Test method for simulating oxidation and decarbonization of steel

A test method, a technology for simulating steel, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of high test cost and complicated operation, achieve the effect of enriching research methods, simple test methods, and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

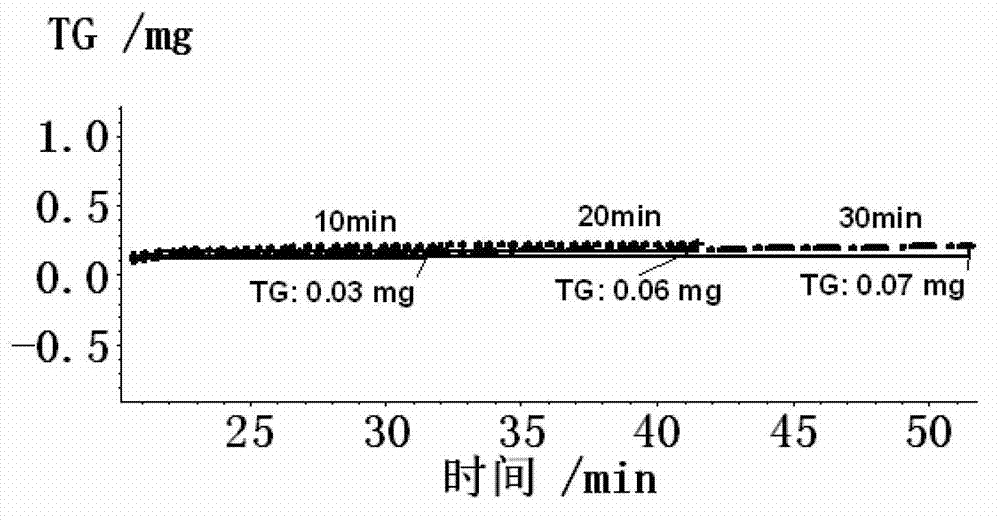

[0021] The present invention heats 55SiCrV spring steel to 850℃, 2% O 2 It is applied in the oxidation decarburization simulation test of different time insulation under the atmosphere, the specific steps are:

[0022] a. Use wire cutting to prepare samples of the same specifications with a diameter of 4.5mm and a height of 6mm;

[0023] b. After rough grinding and fine grinding, the surface of the sample is ultrasonically cleaned. The cleaning agent is 90% ethanol solution;

[0024] c. Place the prepared sample in a dynamic thermogravimetric analyzer with multiple gas paths, first perform 3 vacuuming operations, and then set the test program as follows: under the protection of Ar gas, heat up to 850°C at 40°C / min. , And at 850℃, 2%O 2 Incubate for 10, 20, and 30 minutes in the atmosphere, and then quickly drop to room temperature at 40°C / min under the protection of Ar atmosphere. The total gas flow rate remains unchanged during the entire experiment.

[0025] d. Through the automat...

Embodiment 2

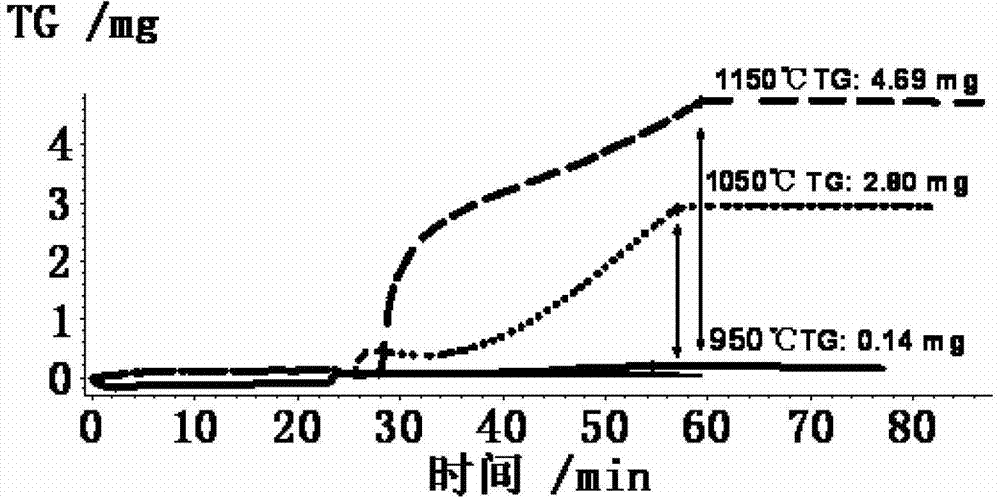

[0028] The invention is based on 55SiCr spring steel 2%O 2 It is applied in the oxidative decarburization simulation test of heating to 950, 1050, and 1150℃ for 30 minutes under the atmosphere. The specific steps are:

[0029] a. Use wire cutting to prepare samples of the same specifications with a diameter of 4.5mm and a height of 6mm;

[0030] b. After rough grinding and fine grinding, the surface of the sample is ultrasonically cleaned. The cleaning agent is 90% ethanol solution;

[0031] c. Place the prepared sample in a dynamic thermogravimetric analyzer with multiple gas paths and perform 4 vacuuming operations, and then set the test program as follows: under the protection of Ar gas, it is heated to 950 at 40℃ / min. 1050, 1150℃, and in 2%O 2 In the atmosphere, the temperature is kept for 30 minutes, and then it is rapidly reduced to room temperature at 40°C / min under the protection of Ar atmosphere. The total gas flow rate remains unchanged during the entire experiment.

[003...

Embodiment 3

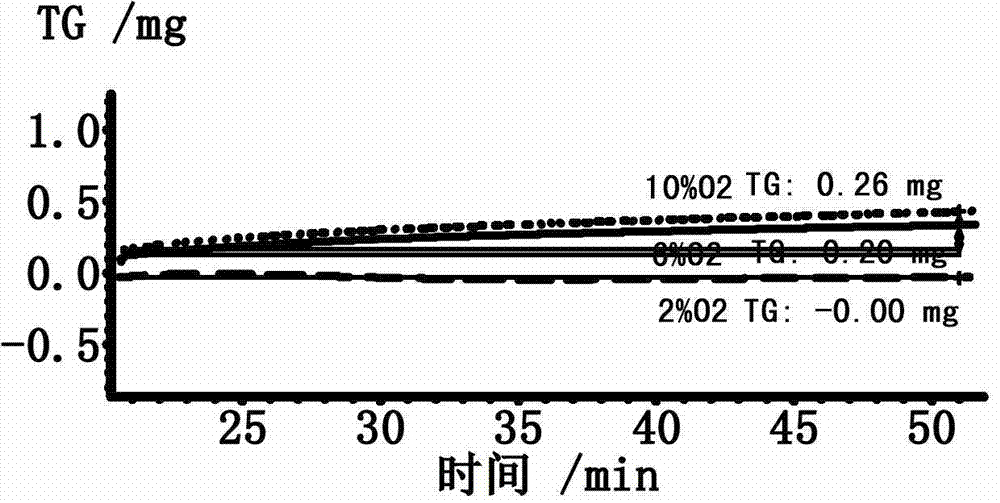

[0035] In the present invention, 55SiCr spring steel is heated to 850℃, and the temperature is 2%, 6%, and 10% O 2 It was applied in the oxidative decarburization simulation test which was kept at each temperature for 30 minutes. The specific steps are:

[0036] a. Use wire cutting to prepare samples of the same specifications with a diameter of 4.5mm and a height of 6mm;

[0037] b. After rough grinding and fine grinding, the surface of the sample is ultrasonically cleaned. The cleaning agent is 90% ethanol solution;

[0038] c. Place the prepared sample in a dynamic thermogravimetric analyzer with multiple gas paths and perform 5 vacuuming operations, and then set the test program as follows: under the protection of Ar gas, the temperature is increased rapidly at 40℃ / min and heated to 850℃ , Respectively in 2%, 6%, 10%O 2 In the atmosphere, the temperature is kept for 30 minutes, and then it is quickly reduced to room temperature at 40°C / min under the protection of Ar atmosphere....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com