Net laying mechanism with compensation function

A technology of laying and function, applied in the field of laying mechanism with compensation function, can solve problems such as hindering the quality of non-woven products, and achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Through the following detailed description of the embodiments, it will be more helpful for the public to understand the present invention, but the specific embodiments given by the applicant cannot and should not be regarded as limitations on the technical solution of the present invention. Changes in the definition of technical features and / or changes to the overall structure that are only formal but not substantive should be regarded as the scope of protection defined by the technical solution of the present invention.

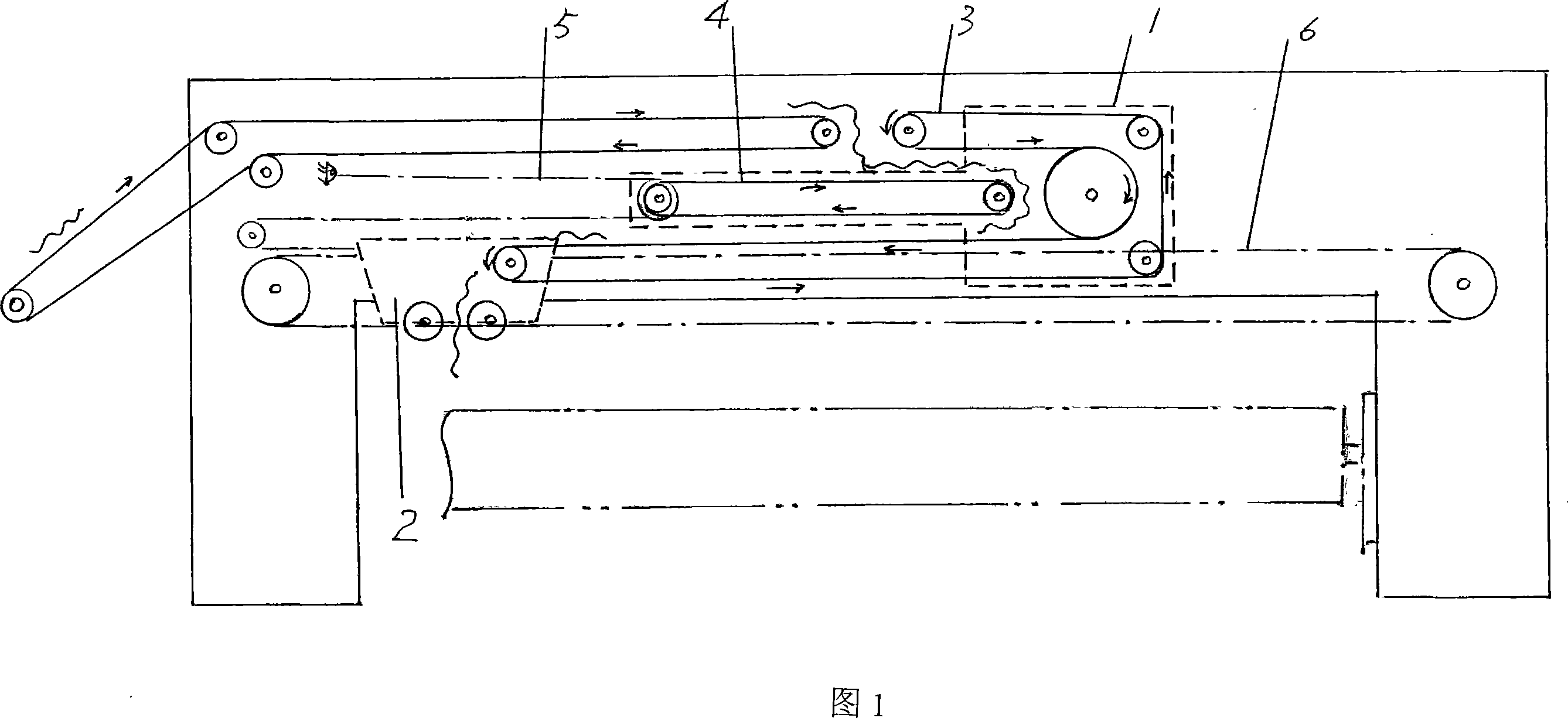

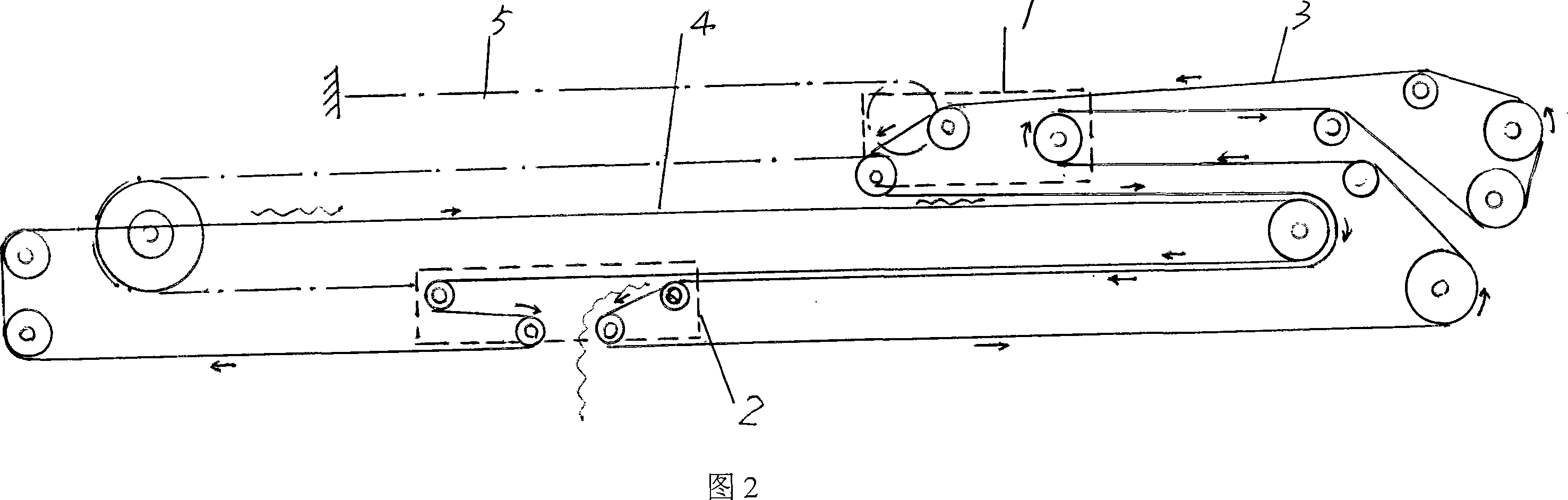

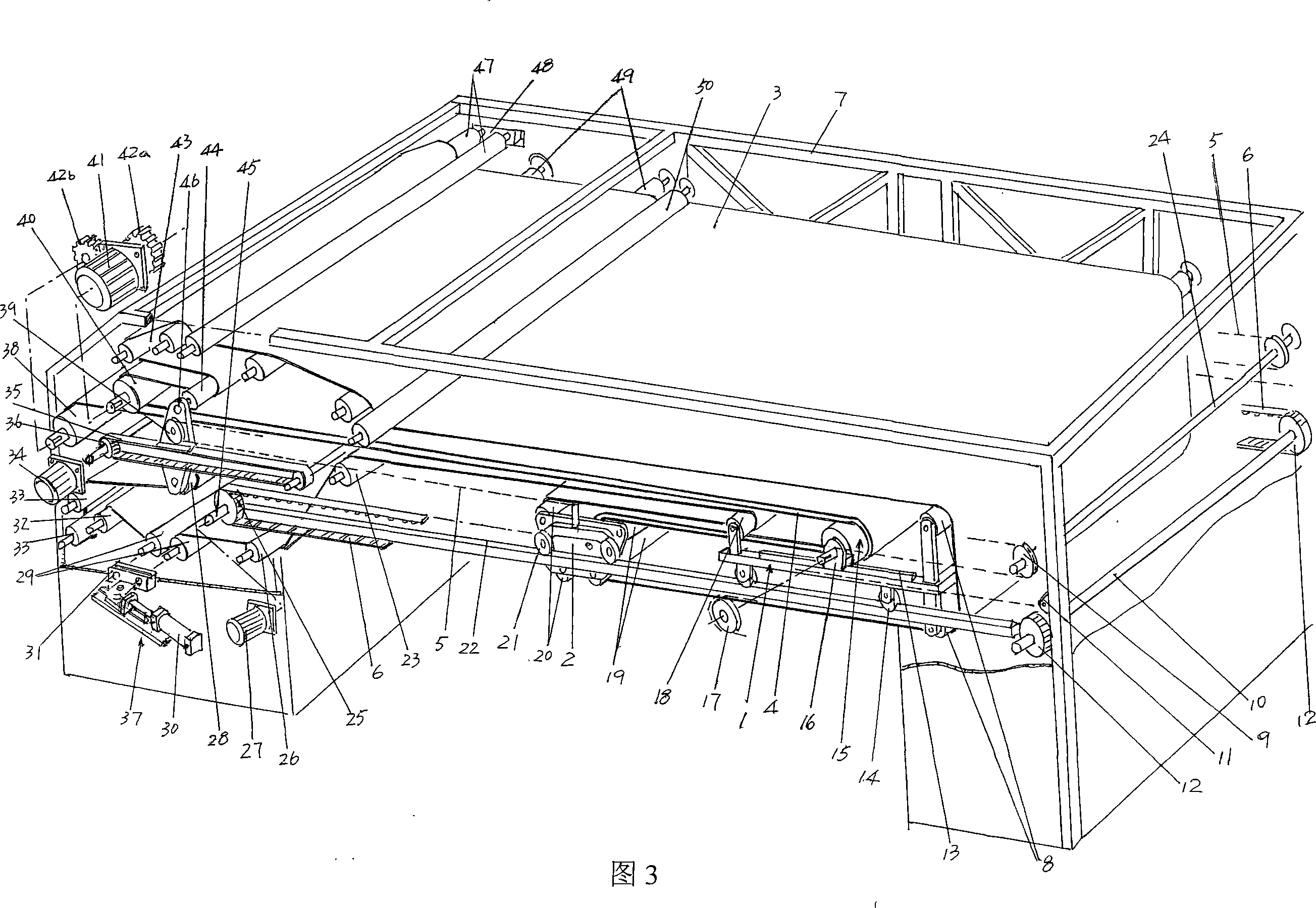

[0027]Please refer to Fig. 3 and Fig. 4, have provided the frame 7 as laying net mechanism, take the current position state shown in Fig. 3, Fig. 4 as example (below the same, repeat no more), before frame 7, The rear side and the upper part each have a pair of guide rails 22 that are identical in shape and consistent with each other in position. On the guide rails 22, the web-laying carts 1 and 2 that are slidably configured with the same structure as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com