Display method of austenitic grain boundary of medium-manganese steel for automobile

A technology of austenite grain boundary and display method, which is applied in the field of display of original austenite grain boundary of medium-manganese automobile steel, which can solve problems such as inconvenient use, cumbersome experimental operation, and expensive experimental detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

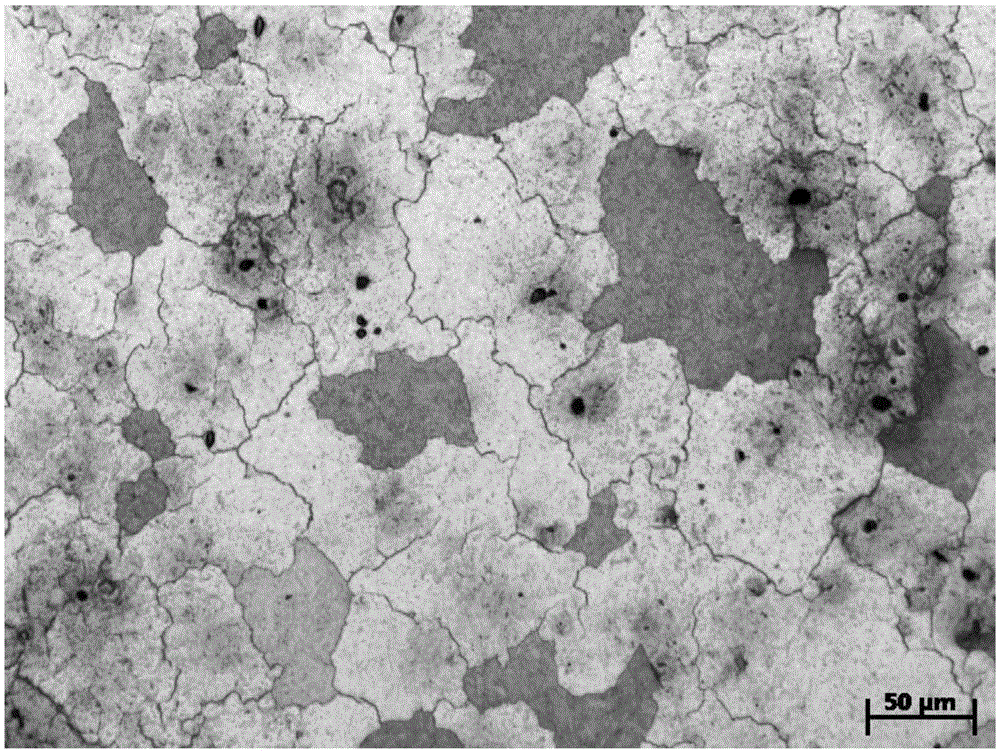

Embodiment 1

[0065] The method for displaying the grain boundaries of prior austenite in medium-manganese automobile steel comprises the following steps:

[0066] Step 1. Sample Preparation

[0067] (1) Sample processing: Take medium manganese automobile steel, the content of which is by mass percentage: C: 0.05%, Si: 0.01%, Mn: 3%, Al: 1.0%, V: 0.03%, Ti: 0.03%, Nb: 0.03%, P: 0.07%, S: 0.005%, and the balance is Fe; processed into a cylinder, and the surface is polished to obtain a cylindrical sample with a diameter of 6mm and a height of 10mm, and the surface finish of the cylindrical sample is above ▽7;

[0068] (2) Thermal deformation treatment: The cylindrical sample is thermally compressed and deformed on a thermal simulation test machine. The deformation temperature is 700°C, the strain rate is 0.01 / s, and the strain is 20%. After the deformation is completed, it is quenched in water immediately to form a cake-shaped sample ;

[0069] (3) Sample cutting and inlaying: divide the ca...

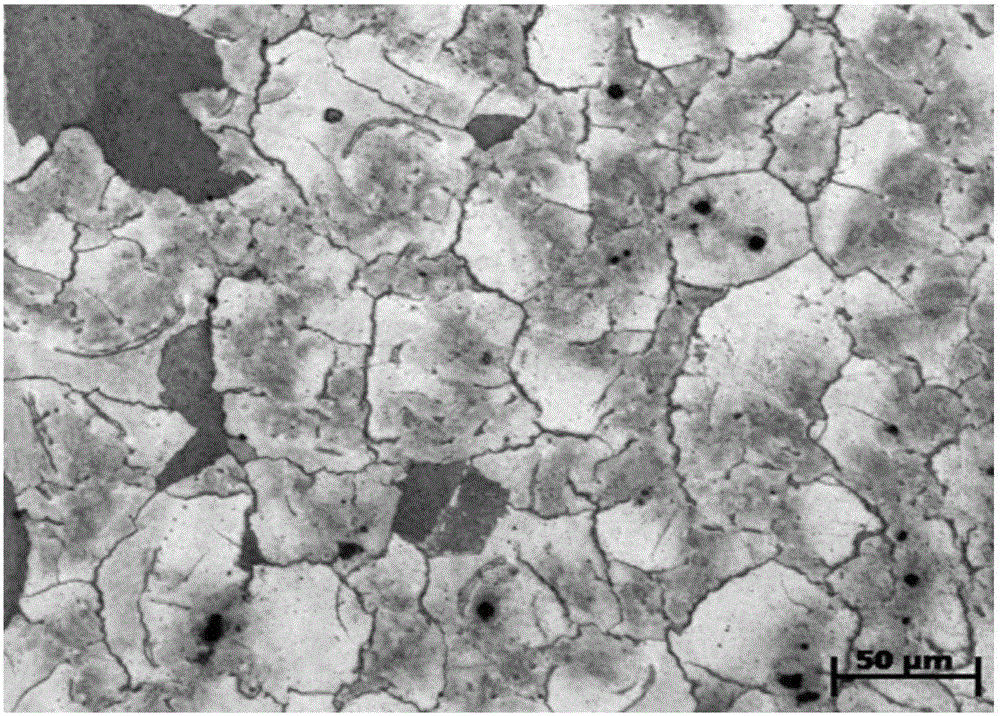

Embodiment 2

[0089] The method for displaying the grain boundaries of prior austenite in medium-manganese automobile steel comprises the following steps:

[0090] Step 1. Sample Preparation

[0091] (1) Sample processing: Take medium-manganese automobile steel, the content of which is by mass percentage: C: 0.1%, Si: 0.05%, Mn: 5%, Al: 1.5%, V: 0.05%, Ti: 0.05%, Nb: 0.05%, P: 0.05%, S: 0.01%, and the balance is Fe; process it into a cylinder, and perform surface polishing to obtain a cylindrical sample with a diameter of 6mm and a height of 12mm, and the surface finish of the cylindrical sample is above ▽7;

[0092] (2) Thermal deformation treatment: The cylindrical sample is thermally compressed and deformed on a thermal simulation test machine. The deformation temperature is 800°C, the strain rate is 0.05 / s, and the strain is 30%. After the deformation is completed, it is water-quenched immediately to form a cake-shaped sample ;

[0093] (3) Sample cutting and inlaying: divide the cake...

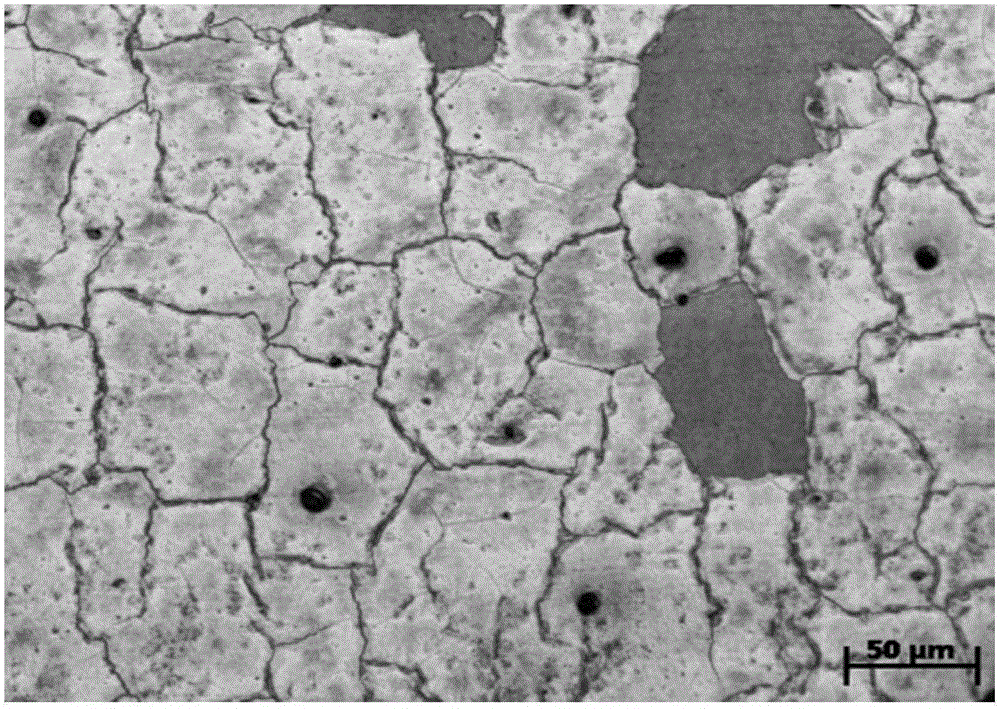

Embodiment 3

[0113] The method for displaying the grain boundaries of prior austenite in medium-manganese automobile steel comprises the following steps:

[0114] Step 1. Sample Preparation

[0115] (1) Sample processing: Take medium-manganese automobile steel, the content of which is by mass percentage: C: 0.3%, Si: 0.5%, Mn: 7%, Al: 1.8%, V: 0.08%, Ti: 0.07%, Nb: 0.08%, P: 0.05%, S: 0.03%, and the balance is Fe; processed into a cylinder, and the surface is polished to obtain a cylindrical sample with a diameter of 7mm and a height of 12mm, and the surface finish of the cylindrical sample is above ▽7;

[0116] (2) Thermal deformation treatment: Thermal compression deformation is performed on the cylindrical sample on a thermal simulation test machine. The deformation temperature is 900°C, the strain rate is 0.1 / s, and the strain amount is 40%. ;

[0117] (3) Sample cutting and inlaying: divide the cake-shaped sample into two along the direction of the central axis, cut the central long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com