Microwave oven with a drain orifice

A technology for microwave ovens and discharge ports, which is applied in the field of microwave ovens to achieve good contact and prevent arc generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

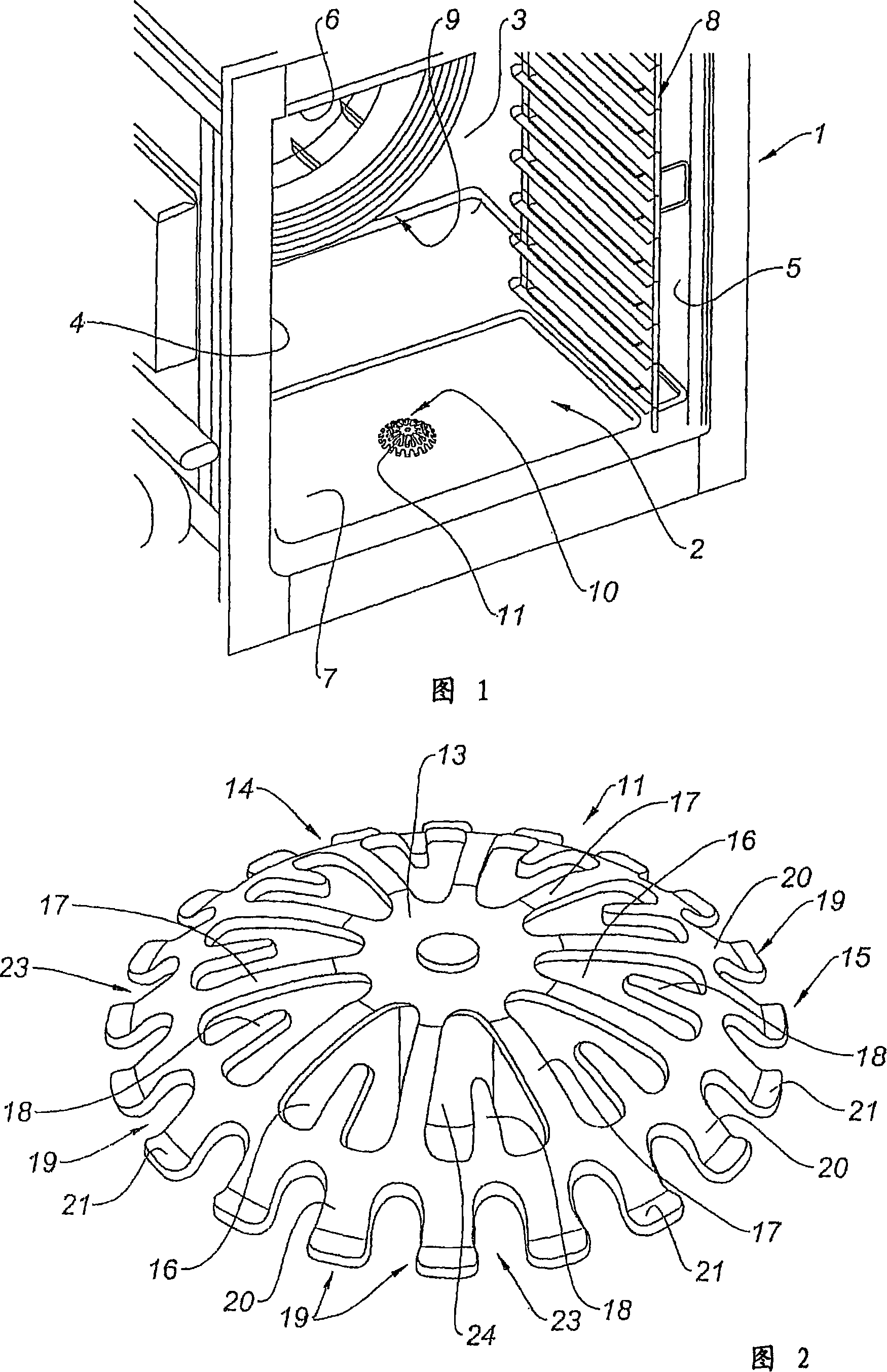

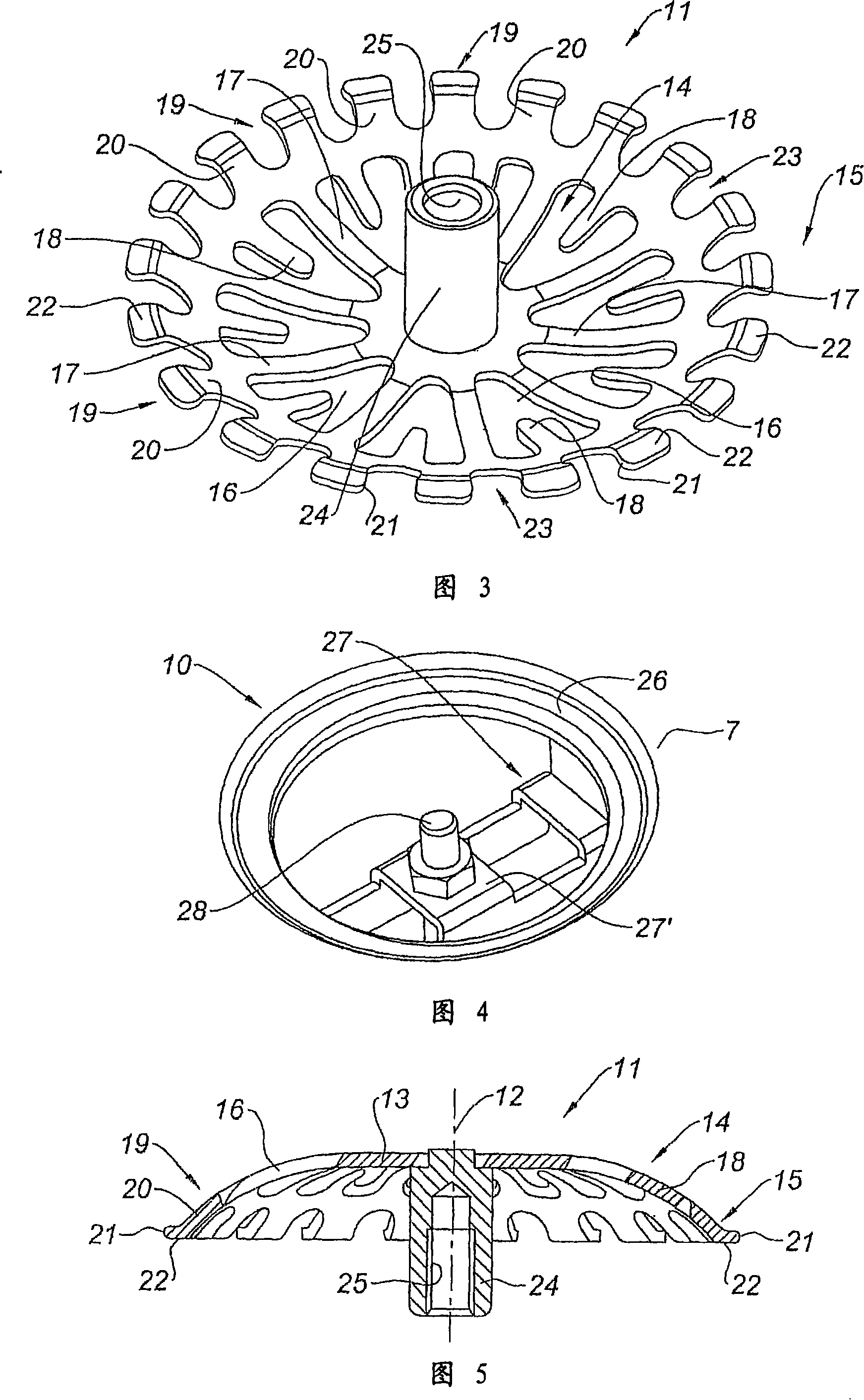

[0020] Referring to Fig. 1, the microwave oven 1 described here is a large public catering oven. It comprises a cooking or heating chamber 2 for food, this chamber 2 being formed by a rear wall 3 and two side walls 4, 5 (in particular the left side wall 4 and the right side wall 5 seen from the front), and a top plate 6 And bottom plate 7, and open towards the front. A door (not shown) is used to close the cavity 2 at the front during operation of the microwave oven 1 . The cavity 2 described here constitutes a volume of at least 0.15m 3 . The furnace comprises plate supports mounted on the side walls 4, 5, of which the right support 8 is as shown in Fig. 1 . The plate guides and supports, by means of these supports in the cavity 2, the food placed therein to be cooked, in a known manner.

[0021] The oven 1 described here is a combination oven, which in this case comprises steam heating means (not shown), convection heating means 9, and microwave generating means (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com