Bending-torsional non-linear variable-diameter tube pressed mould manufacture method

A production method and non-linear technology, which is applied in the production field of bending and torsion nonlinear variable-diameter tube pressing molds, can solve the problems of long time period, large error, and high cost, so as to reduce labor intensity, save manpower, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

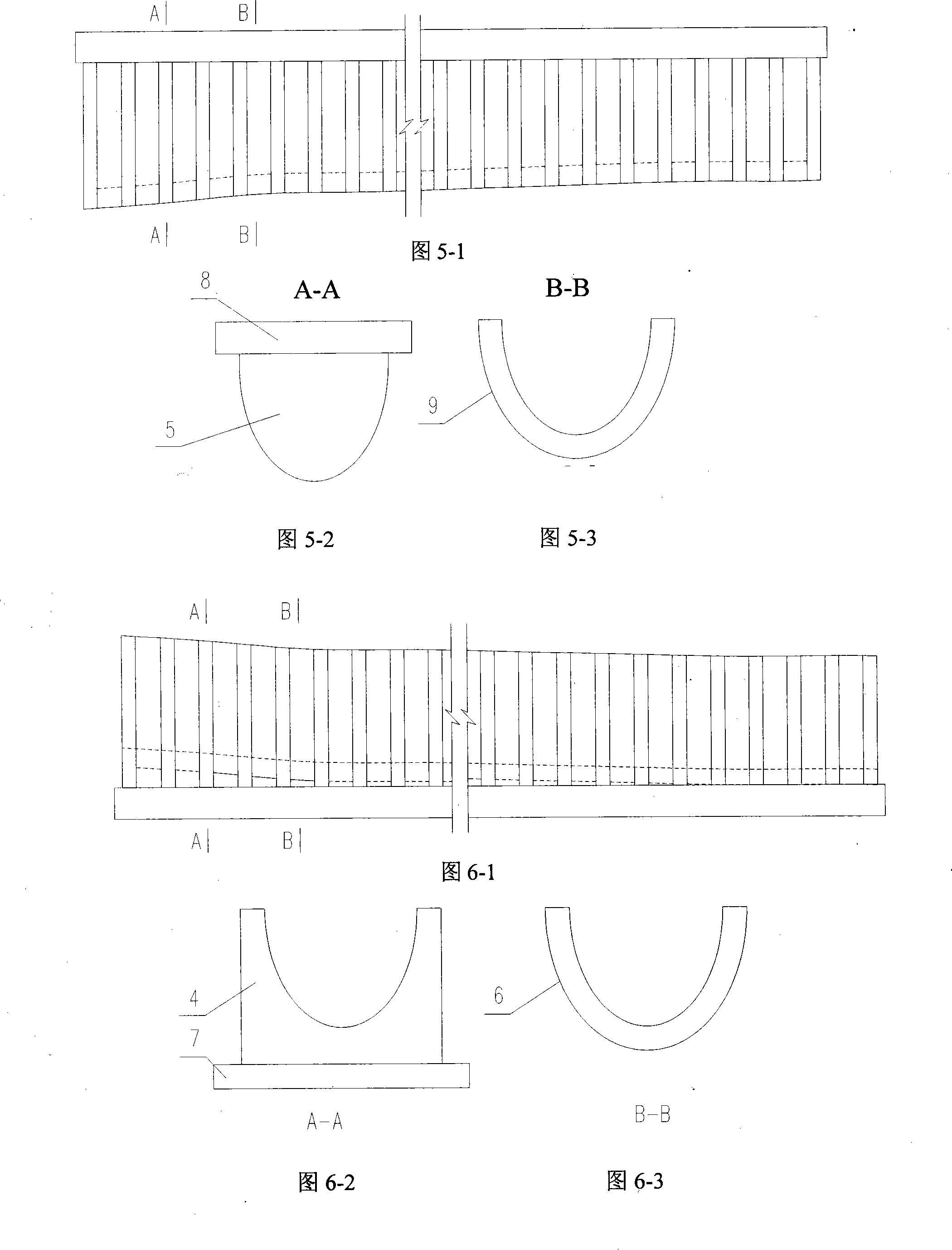

[0024] The manufacturing method of the mold of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

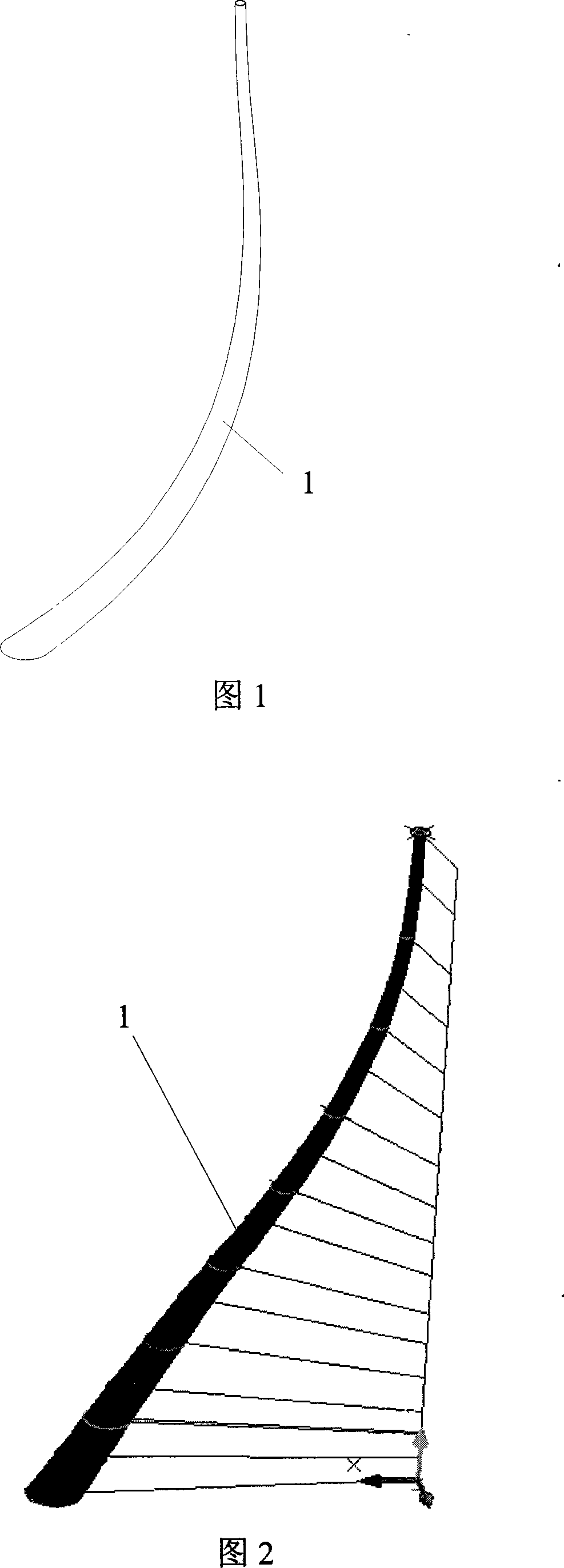

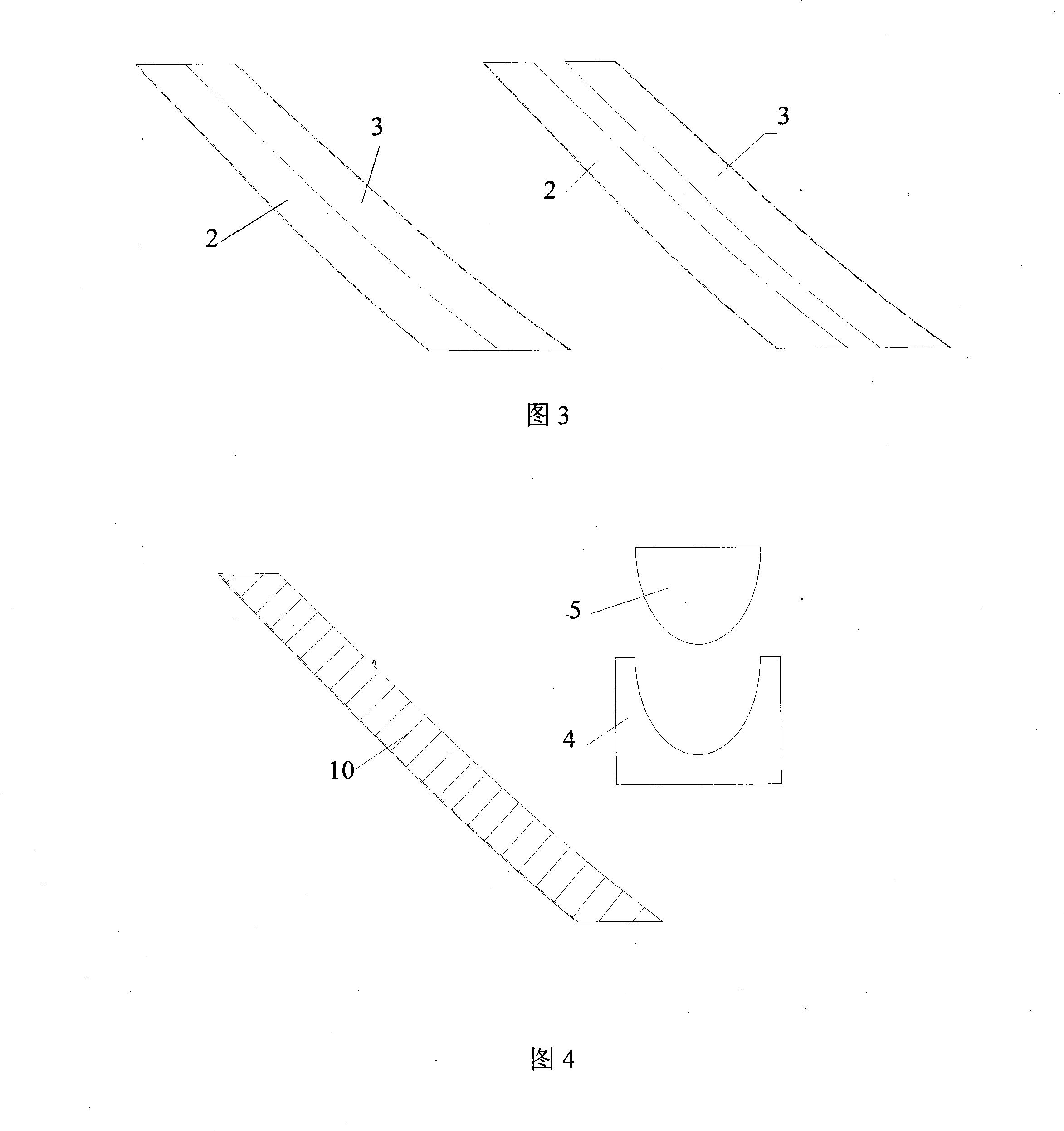

[0025] Utilizing the manufacturing method of the bending and torsion reducing tube of the present invention to press the mold, the steps of making the bending and torsion nonlinear reducing tube 1 as shown in Figure 1 are shown in Figure 7, mainly including the following steps:

[0026] First of all, according to the actual assembly of tubular components, a three-dimensional solid model is established in AutoCAD2007, and several component cross-sectional shapes are drawn at key parts in the model space, and then the "SOFT" command is used to connect each cross-section into a three-dimensional solid, thus Complete the creation of the three-dimensional solid model of the tubular member, as shown in 701 in Figure 7, the three-dimensional solid model is shown in Figure 2;

[0027] If the length of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com