Screw rod extruding strings device

A screw and twin-screw technology, applied in the field of screw extruders, can solve problems such as increasing difficulty and aging time, uneven distribution, and affecting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

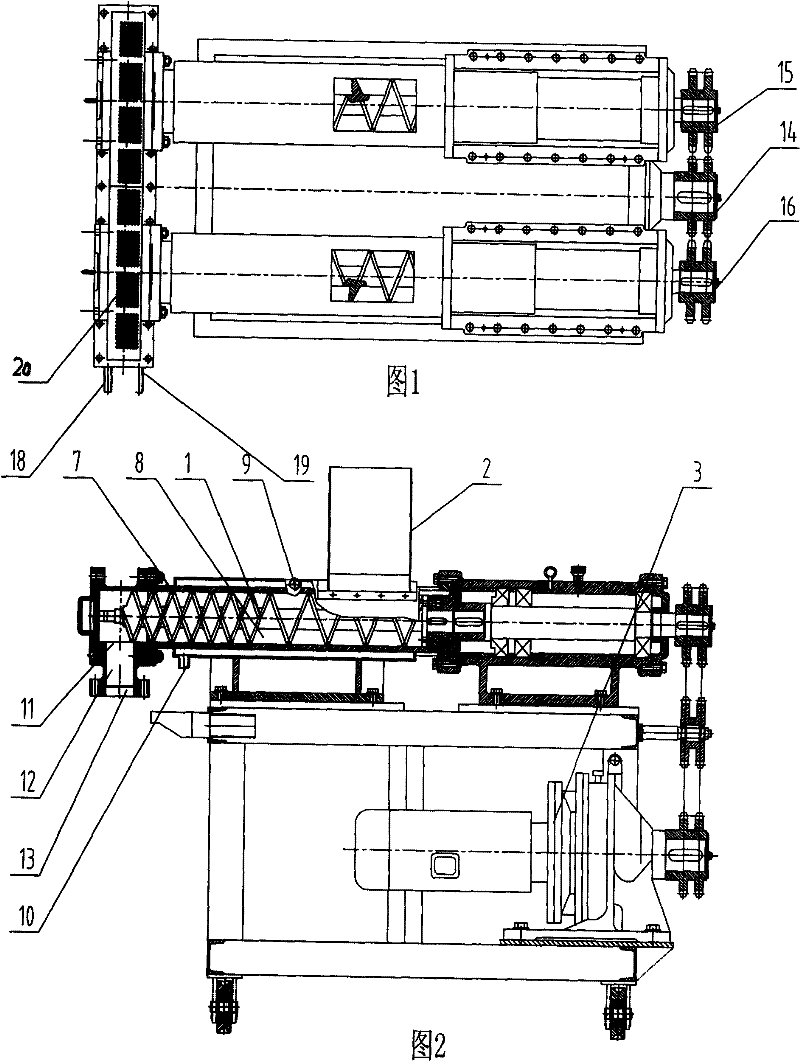

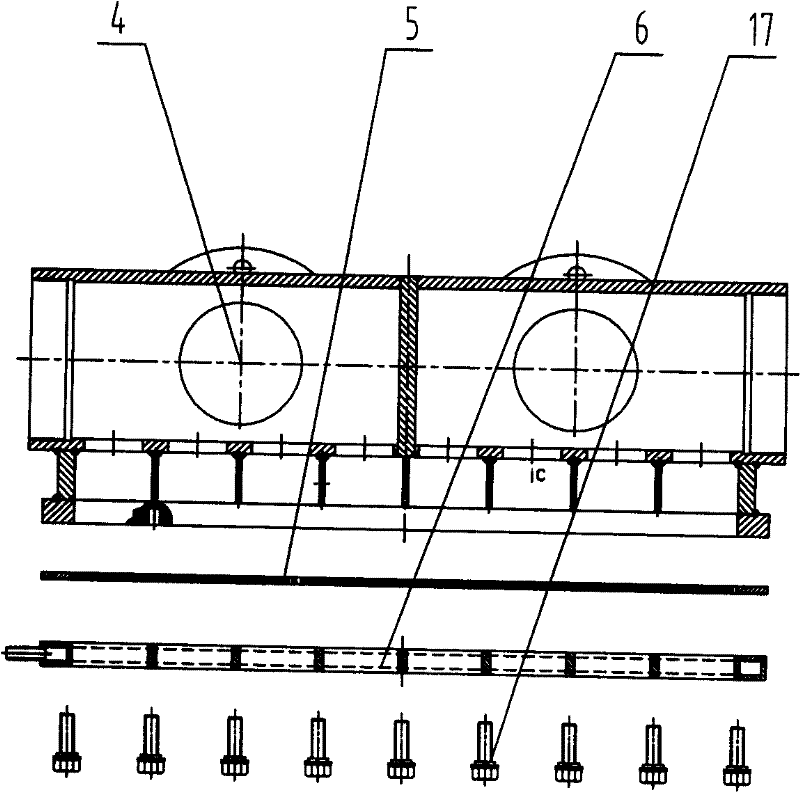

[0036] Such as Figure 5 to Figure 8 As shown, a twin-screw dough self-cooking extruder includes a screw drive mechanism and two screw mechanisms.

[0037]Each screw rod 25 is provided with a wire extruding cylinder 24, the screw rod 25 is accommodated in the cavity 30 of the extruding cylinder 24, the two ends of the extruding cylinder 24 are sealed, and the shaft of the screw rod 25 is installed on the seal at both ends of the extruding cylinder 24. on file. Each extruding cylinder 24 is provided with a feed port 23 , the feed port 23 opens upward and is close to the end of the screw rod 25 . A discharge port 29 is provided on each extrusion cylinder 24 .

[0038] An independent heat insulation box 31 is also provided outside each extrusion cylinder 24, the extrusion cylinder 24 passes through the heat insulation box 31, and a closed space is formed between the heat insulation box 31 and the extrusion cylinder 24;

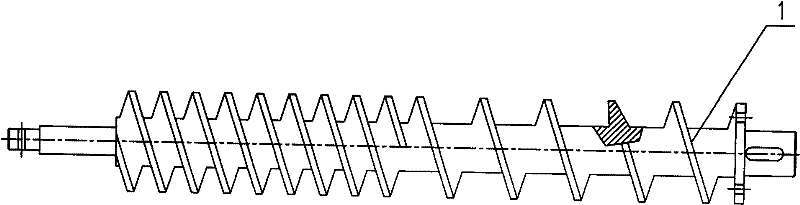

[0039] The screw rod 25 is a variable pitch screw rod 25...

Embodiment 3

[0044] Such as Figure 9 to Figure 11 As shown, a multi-screw powder slurry self-cooking extruder includes a screw drive mechanism and two screw mechanisms.

[0045] Each screw 51 is provided with a wire extruding cylinder 52, the screw 51 is accommodated in the cavity 60 of the extruding cylinder 52, the two ends of the extruding cylinder 52 are sealed, and the shaft of the screw rod 51 is installed on the seal at both ends of the extruding cylinder 52. on file. Each extruding tube 52 is provided with a feed port 55 , the feed port 55 opens upward and is close to the end of the screw rod 51 . A discharge opening 59 is provided on each extrusion tube 52 .

[0046] An independent heating cylinder 53 is also arranged outside each extrusion cylinder 52, and the extrusion cylinder 52 passes through the heating cylinder 53, forming a closed space between the heating cylinder 53 and the extrusion cylinder 52; The connected steam inlet 62 and steam outlet 63 are in communication w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Spiral length | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com