Method for preparing silicon nitride nanometer rod by using sulfur auxiliary reaction under low temperature

A technology of silicon nitride and nanorods, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of high reaction temperature and inability to obtain crystalline Si, achieve low reaction temperature, strengthen toughness, and realize industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of α-Si by reaction of silicon powder, sublimed sulfur and sodium azide 3 N 4 nanorod

[0028] Take 1 mmol of silicon powder, 2 mmol of sublimed sulfur and 4 mmol of sodium azide, put them into a stainless steel 20mL reaction kettle, remove the air in the kettle with nitrogen, seal it and place it in a resistance crucible boiler, and heat it at 250°C ( The furnace temperature is controlled at ±5°C) and 23.2MPa for 4-15 hours; 300°C and 25.4MPa for 1-5 hours; 400°C and 30MPa for 0.5-5 hours; after heating is stopped, the reaction The kettle was naturally cooled to room temperature; the kettle was opened, and the resulting product was washed 5 times with 10% hydrochloric acid, then washed with water until the pH was neutral, conventionally centrifuged, and dried to obtain α-Si 3 N 4 Nanorod-based silicon nitride powder products. Vacuum-dried at 60°C for 6 hours to obtain an off-white powder product.

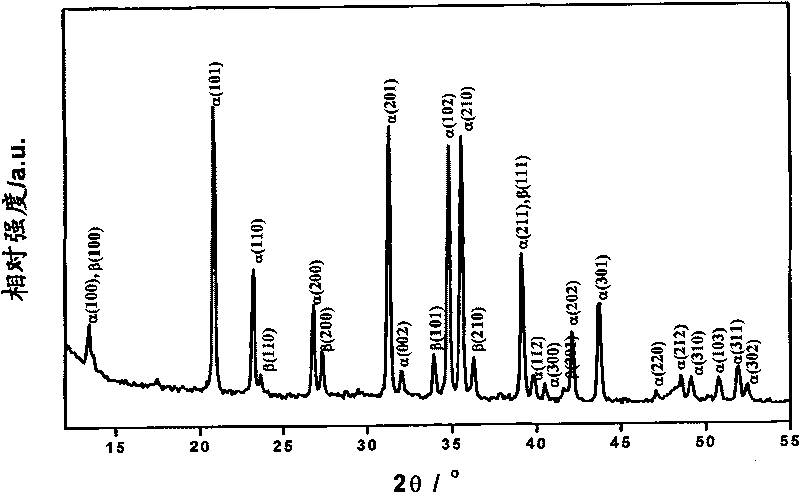

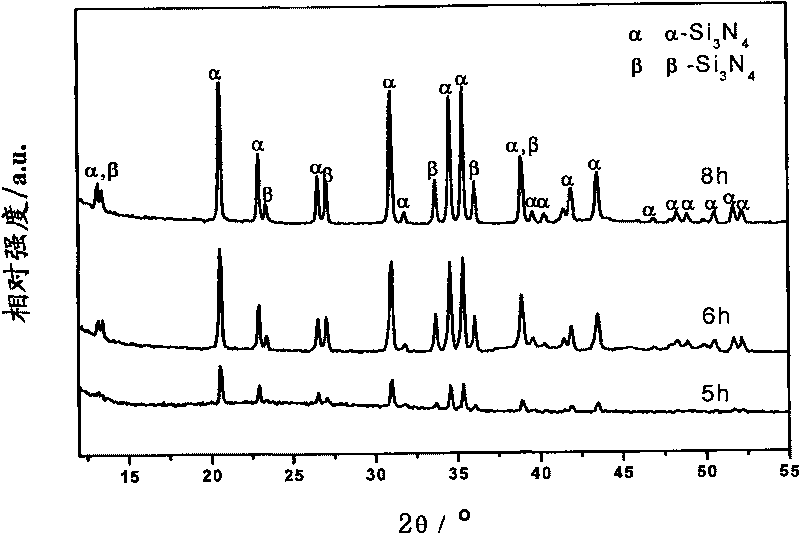

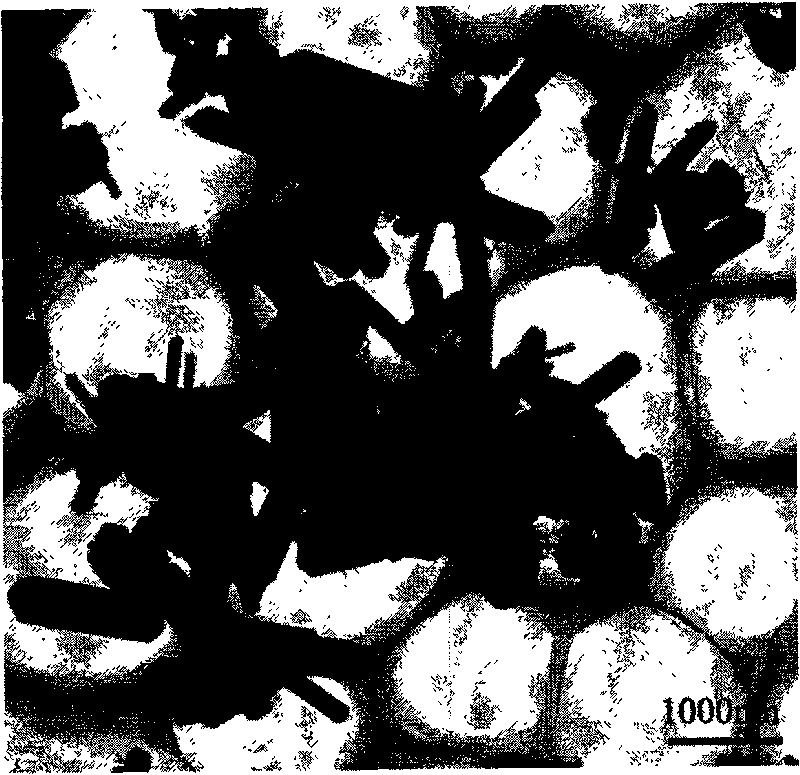

[0029] Cu Kα rays (wavelength λ=1.5418 The ...

Embodiment 2

[0038] Mix silicon powder, sublimed sulfur and sodium azide in a molar ratio of 1:3:6, seal in an autoclave, and react at 250°C and 36MPa for 12 hours; the product is washed 3 times with 5% sulfuric acid, and then washed with water until Neutral pH, routine centrifugation and drying to obtain α-Si 3 N 4 Nanorod-based silicon nitride one-dimensional nanomaterials.

Embodiment 3

[0040] Mix silicon powder, sublimed sulfur and sodium azide in a molar ratio of 1:2.5:5, seal it in an autoclave, and react for 4 hours at 300°C and 32.6MPa; the product is washed 3 times with 5% nitric acid, and then washed with water to neutral pH, conventional centrifugation and drying to obtain α-Si 3 N 4 Nanorod-based silicon nitride one-dimensional nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com