Automatic forming method for parallel U-shape lamp tube unit in energy-saving fluorescent lamp tube

A technology of energy-saving fluorescent lamps and molding methods, which can be used in glass molding, glass reshaping, manufacturing of ships or leading wires, etc. It can solve the problems of waste of materials, processing costs, and difficult control and improvement of heating and melting processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

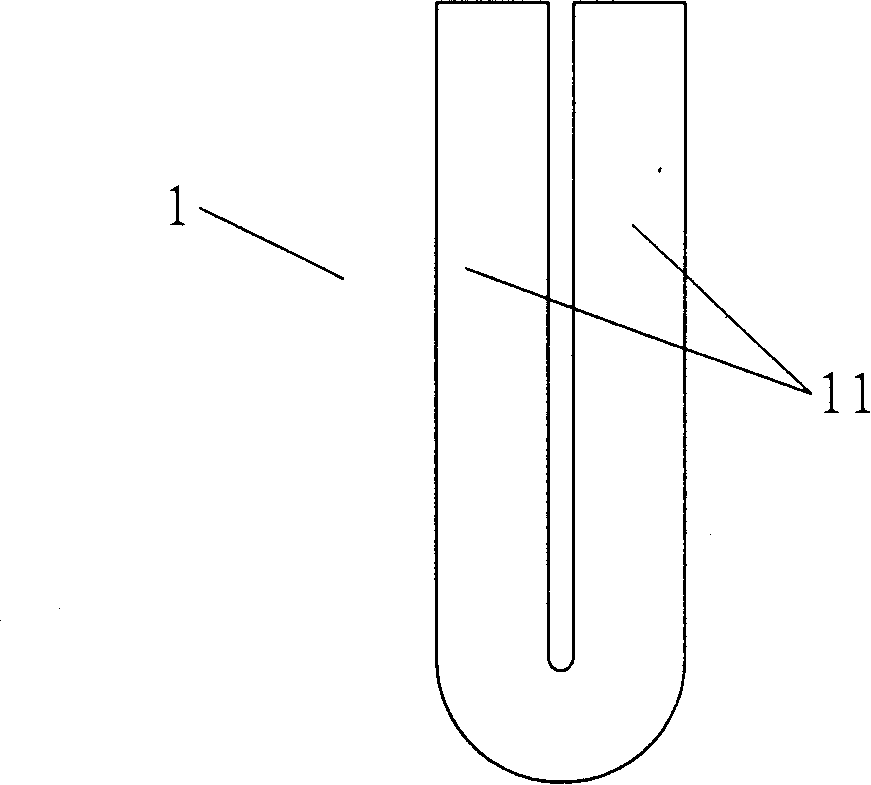

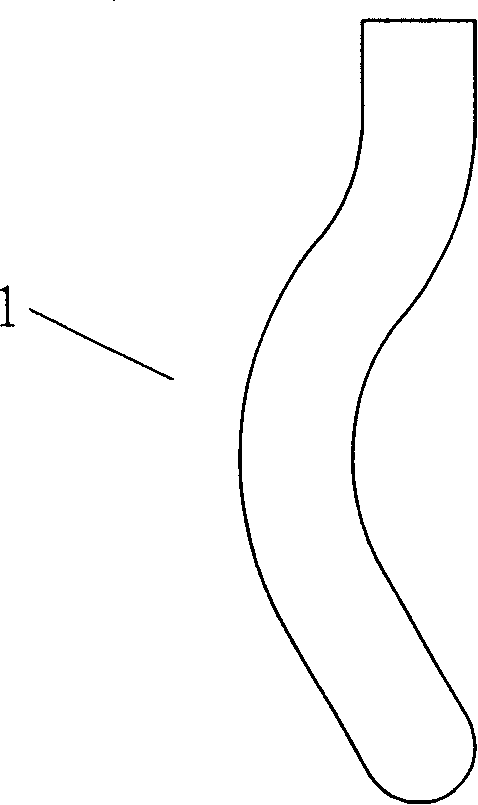

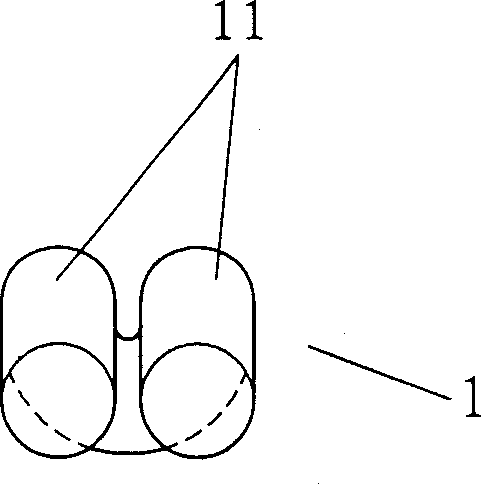

[0021] See Figure 1-3 As shown, it is a preferred embodiment of a single lamp tube unit to be processed and formed in the present invention. As for the lamp tube, it can be combined by four such lamp tube units 1 through bridges. The number of lamp tube units 1 is based on the design of the lamp tube As shown in FIG. 6 , each lamp unit 1 of the present invention is also formed by bending a single U-shaped tube with the help of molds 101 and 102 according to the same arc, so that the side tubes 11 of the same lamp unit 1 between parallel and compact (see figure 1 , 3 ), this paper shows that the arc of the lamp unit 1 is a circular arc (see figure 2 ), can also be quasi-elliptical arc, S-arc and broken line type, etc. (not shown in this article). The tube diameter of the side tube 11 of each lamp tube unit 1 is 6-12 mm. As described in PCT / CN2004 / 000696, each lamp unit 1 is connected by a bridge, and the side tubes 11 of the two lamp units 1 at the head and tail are equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com