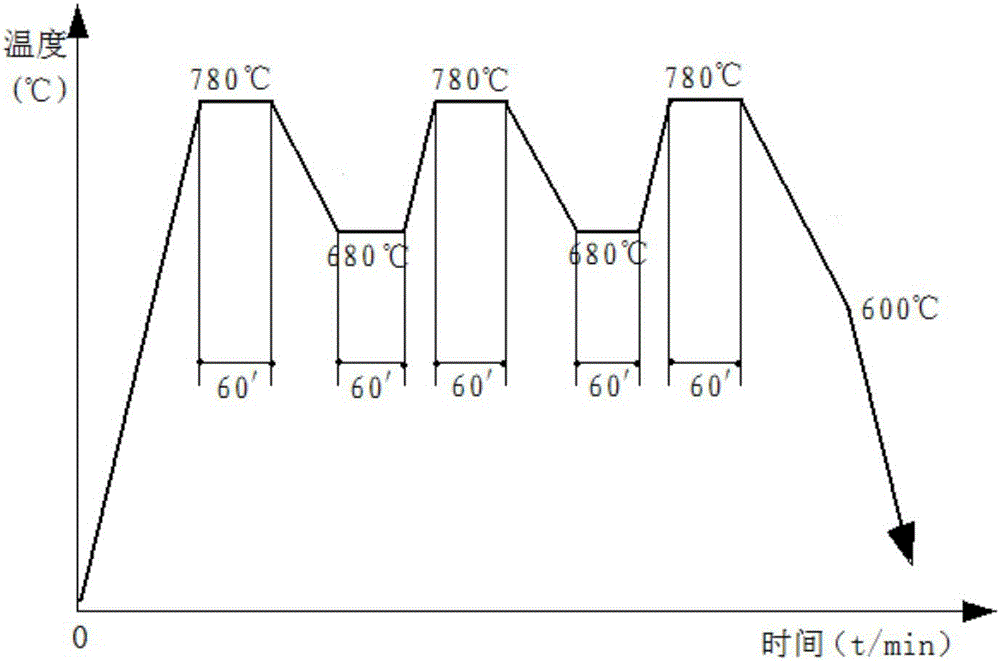

[0071] Conduct metallographic inspection on the original blank of the profile, including: Ⅰ. The spheroidization rate of graphite nodules not greater than 20mm from the surface is ≥ 90%; Density ≥ 550 pieces / mm 2 ;The density of graphite balls in the range of 5-10mm from the surface is ≥450 / mm 2 , the density of graphite balls within 10-15mm from the surface is ≥350 / mm 2 , the density of graphite balls in the range of 15-25mm from the s...

Embodiment 2

[0076] Weigh the following components according to mass percentage: C: 3.6%, Si: 1.5%, Mn: 0.3%, Cr: 0.5%, S≤0.05%, P≤0.05%, Fe and other impurities are the balance, the above The sum of the mass percentages of the components is 100%, and the above materials are melted into molten iron, the final silicon content is 2.8%, and the residual magnesium content is 0.045%;

[0077] Using the vertical continuous casting method, the molten iron is drawn into a profile billet by using a double-helix two-inlet and two-outlet water-cooled crystallizer;

[0078] Conduct metallographic inspection on the original blank of the profile, including: Ⅰ. The spheroidization rate of graphite nodules not greater than 20mm from the surface is ≥ 90%; Density ≥ 550 pieces / mm 2 ;The density of graphite balls in the range of 5-10mm from the surface is ≥450 / mm 2 , the density of graphite balls within 10-15mm from the surface is ≥350 / mm 2 , the density of graphite balls in the range of 15-25mm from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com