Plasma display panel and method of manufacturing the same

A display panel and plasma technology, which is applied in the direction of alternating current plasma display panel, cold cathode manufacturing, electrode system manufacturing, etc. The effect of discharge space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described below with reference to the drawings.

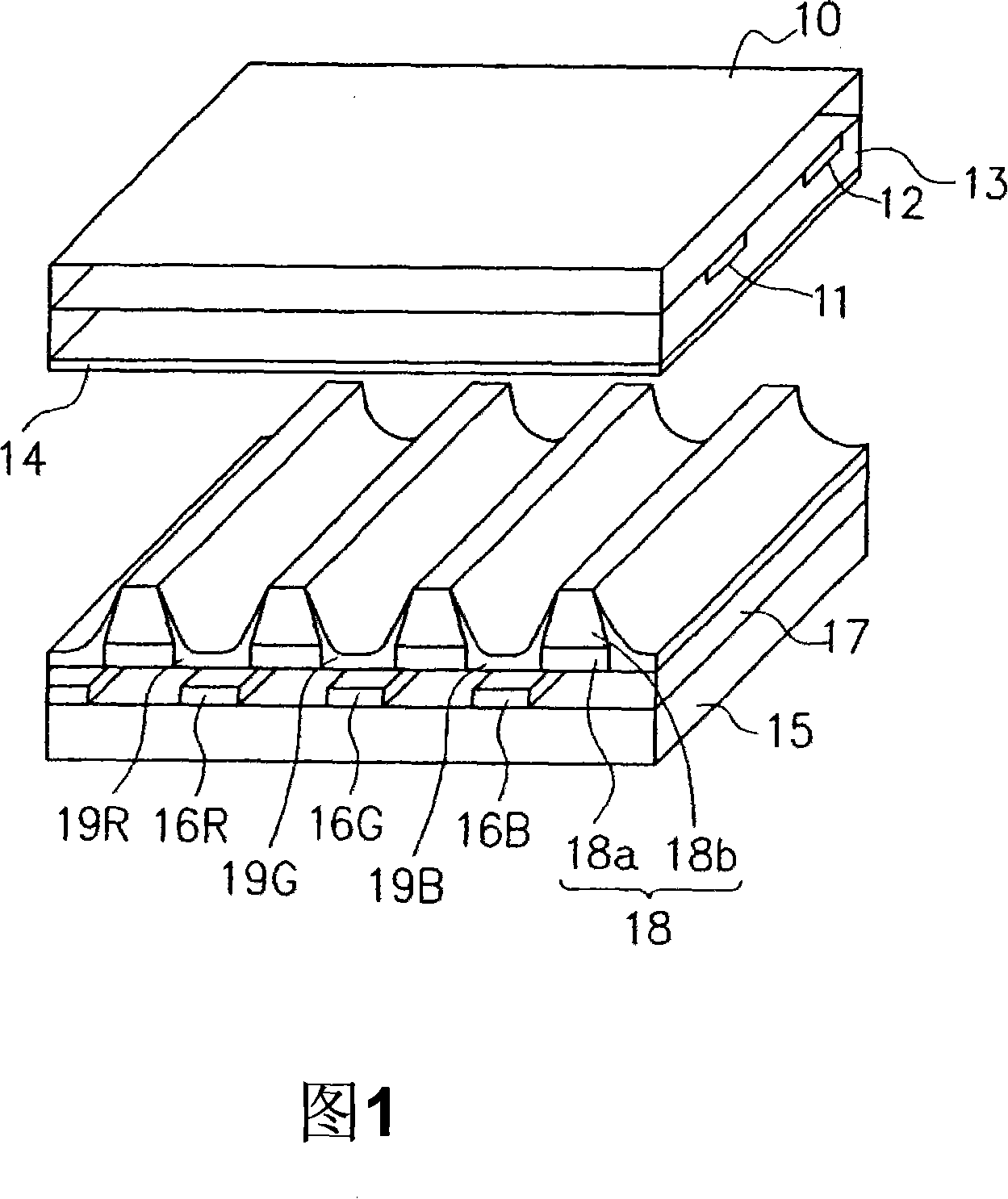

[0036] FIG. 1 is an exploded perspective view showing a configuration example of a plasma display panel according to one embodiment of the present invention.

[0037] On front glass substrate 10 , X electrodes (sustain electrodes) 11 and Y electrodes (scan electrodes) 12 for performing sustain discharge are arranged in parallel and alternately. A dielectric layer 13 made of low-melting glass or the like is covered thereon. Further, a protective layer 14 of MgO (magnesium oxide) is covered thereon. That is, the X electrodes 11 and the Y electrodes 12 arranged on the front glass substrate 10 are covered with the dielectric layer 13 , and their surfaces are covered with the protective layer 14 .

[0038] Address electrodes 16R, 16G, and 16B are formed on rear glass substrate 15 facing front glass substrate 10 in a direction perpendicular to (intersecting) X electrodes 11 and Y ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com