Deep sea optical cable coupling box and connecting process thereof

An optical cable splice box, deep-sea technology, applied in the direction of optical fiber/cable installation, fiber mechanical structure, etc., can solve the problem of not meeting the deep-sea optical cable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

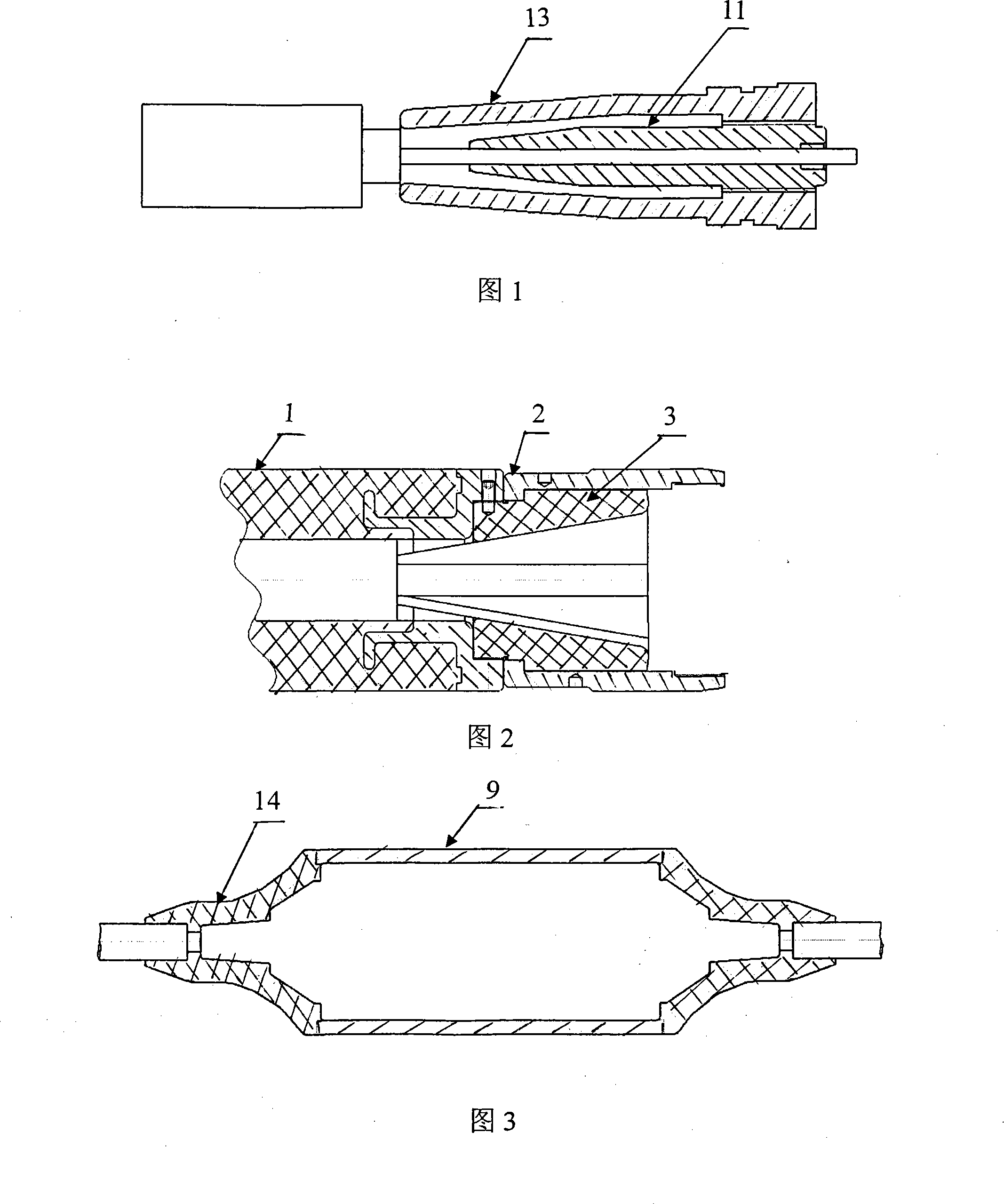

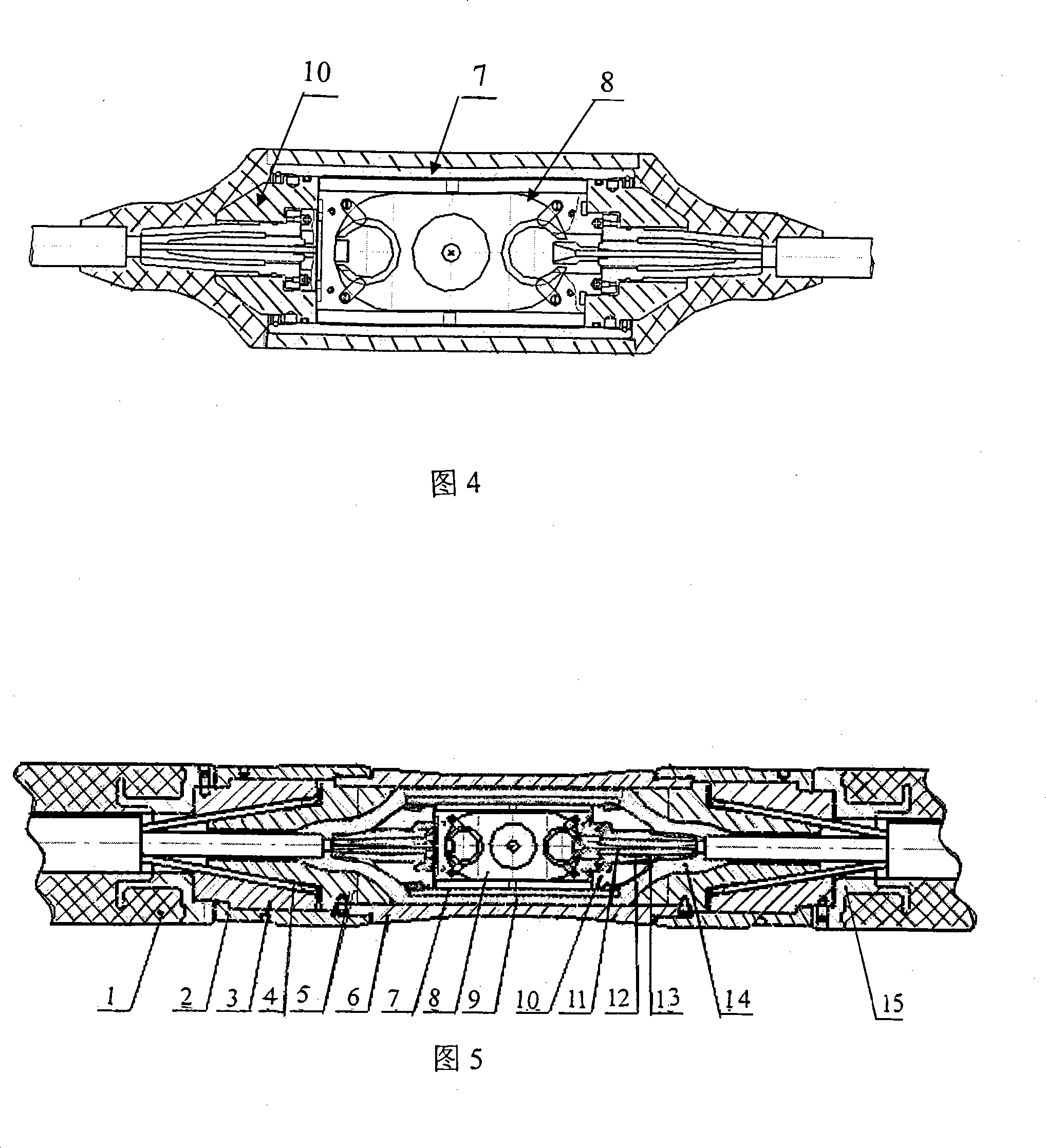

[0022] Referring to accompanying drawings 1, 2, 3, 4, the structure of the deep-sea optical cable joint box includes a bending limiter 1, an outer cylinder nut 2, an outer cone seat 3, an outer armor wire 4, an outer cone shaft 5, and an outer cylinder 6. Inner cylinder body 7, fiber storage disc 8, prefabricated cylinder 9, bearing nut 10, inner cone shaft 11, inner armor wire 12, inner cone pressure sleeve 13, and injection molded sealing body 14. The bend limiter 1 is provided with a universal joint 15 .

[0023] The fiber storage tray 8 is threaded in the middle of the load-bearing nut 10; the inner cone shaft 11 and the inner cone pressure sleeve 13 form an inner armor wire fixing device, which is connected with the load-bearing nut 10; the inner cylinder 7 is set on the two load-bearing nuts 10 ; The prefabricated cylinder 9 is set on the inner cylinder body, and is connected with the deep-sea optical cable core through the injection molding sealing body 14; The cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com