Fibrosis dip-squeeze device of fabric pad dyeing equipment

A fiber degeneration and padding technology, which is applied in the processing of textile materials, textiles and papermaking, textile processing machine accessories, etc. Uniform treatment to meet the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the drawings.

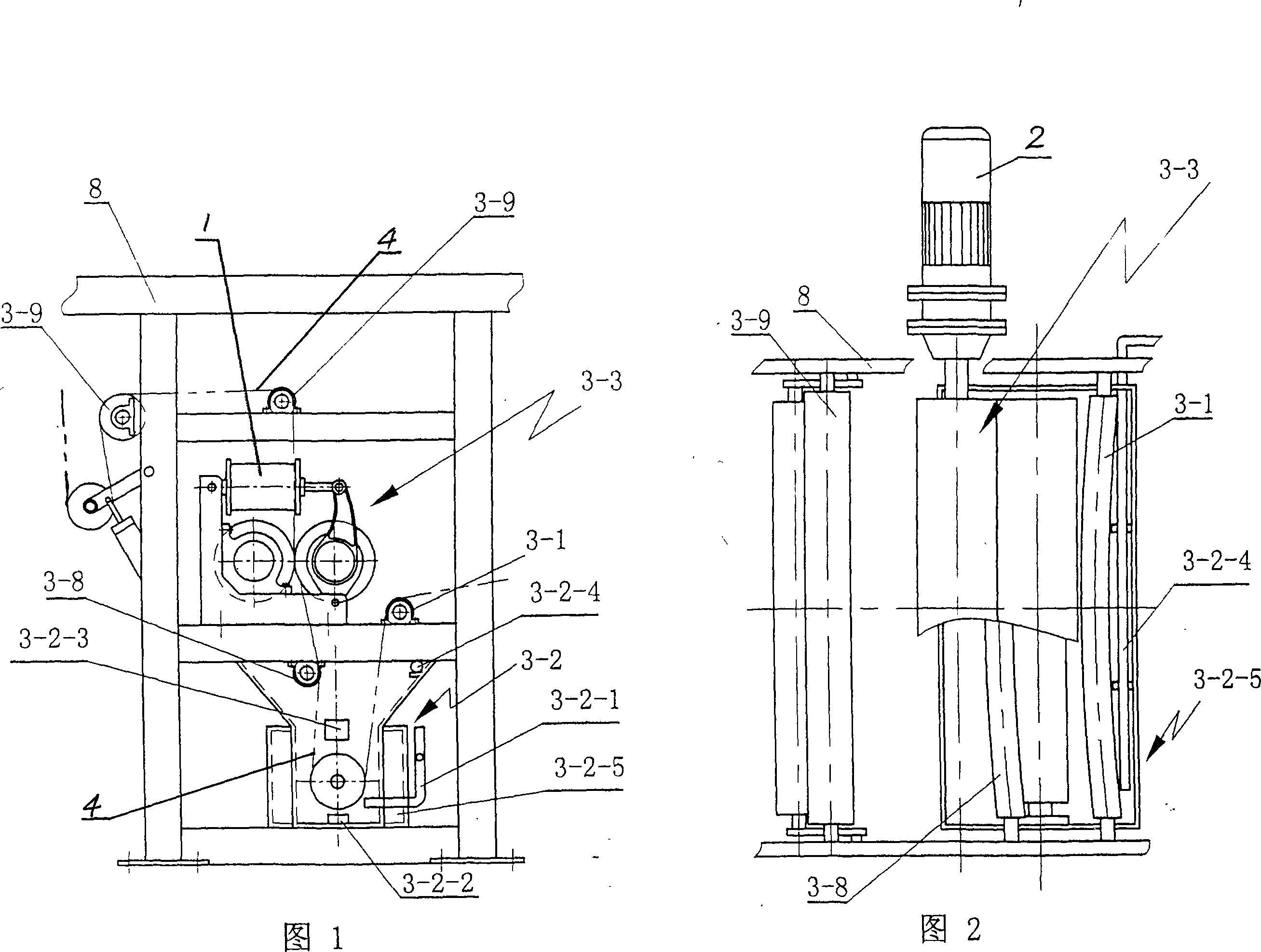

[0014] As shown in Figures 1 and 2, the grey cloth 4 moves through the following devices in sequence: the expansion bay roller 3-1 installed on the frame 8, the dipping tank 3-2 containing the denaturant, and the front expansion The web roller 3-8 is a rolling pair consisting of two rollers 3-3 contacting the outer walls above the opening of the dipping tank, and is turned to the cloth roller 3-9.

[0015] The dipping tank 3-2 is equipped with a liquid level control mechanism 3-2-1, and an ultrasonic oscillator 3-2-2 and a temperature controller 3-2-3 are installed under the liquid surface of the denaturant in the tank. A uniform replenishment mechanism 3-2-4 is arranged along the length of the slot with the liquid outlet evenly arranged along the length of the slot. The slot body of the dipping tank is a jacketed tank body communicating with the cold and hot fluid medium. The purpose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com