Plane parallel mechanism with constrained branched chain and its widening robot unit

A manipulator and plane technology, applied in the direction of manipulators, claw arms, manufacturing tools, etc., can solve the problems of low precision, limited carrying capacity, difficult running speed and acceleration, etc., and achieve the effect of improving work efficiency, simple structure, and easy high-speed movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

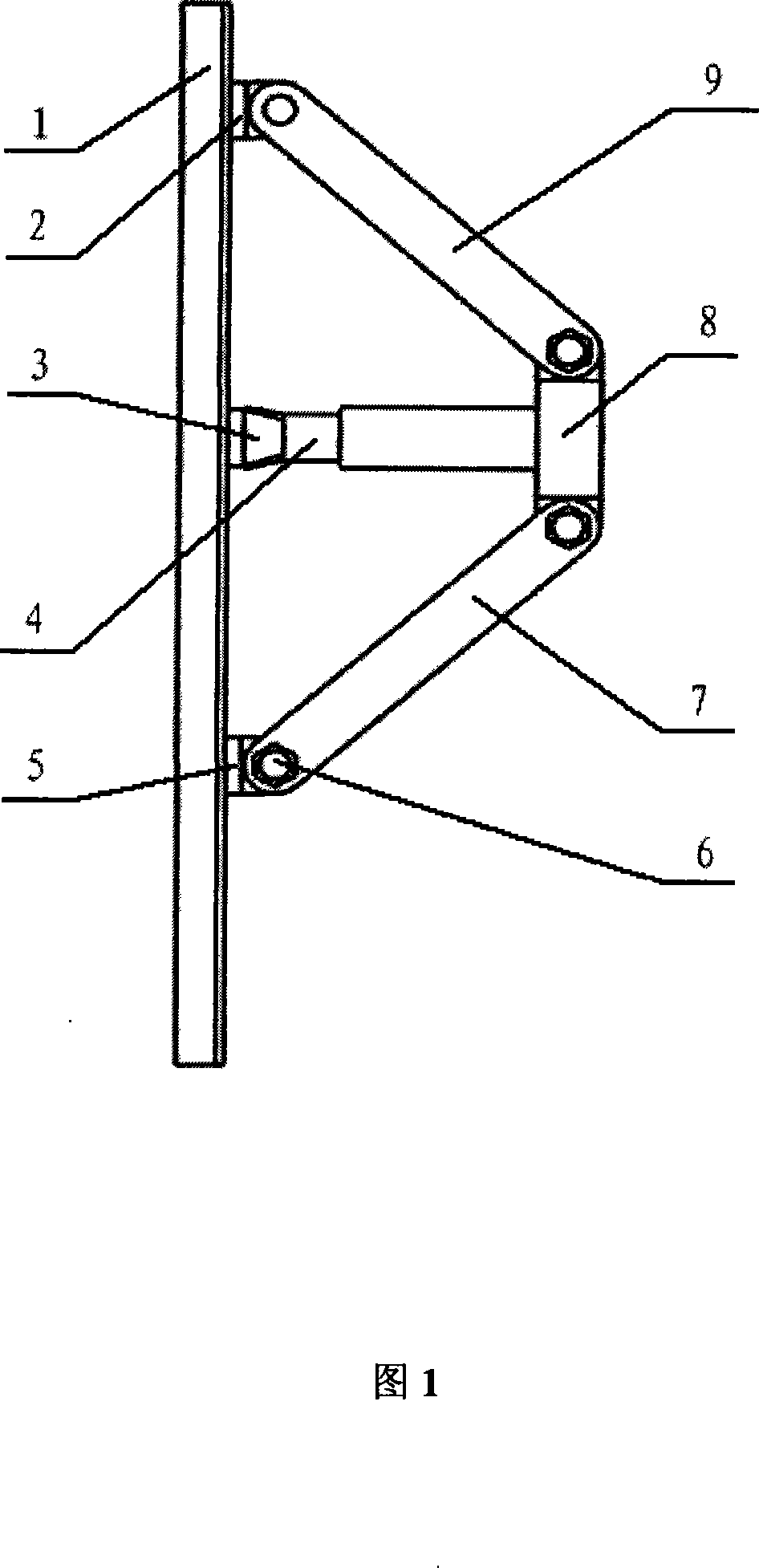

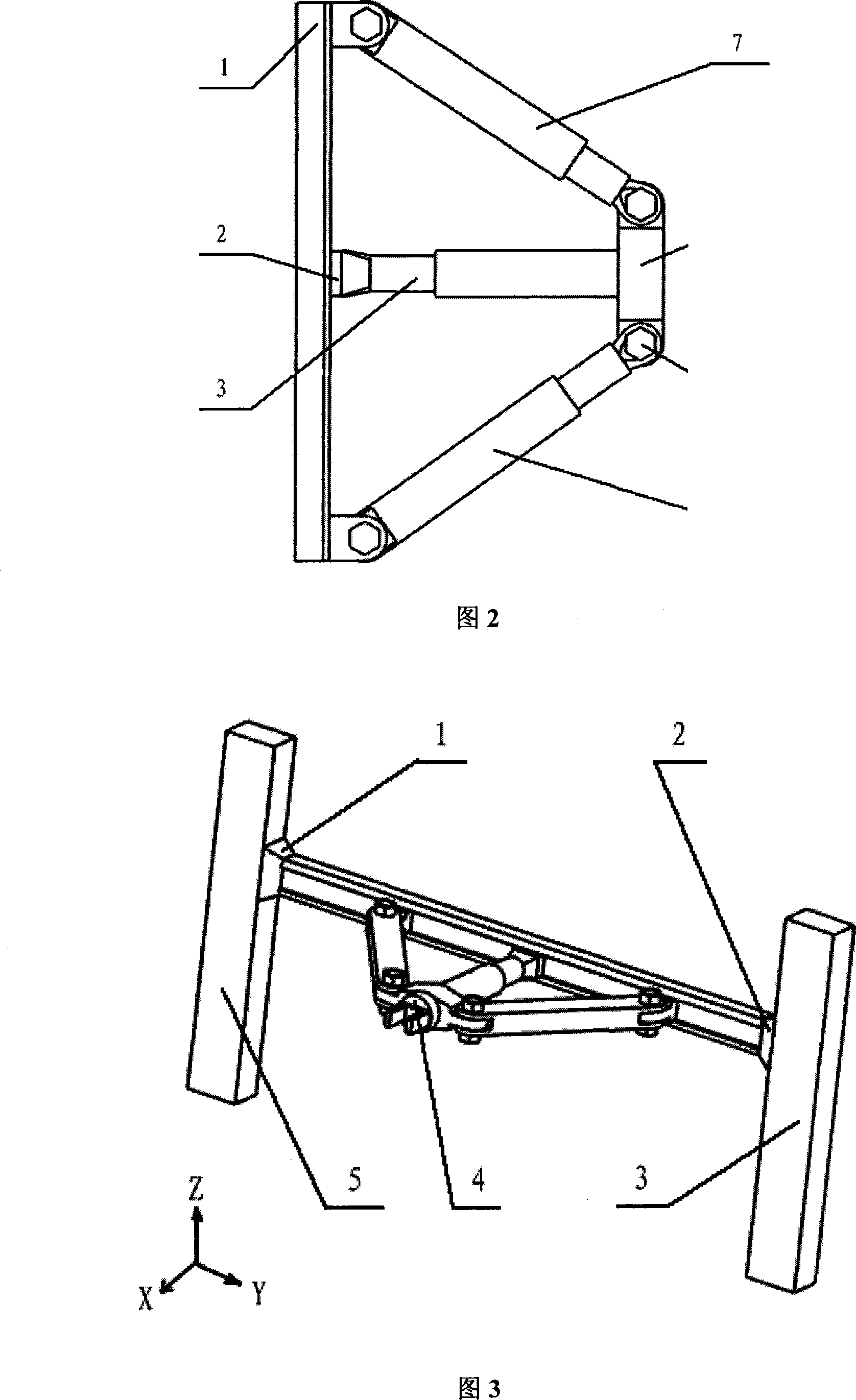

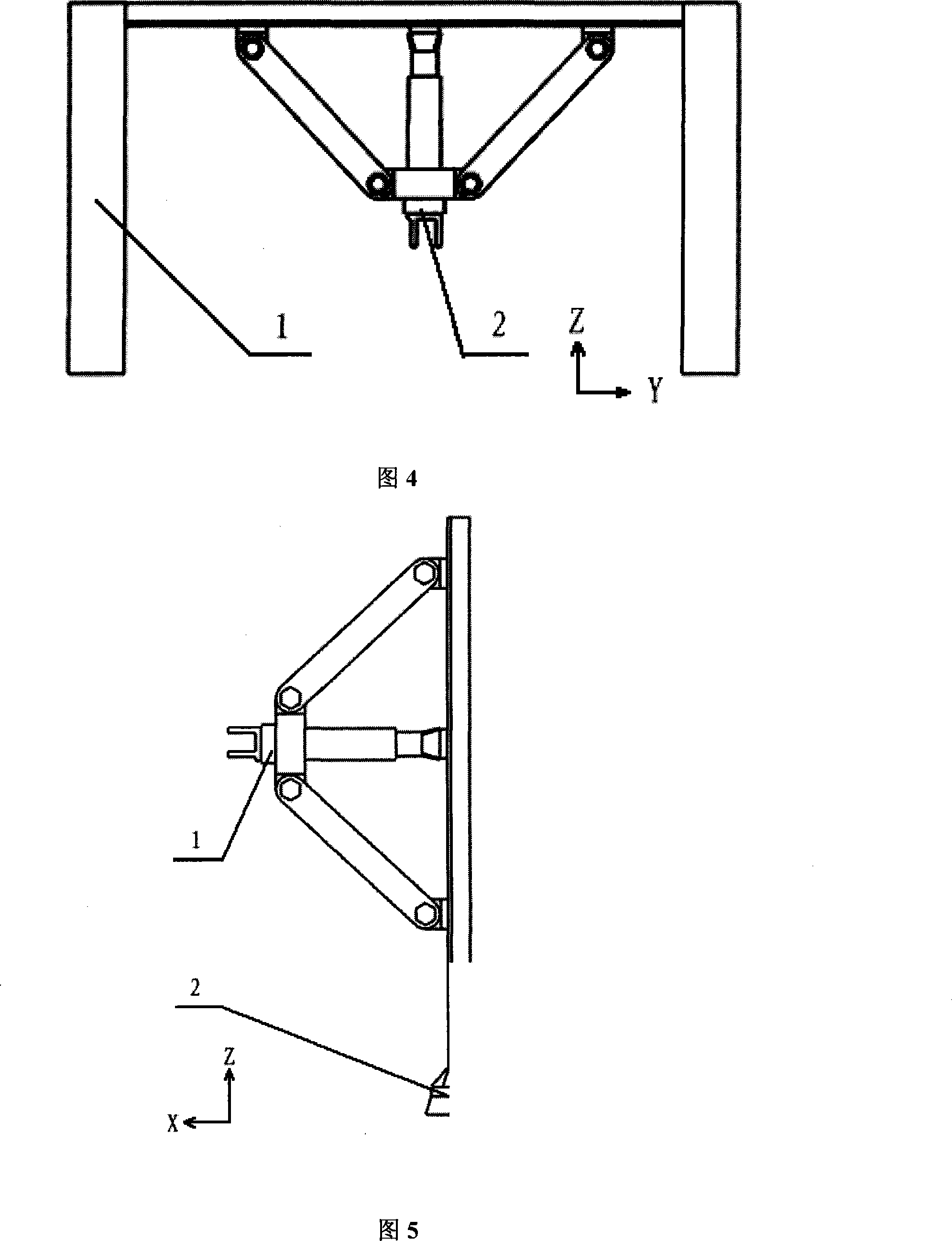

[0026] The working principle of the planar parallel mechanism, which is the core part of this design, will be introduced in detail below in conjunction with the accompanying drawings.

[0027] As shown in Figure 1, the slider drive parallel mechanism consists of fixed length rods 8, 10, output platform 9, active slider 2, active slider 5, and sliding guide rail 1 to form a planar parallel closed-chain structure. Due to the frame structure, the entire structure is very light in weight.

[0028] Fixed-length rods 8,10, slide blocks 2,5 and output platform 9 hinged therewith, plus a plane parallel mechanism formed by guide rail 1, have good rigidity. One end of the telescopic rod 4 is fixed to the follower slider 3 , and the other end is fixed to the output platform 9 to limit the swinging freedom of the output platform 9 . When the sliders 2 and 5 change positions, the hinge points of the rods 8 and 10 also change accordingly, and the positions and postures of the rods 8 and 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com