Integral drawer sliding rail component

An integrated, drawer technology, applied in drawers, furniture parts, household refrigeration devices, etc., can solve the problems of surface structure damage, looseness and disjointness of the inner side wall, increase the resistance noise of the push-pull drawer, etc., and achieves convenient manufacturing, processing and maintenance. The effect of deformation or tilt, quick installation or removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

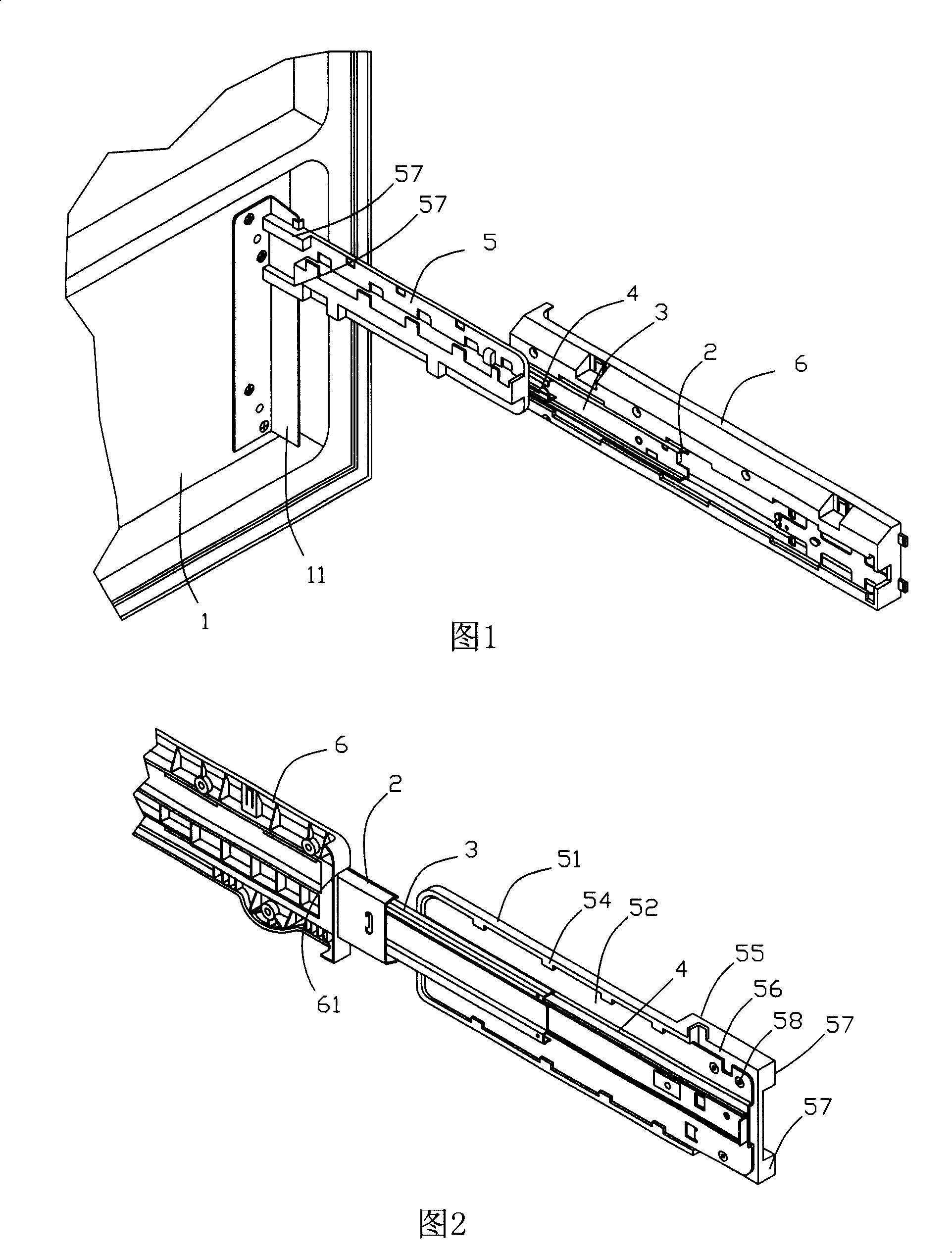

[0036] Embodiment 1, as shown in FIG. 1 and FIG. 2 , the integrated drawer slide rail assembly has a fixed rail 2 , a middle rail 3 , a sliding rail 4 , a sliding support frame 5 and a fixed support frame 6 . in,

[0037] In the three-section track including the fixed rail 2 , the middle rail 3 and the sliding rail 4 , the middle rail 3 is embedded in the fixed rail 2 , and the sliding rail 4 is embedded in the middle rail 3 . The other side of the sliding rail 4 is fixed in the sliding support frame 5 , while the other side of the fixed rail 2 is fixed in the fixed support frame 6 .

[0038] In the slide rail assembly in this embodiment, the three-section rail is connected and fixed to the sliding support frame 5 and the fixed support frame 6 to form an integral structure.

[0039] The sliding support frame 5 also includes a plastic connecting plate 51 and a metal fixing plate 52, the side of the metal fixing plate 52 punches out a Groove 53, slide rail 4 is fixed on by ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com