Semitrailer support

A semi-trailer and nut technology, which is used in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., can solve the problem of increased thread bending moment and shear force, reduced lifting capacity of outriggers, screw rod and nut stuck, etc. problems, achieve the effect of reducing wall thickness, reducing production cost and increasing lifting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

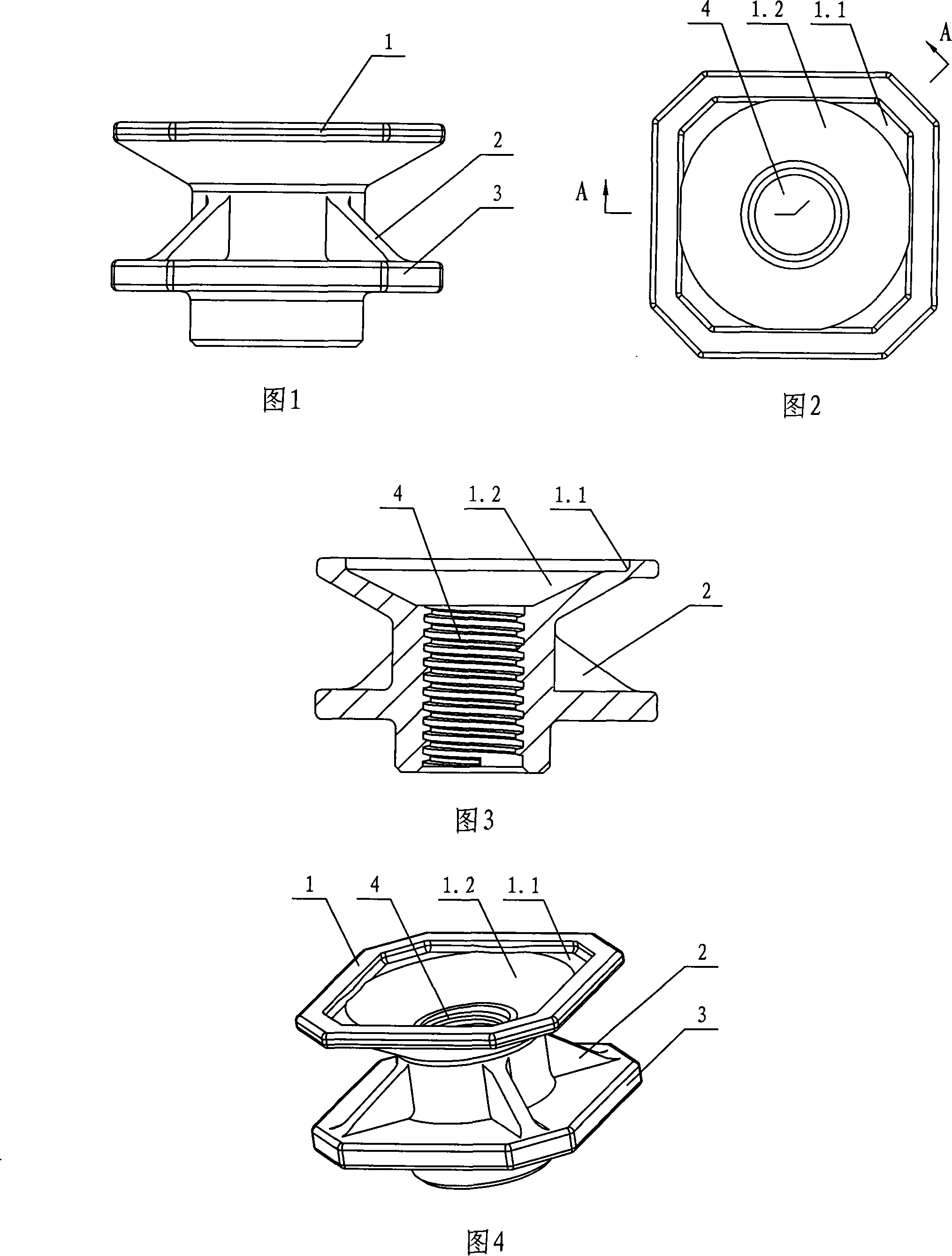

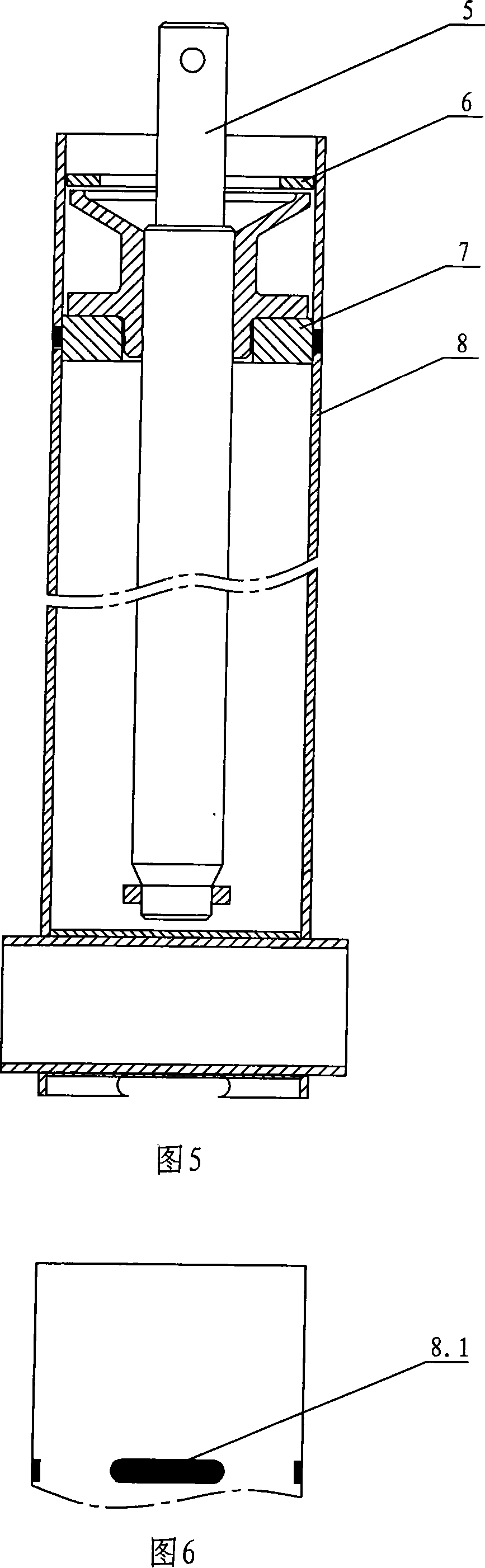

[0029] Referring to Fig. 1-Fig. 6, the first nut in the outrigger of the semi-trailer is a square structure of upper and lower layers, and a first reinforcing rib 2 is arranged between the upper layer 1 and the lower layer 3. The threaded hole 4 is set in the center, the upper layer 1 of the first nut is provided with a transition slope 1.1, the first oil storage groove 1.2 is located in the center of the transition slope, the first oil storage groove is funnel-shaped, the first oil storage groove and the screw thread Holes 4 communicate with each other; the first reinforcing ribs are four, in the shape of a right triangle, evenly distributed in the circumferential direction, facing the four cut corners, one of the right-angled sides is connected with the lower layer of the first nut, and the other right-angled side is connected with the middle cylinder of the first nut Body connected. The first nut is arranged in the square pipe 8, and its four corners are respectively provid...

no. 2 example

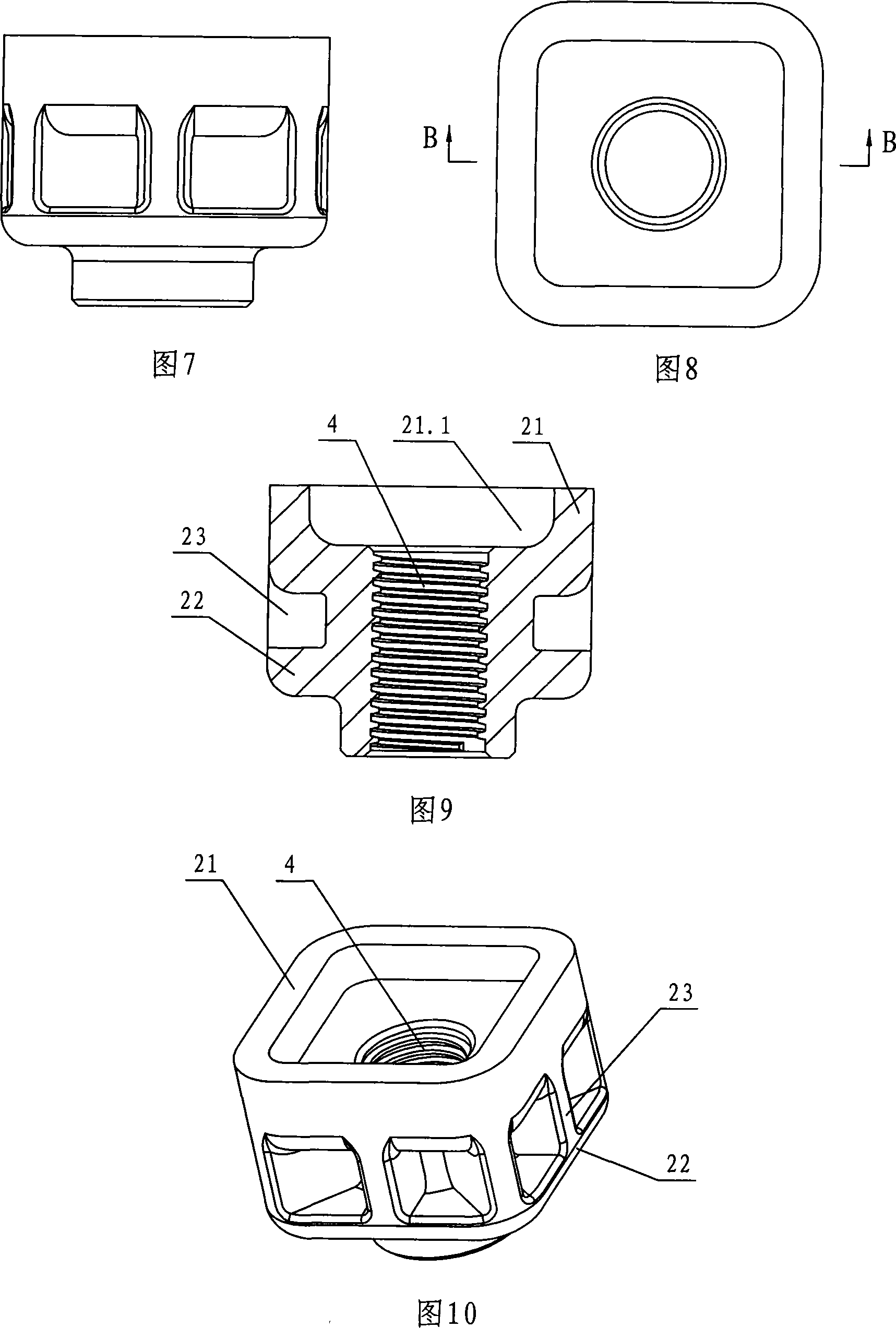

[0032] Referring to Fig. 7-Fig. 10, the second reinforcing rib 23 is a quadrangle, its top edge and the bottom of the upper layer 21 of the second nut join, its bottom edge and the bottom layer 22 top of the second nut join, and its inner side is connected to the second nut. The cylindrical sections in the middle of the nut meet. The second nut is arranged in the square tube 8 of the inner leg, and its four corners are provided with circular arcs. There are eight second reinforcing ribs 23, which are uniformly distributed in the circumferential direction, and wherein, four second reinforcing ribs are facing the four circular arcs.

[0033] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com