Moulded parts made of pmma powder as simple dosing aid in the manufacture of dental prostheses

A monomer and solvent technology, used in dental preparations, prostheses, dentistry, etc., can solve problems such as dental technical work coordination errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

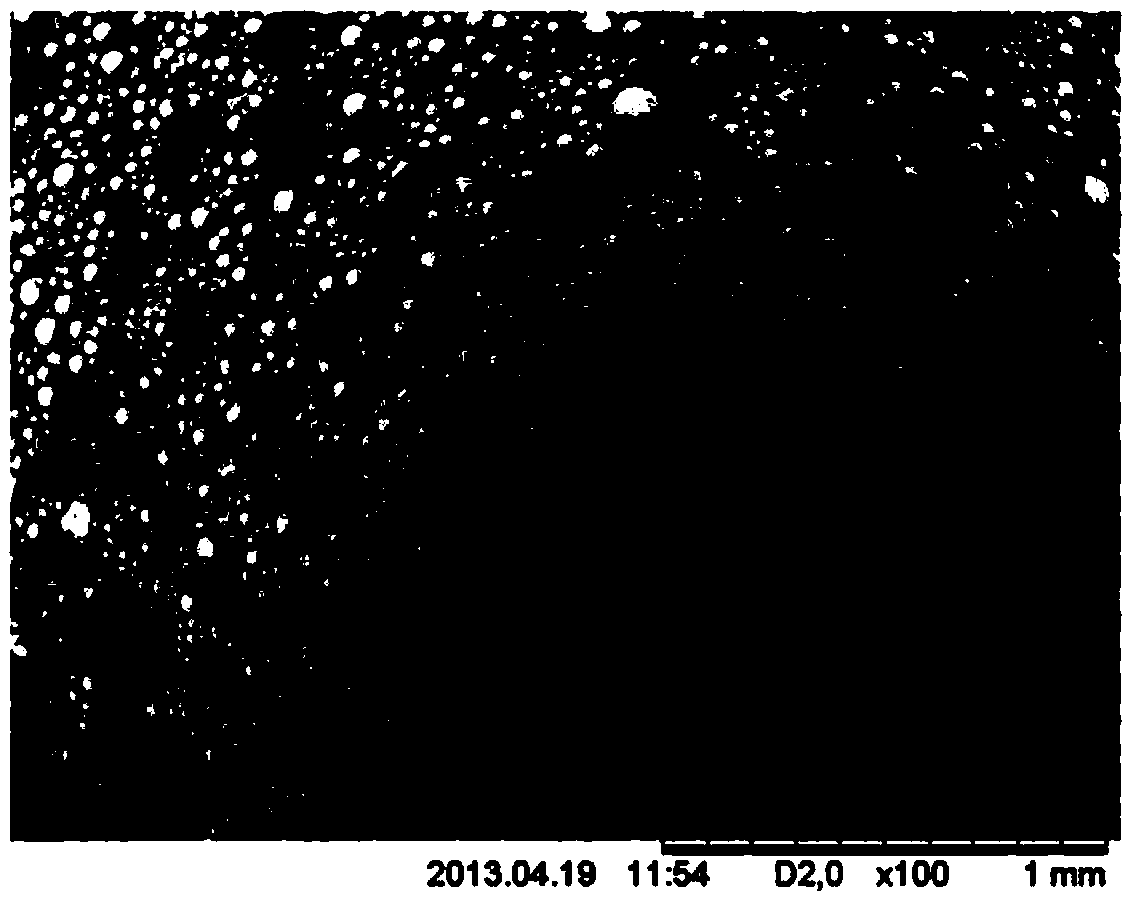

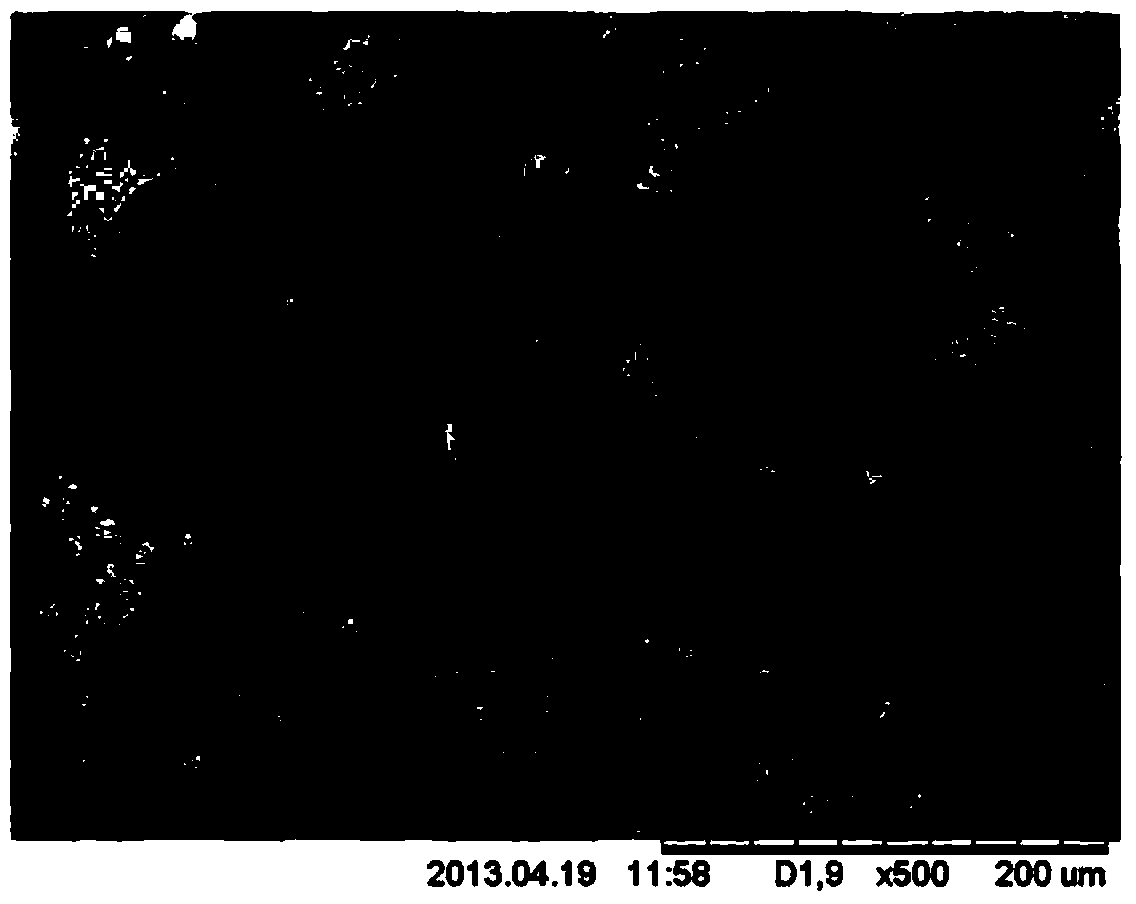

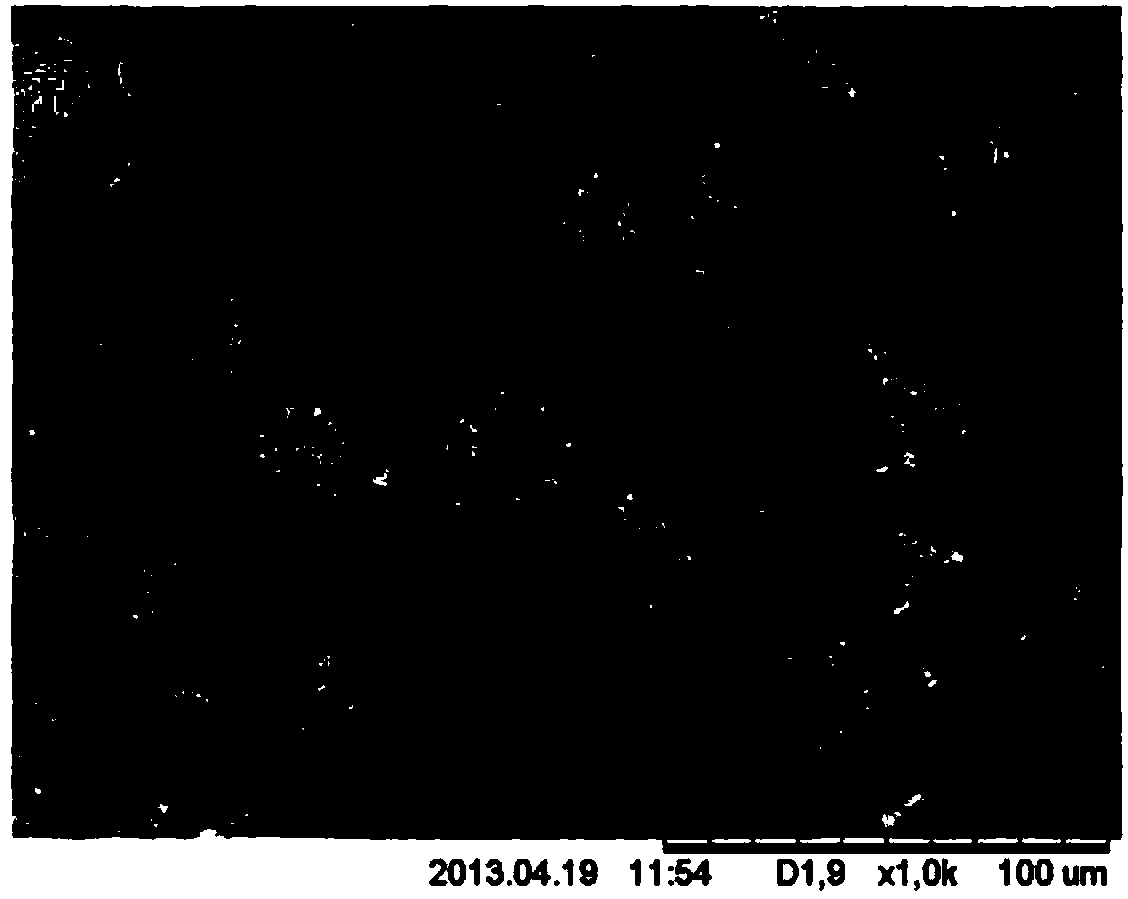

Image

Examples

Embodiment

[0055] Preparation of the mixture: A mixture was prepared from 6.5 ml ethanol and 0.5 ml methyl methacrylate at room temperature.

[0056] Preparation of dispersion: Add 100 g of PMMA powder (such as PalaXpress) to the above mixture at room temperature and stir for about 2 minutes for vigorous mixing.

[0057] Preparation of molded parts: Press the dispersion into a mold with the desired geometry. Alternatively, the suspension can be cast in a three-dimensional mold.

[0058] The mold is usually made of plastic and is stable to the added solvent at the corresponding temperature. The preferred mold is made of deformable or elastic plastic. Particularly suitable are three-dimensional silicone molds, because silicone molds are particularly easy to demold. Generally speaking, a metal mold composed of multiple parts, for example, two parts, or a non-deformable mold composed of multiple parts and made of other materials, can also be used. The molds that can be used are not limited to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com