Fastener

A technology for fasteners and components, applied in the field of fasteners, can solve problems such as inability to pull out, complex manufacturing, etc., and achieve the effect of large tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

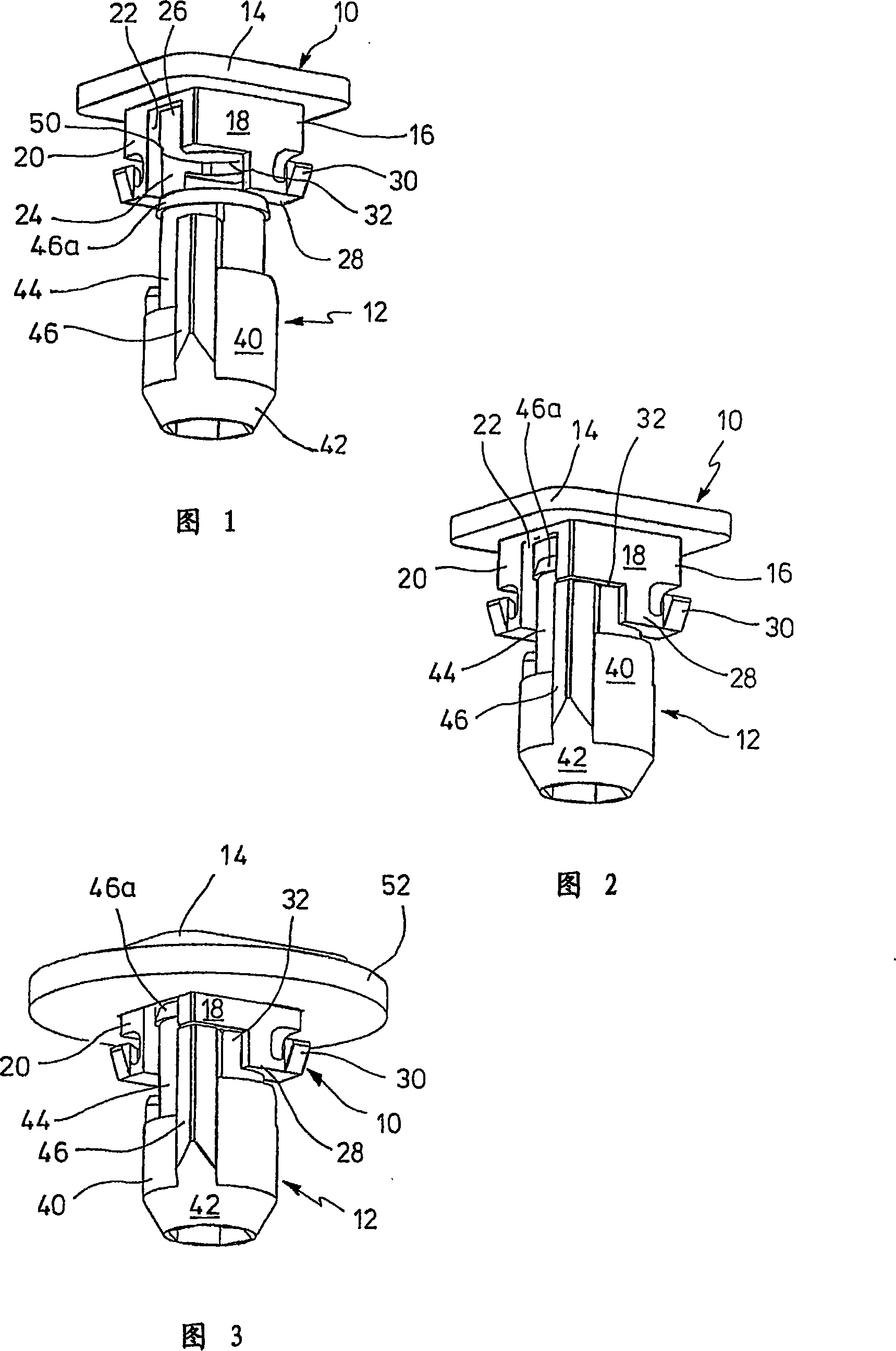

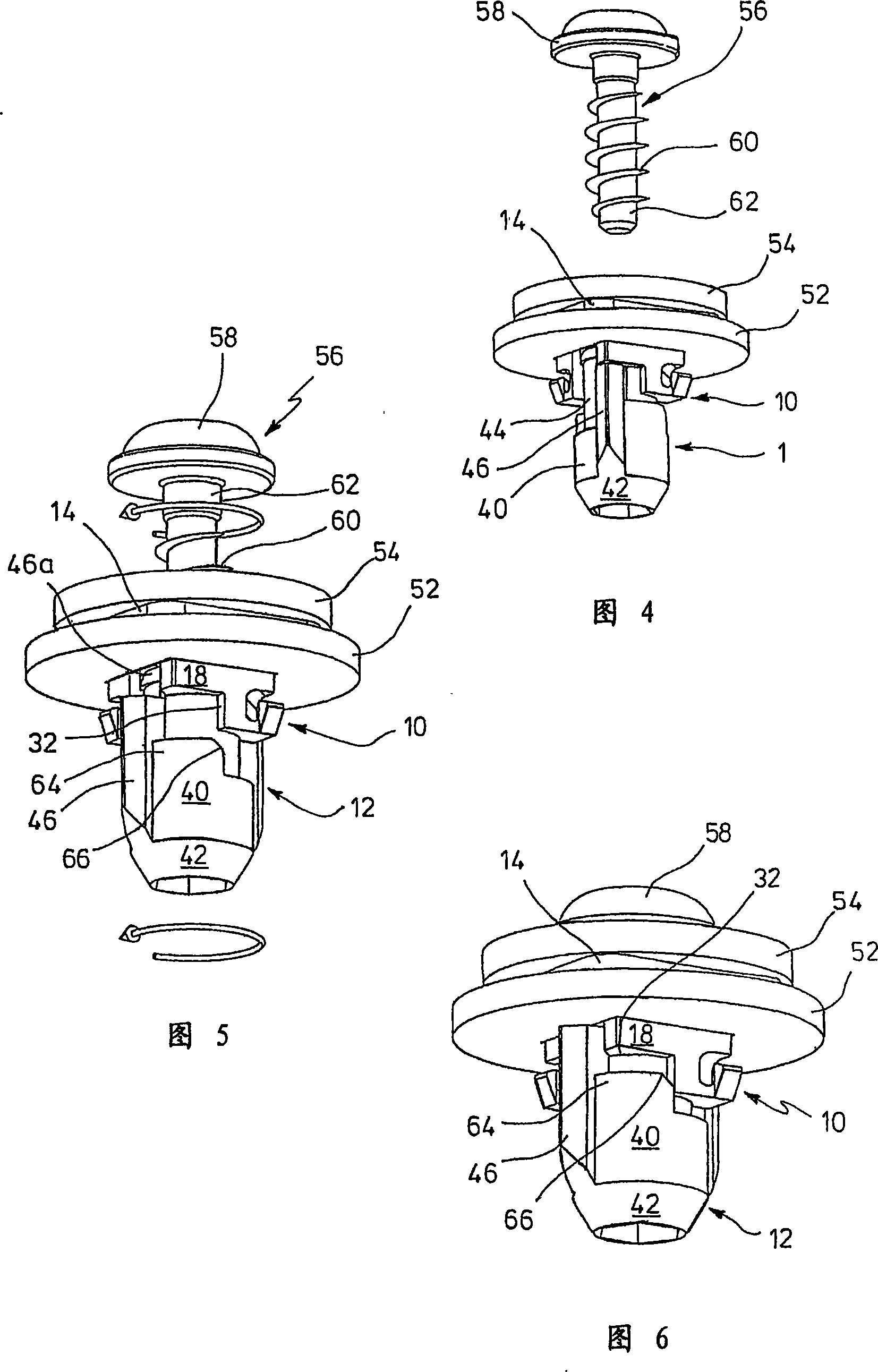

[0019] As shown in FIGS. 1 to 6 , the present invention includes a retainer 10 and a nut 12 . The holder 10 has a rectangular flange 14 and a shank 16 that is square in cross-section. The handle has two mutually opposite and continuous rectangular sides 18 and two other mutually opposite sides 20 separated by a gap 22, only one side 18 or 20 being shown in FIGS. 1 to 6 . It will be appreciated that certain opposing sides are the same.

[0020] In FIG. 1 , the shank 16 is substantially hollow and is defined by an inner cylindrical surface. The diameter of the first cylindrical surface 24 is slightly smaller than the diameter of the upwardly adjoining cylindrical surface 26 adjacent the flange 14 . As shown, cylindrical surfaces 24 are separated by gaps 26 .

[0021] At its end opposite the flange 14 , the handle 16 has a downwardly projecting projection 28 comprising a resilient hook 30 . The gap 32 is formed on the wall 18 in this way.

[0022] The nut 12 includes a lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com