Converter with continuously adjustable output

A converter and output technology, applied in the field of improvement of voltage converter circuits, can solve the problems of increasing the steps of the driving circuit, cost and complexity, limitation of the maximum duty cycle of the circuit, electromagnetic interference, etc. Immediate simplicity of stability, reduction in size and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

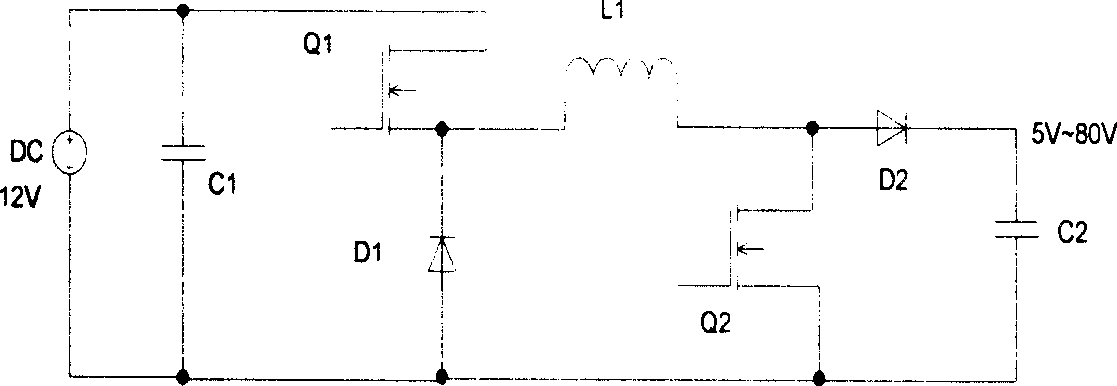

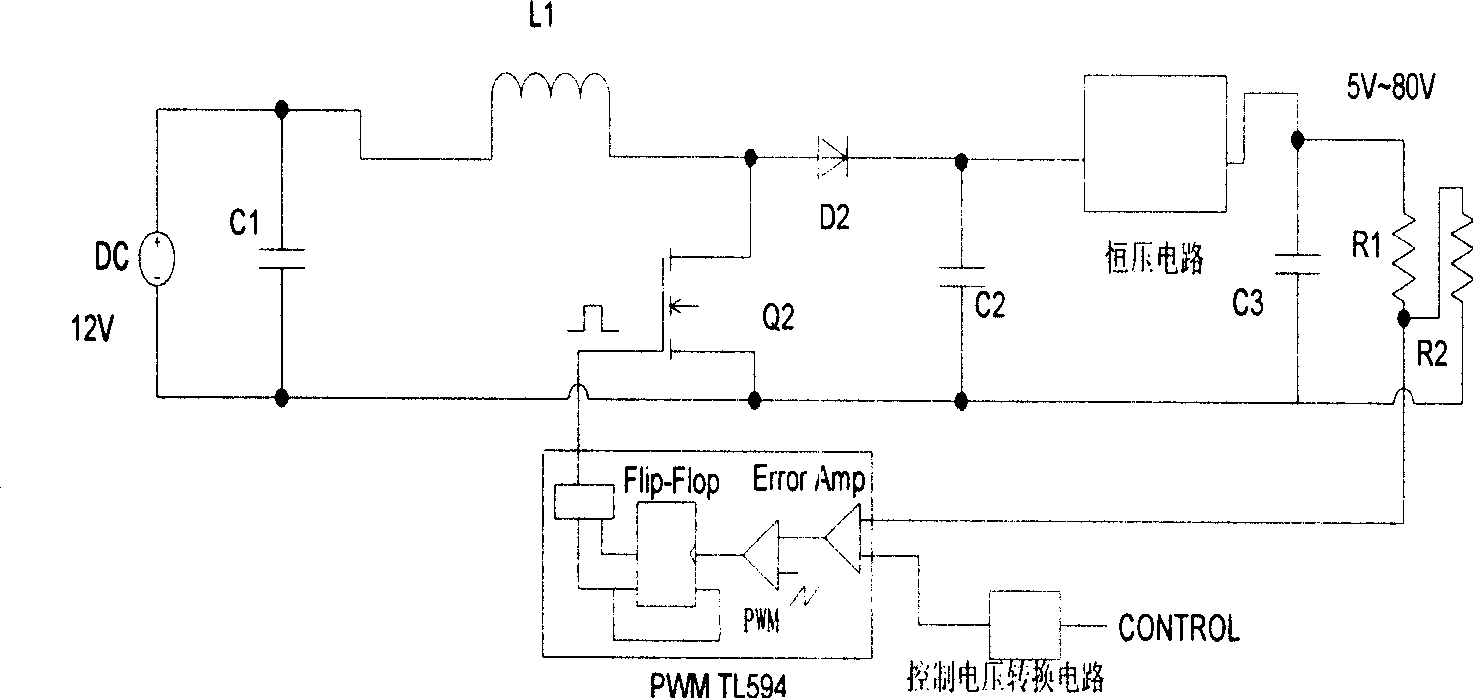

[0022] The voltage converter of the present invention is as figure 2 As shown, it is mainly composed of four parts of the circuit, namely the BOOST converter circuit (Boost Converter), the constant voltage circuit (Fixed Voltage Regulator Circuit), the control voltage conversion circuit (Voltage Shift Circuit) and the PWM controller (PWM Controller). The BOOST conversion circuit realizes the function of boosting the voltage. The constant voltage circuit is used to generate a fixed voltage difference to compensate the inherent deviation between the lowest output voltage and the input voltage of the BOOST circuit. The control voltage conversion circuit ensures that the control voltage and the output voltage are in a linear relationship. PWM controllers are used to implement feedback and control functions. The basic idea of the present invention is that u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com